Feedforward compensation method and system for inlet tension through design flow and thickness control

A technology of thickness control and feed-forward compensation, applied in rolling mill control device, tension/pressure control, metal rolling, etc., can solve the problems of decreasing product yield, increasing strip out-of-tolerance length, influence of control accuracy, etc. Accuracy, improve yield, weaken the effect of strong coupling relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

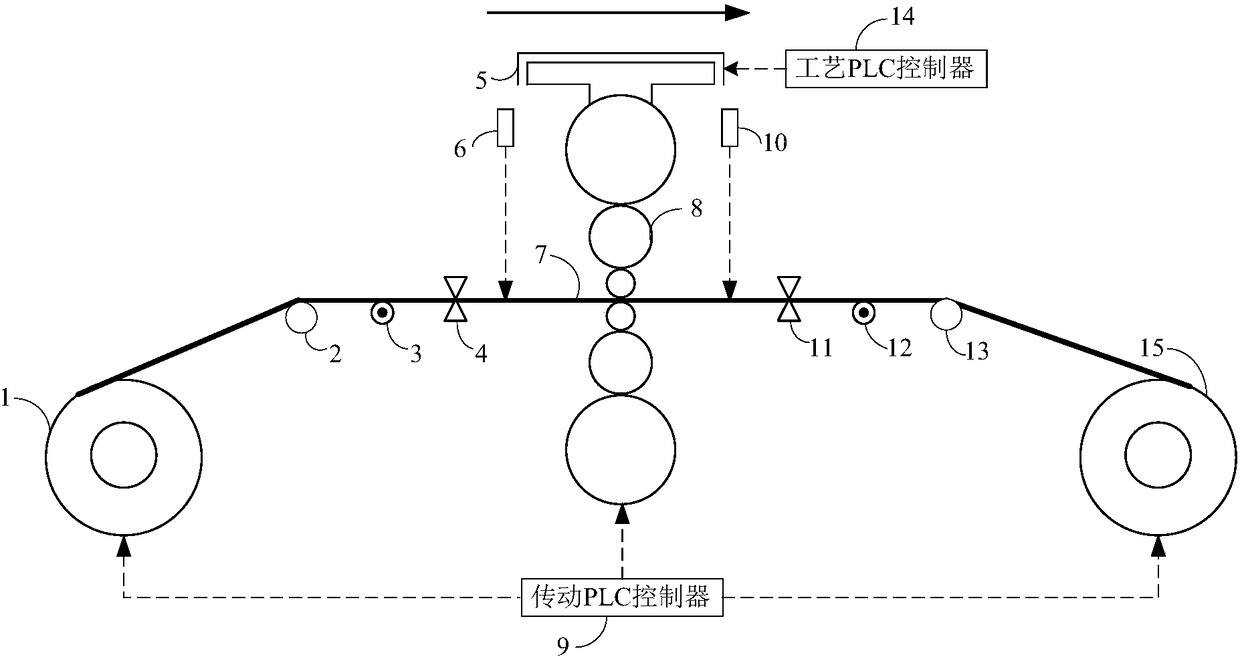

[0034] Such as figure 1 As shown, the strip steel 7 is uncoiled from the entrance coiler 1, enters the six-roll mill 8 after passing through the entrance turning roll 2 for rolling, passes through the exit turning roll 13 after rolling, and is coiled on the exit coiler 15, and the strip steel 7 Thickness control is programmed in the process PLC controller 14, and the process PLC controller 14 controls the hydraulic cylinder 5 to provide rolling force to roll the strip steel 7 to the required thickness; the entrance and exit are configured to measure the thickness of the strip steel 7 at the entrance and exit The entrance thickness gauge 4 and the exit thickness gauge 11, the entrance and exit are also equipped with an entrance tension gauge 3 and an exit tension gauge 12 for measuring the tension at the entrance and exit of the strip steel 7; the entr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com