Drug preparing syringe with exhaust function

A syringe and function technology, applied in the field of medical supplies, can solve the problems of liquid splashing outwards, increased resistance of the syringe piston rod, etc., and achieve the effect of ensuring the coaxiality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

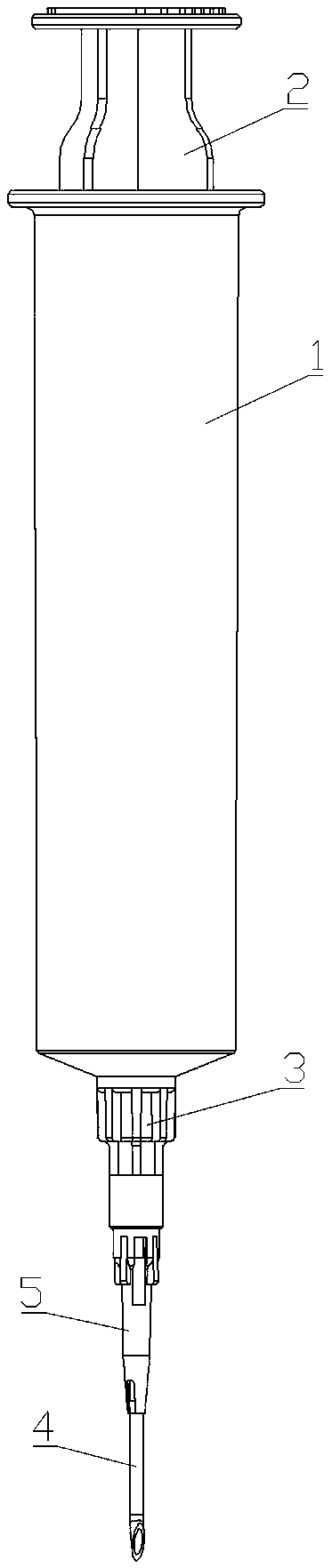

[0021] like Figure 1-4 As shown, the drug dispensing syringe with exhaust function includes a syringe 1 , a piston rod 2 , a needle seat 3 , a needle tube 4 and a ventilation sleeve 5 .

[0022] The syringe 1 is provided with an inner cavity 11 for containing the liquid medicine.

[0023] The piston rod 2 is movably installed in the inner cavity 11 of the syringe 1 , and the size of the inner cavity of the syringe 1 can be changed by pushing and pulling the piston rod 2 .

[0024] A liquid medicine channel 31 is provided in the needle base 3 , the needle base 3 is connected to the syringe 1 , and the liquid medicine channel 31 in the needle base 3 communicates with the inner cavity 11 of the syringe 1 .

[0025] One end of the needle tube 4 is bonded and fixedly installed in the liquid medicine channel 31 of the needle holder 3, and the other end is an exposed end.

