Compaction and injection mechanism of soil sampling and remedying integrated drilling machine

A soil sampling and integrated technology, applied in the field of contaminated soil remediation, can solve the problems of not so perfect treatment effect, inconvenient disassembly and assembly of pressure gauges and ball valves, uncontrollable pipeline pressure, etc., to achieve convenient and safe disassembly and assembly , Deep injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below with reference to accompanying drawing and in conjunction with embodiment, structural feature and technical implementation process of the present invention are described in detail:

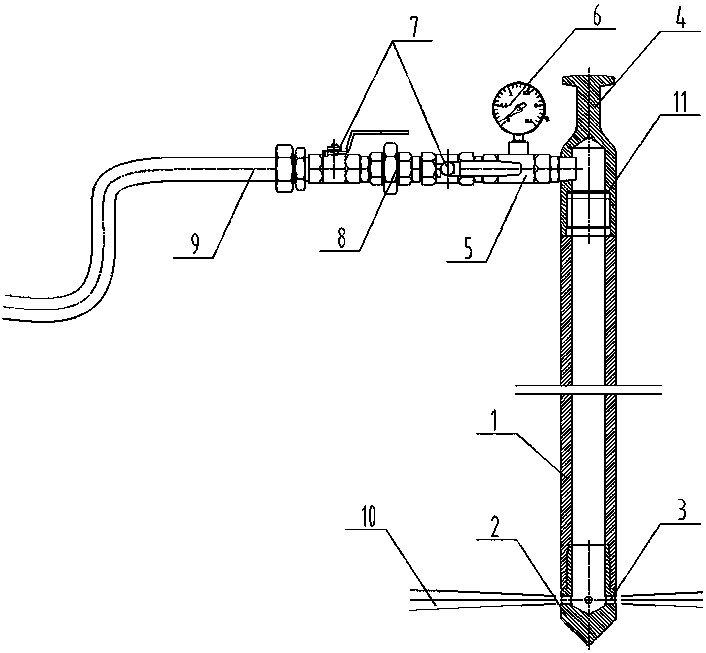

[0018] Such as figure 1 As shown, a compaction injection mechanism of a soil sampling and repairing integrated drilling rig includes an outer pipe 1 of a soil-taking pipe, and a lifting joint 4 is connected to the top of the outer pipe 1 of the soil-taking pipe, and the outer pipe 1 of the soil-taking pipe and the lifting joint 4 An injection channel is provided inside, and one side interface of the three-way joint 5 is connected to one side of the lifting joint 4, and a pressure gauge 6 is connected to the middle interface of the three-way joint 5, and the other side of the three-way joint 4 The interface is sequentially connected with a first ball valve 7 and a second ball valve 12, a joint 8 is connected between the first ball valve 7 and the second ball valve 12, and a grouting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com