Atomization tank with anti-inverse-installation device

A technology of anti-installation and atomization core, which is applied in the field of medical devices, can solve the problems of unfavorable disease treatment effect, tilting of atomization tank, waste of liquid medicine, etc., to facilitate large-scale promotion and application, sufficient circulation and convection, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

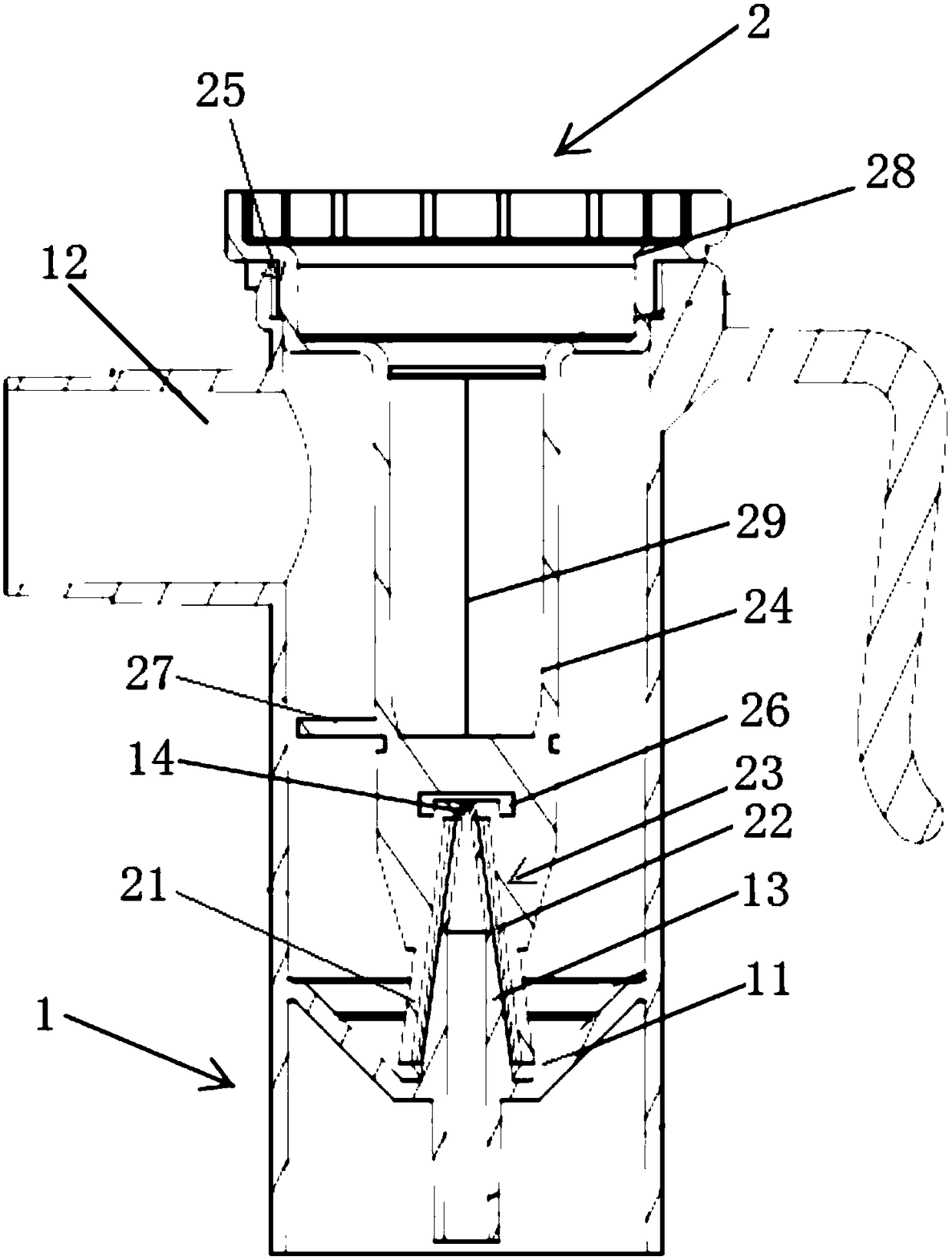

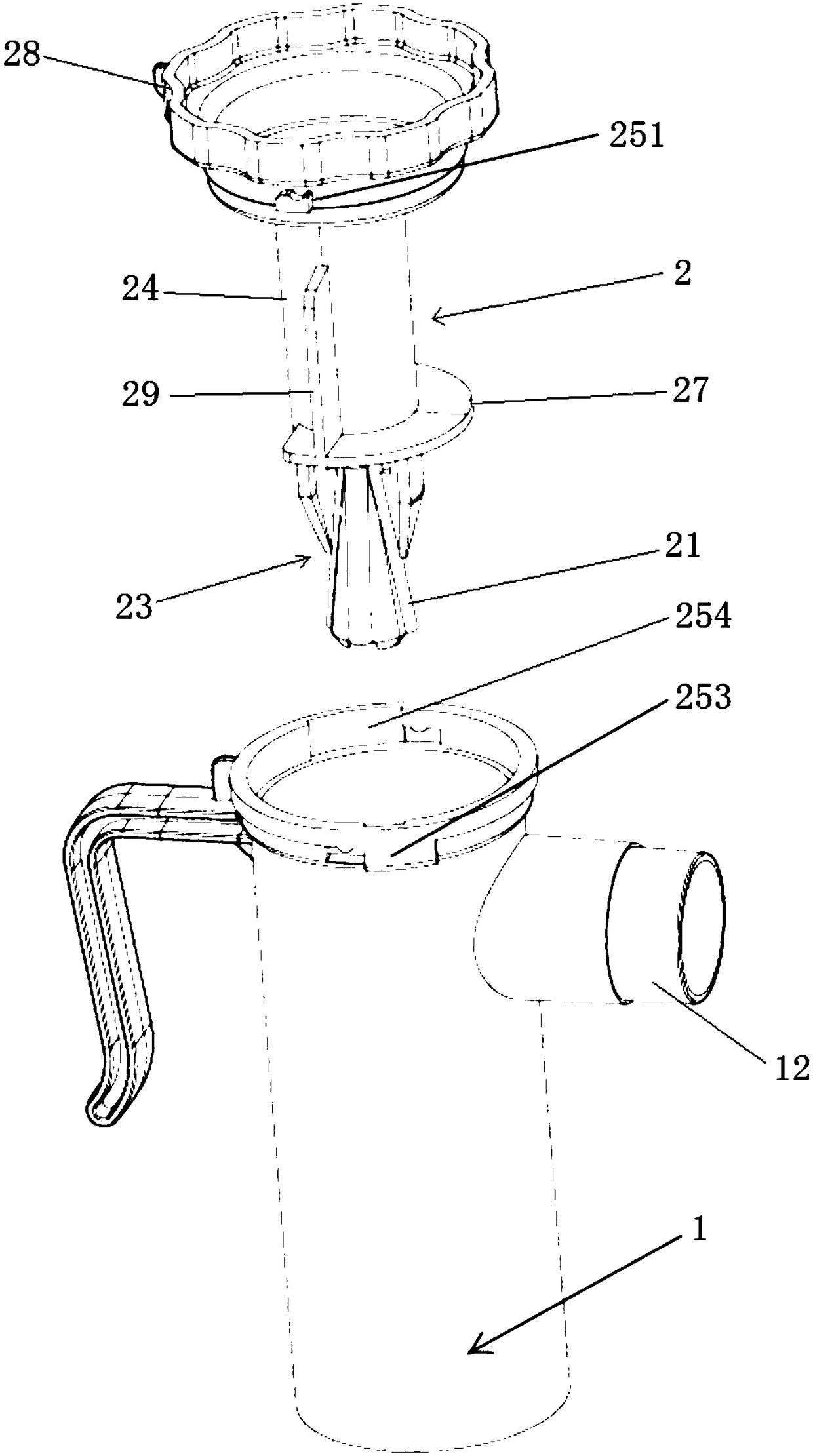

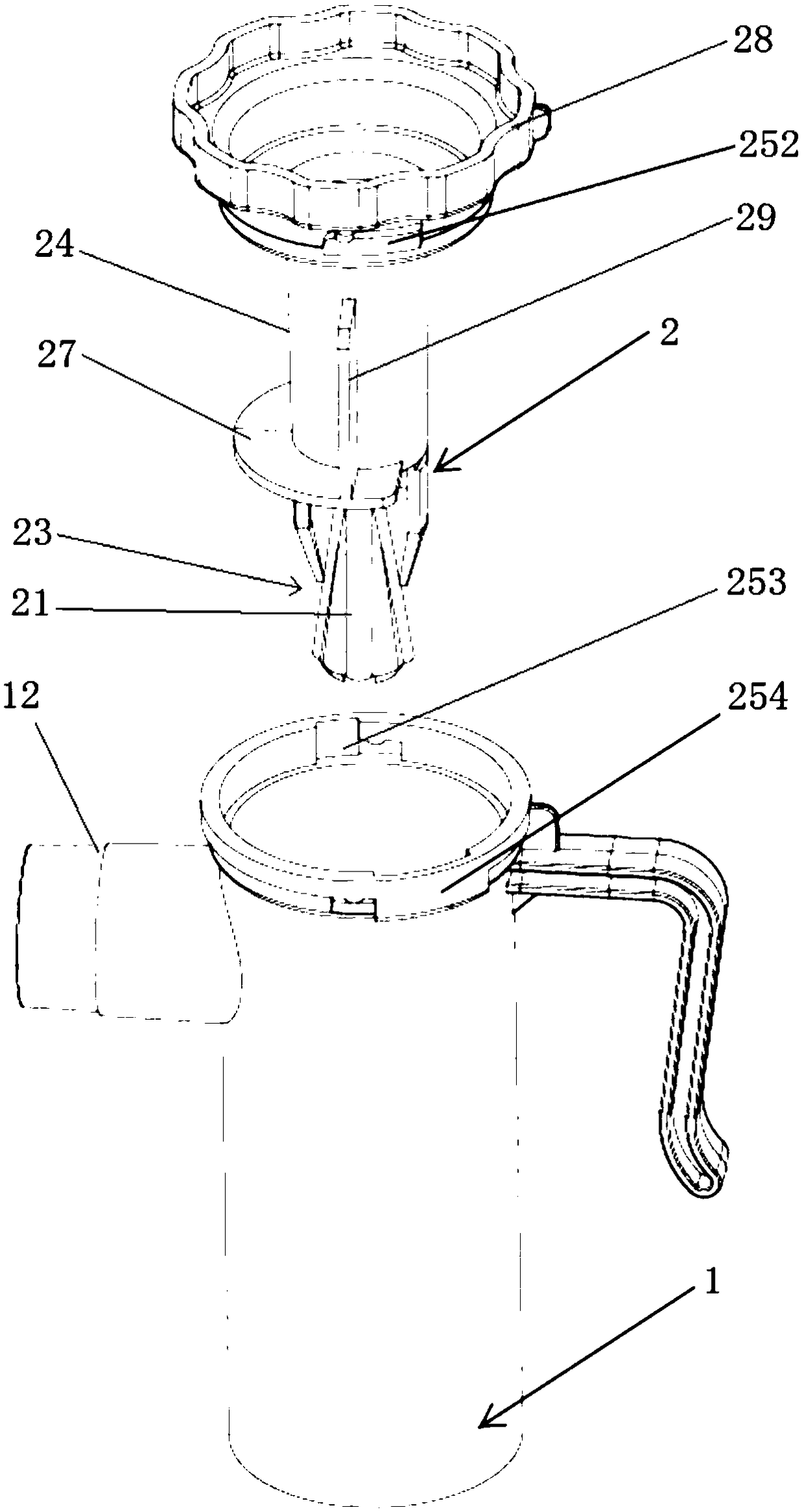

[0020] The specific embodiment of the present invention is like this: as Figure 1-3 As shown, an atomizing tank with an anti-installation device includes a tank body 1, a tank core 2 sealed and inserted in the tank body 1, a liquid medicine storage area 11 is provided at the bottom of the tank body 1, and the tank body 1 One side of the mouthpiece or mask is provided with a medicine mist outlet 12 connected to the mouthpiece or a mask. The center of the medicine liquid storage area 11 is provided with a cone-shaped vertical air nozzle 13 connected to an external air source. The top of the air nozzle 13 is provided with an air jet. Holes 14; the tank core 2 is provided with an air inlet pipe 24, the bottom of the tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com