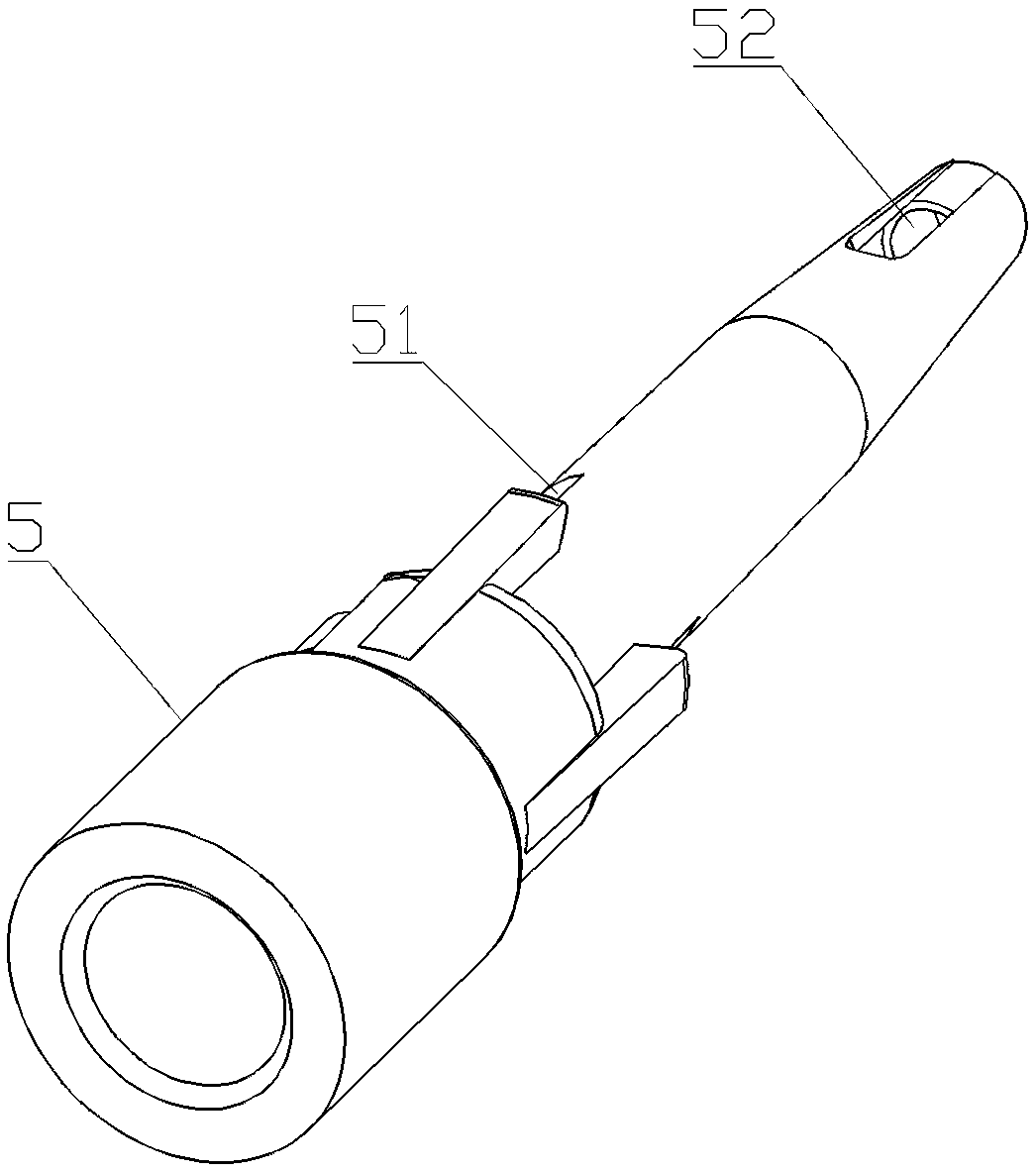

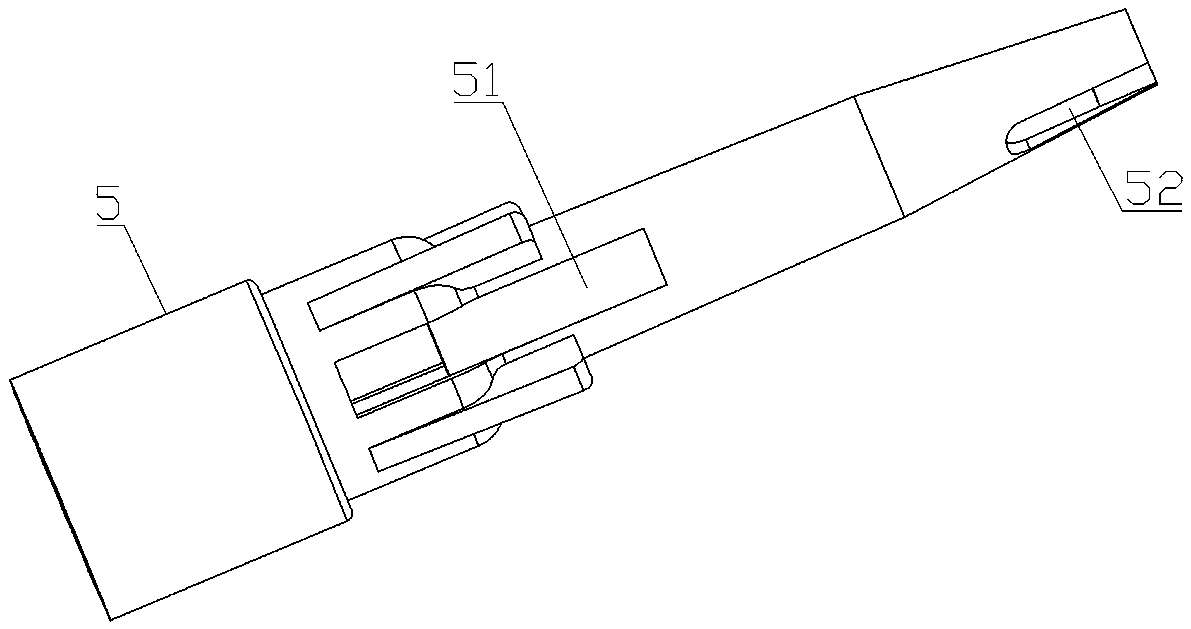

[0026] The upper end of the ventilation sleeve 5 is provided with an exhaust port 51, and the lower end is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com