Machine tool geometric accuracy optimization method based on value analysis method

An optimization method and geometric precision technology, applied in geometric CAD, computer parts, special data processing applications, etc., can solve problems such as low work efficiency, lack of functional and structural features, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

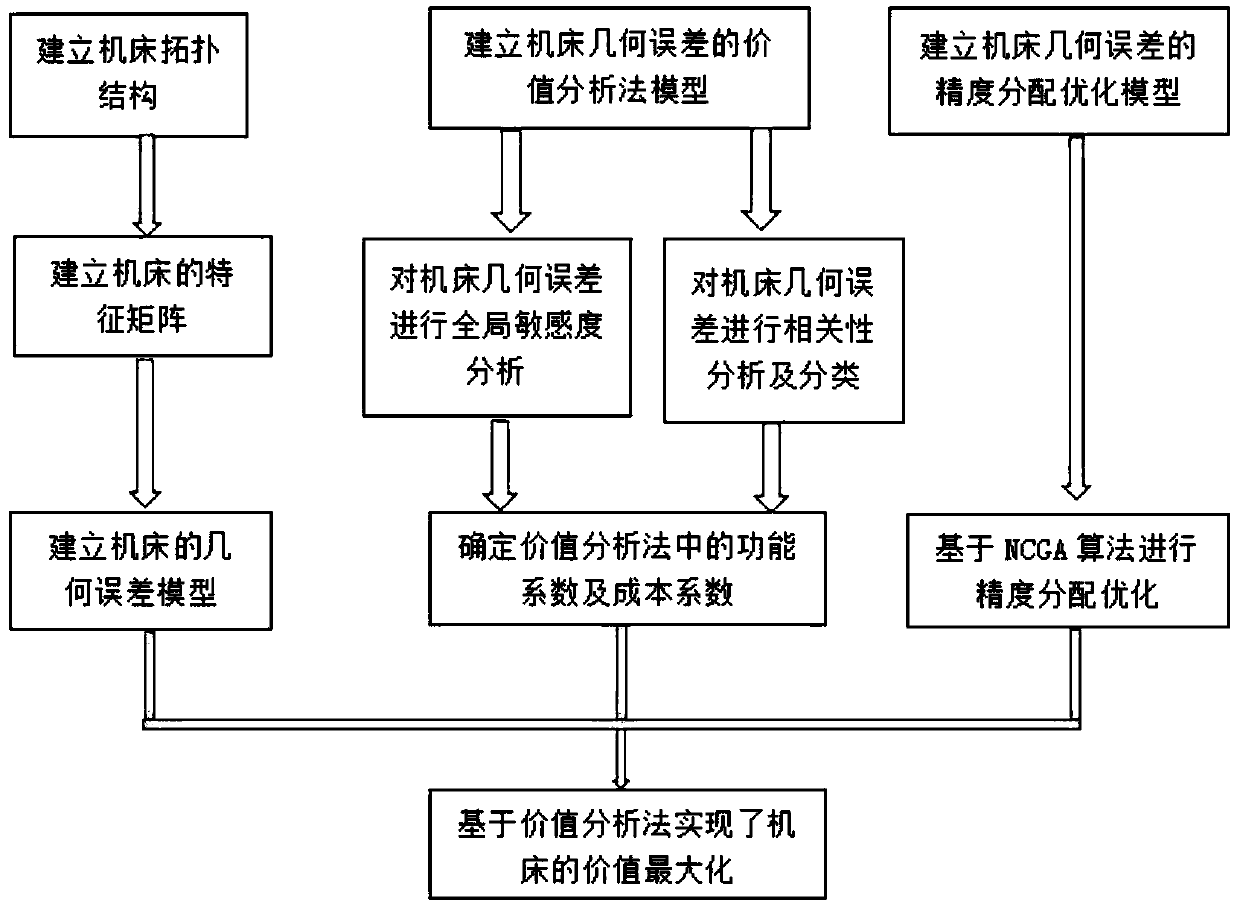

Method used

Image

Examples

Embodiment Construction

[0122] Step 1: Establish geometric error model of precision machining center

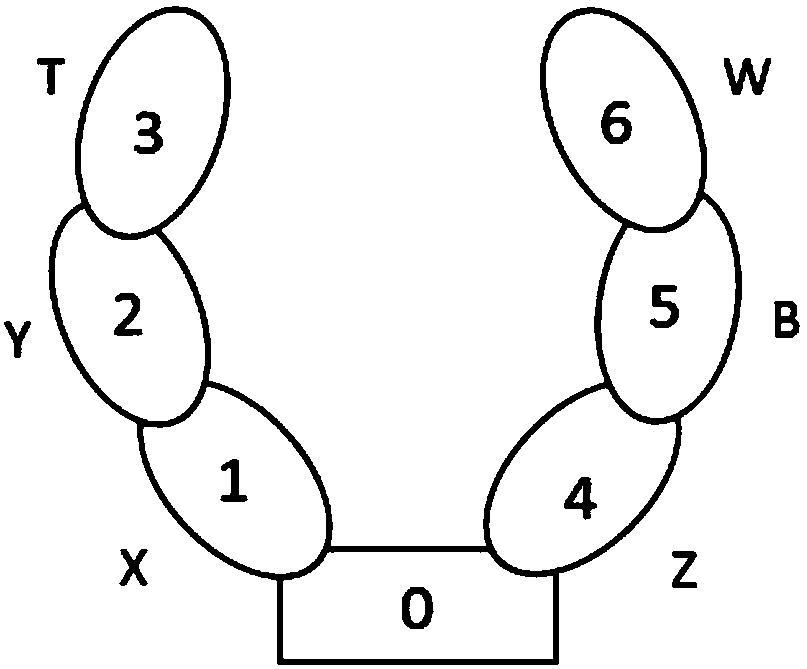

[0123] Step 1.1 establishes the feature matrix of the precision horizontal machining center

[0124] The present invention takes the horizontal coordinate boring machining center JIG630 as an example to model and analyze its geometric error. topology see figure 1 , there are 30 geometric errors including positioning error, straightness error, angle error, etc. The symbols and descriptions of these 30 errors are shown in Table 1. The present invention uses a homogeneous transformation matrix for error modeling, and the homogeneous transformation matrix between the moving parts is shown in Table 2.

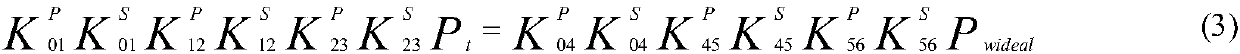

[0125] Step 1.2 Establish geometric error model of precision machining center

[0126] Suppose the coordinates of the tool forming point in the tool coordinate system are:

[0127] P t =(p tx p ty p tz 1) T (33)

[0128] The coordinates of the workpiece forming point in the workpiece coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com