View-field-based monocular depth camera and object shape detection method thereof

A depth camera and single-purpose technology, applied to color TV parts, TV system parts, TVs, etc., can solve problems that affect the accuracy of 3D reconstruction, visible light images and infrared light images have parallax, etc., to improve the system Stability, reduce production cost, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

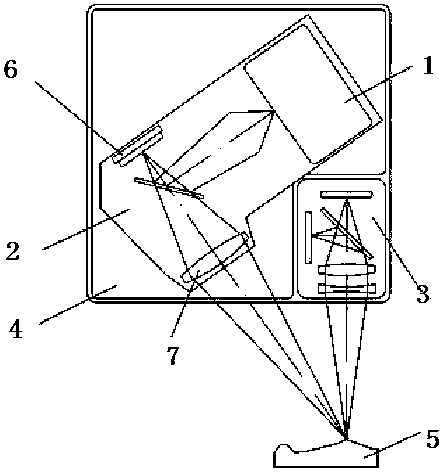

[0031] A monocular depth camera based on field of view matching, including: an infrared and visible composite light source 1, a structured light projection photoelectric engine 2 that encodes structured light and projects it onto an object to be measured 5, and collects textures on the surface of the object to be measured 5 The 3D and 2D real-time fusion optical camera 3 of information receives the near-infrared image sensor and the visible light image sensor of the information of the 3D and 2D real-time fusion optical camera 3, receives the signals of the near-infrared image sensor and the visible light image sensor and obtains the object 5 to be measured The master control of structured light 3D imaging of 3D contour and texture information4.

[0032] The structured light projection photoelectric engine 2 is composed of a structured lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com