Pulse-type feeding mechanism for conveying porcelain columns

A feeding mechanism and pulse-type technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low supply accuracy, complex transmission and feeding structure, high failure rate, etc., and achieve high intelligence and high transmission efficiency The effect of high and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

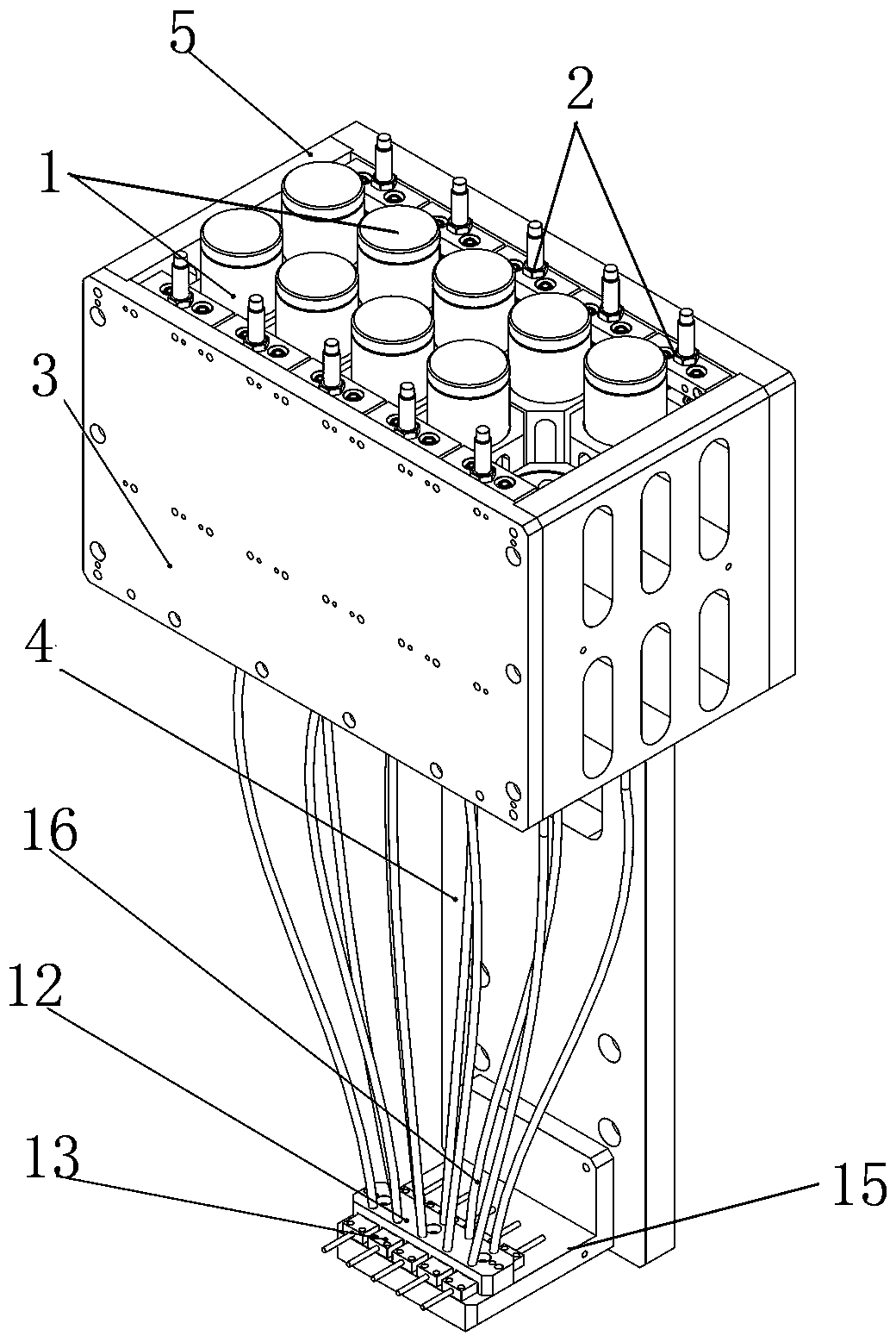

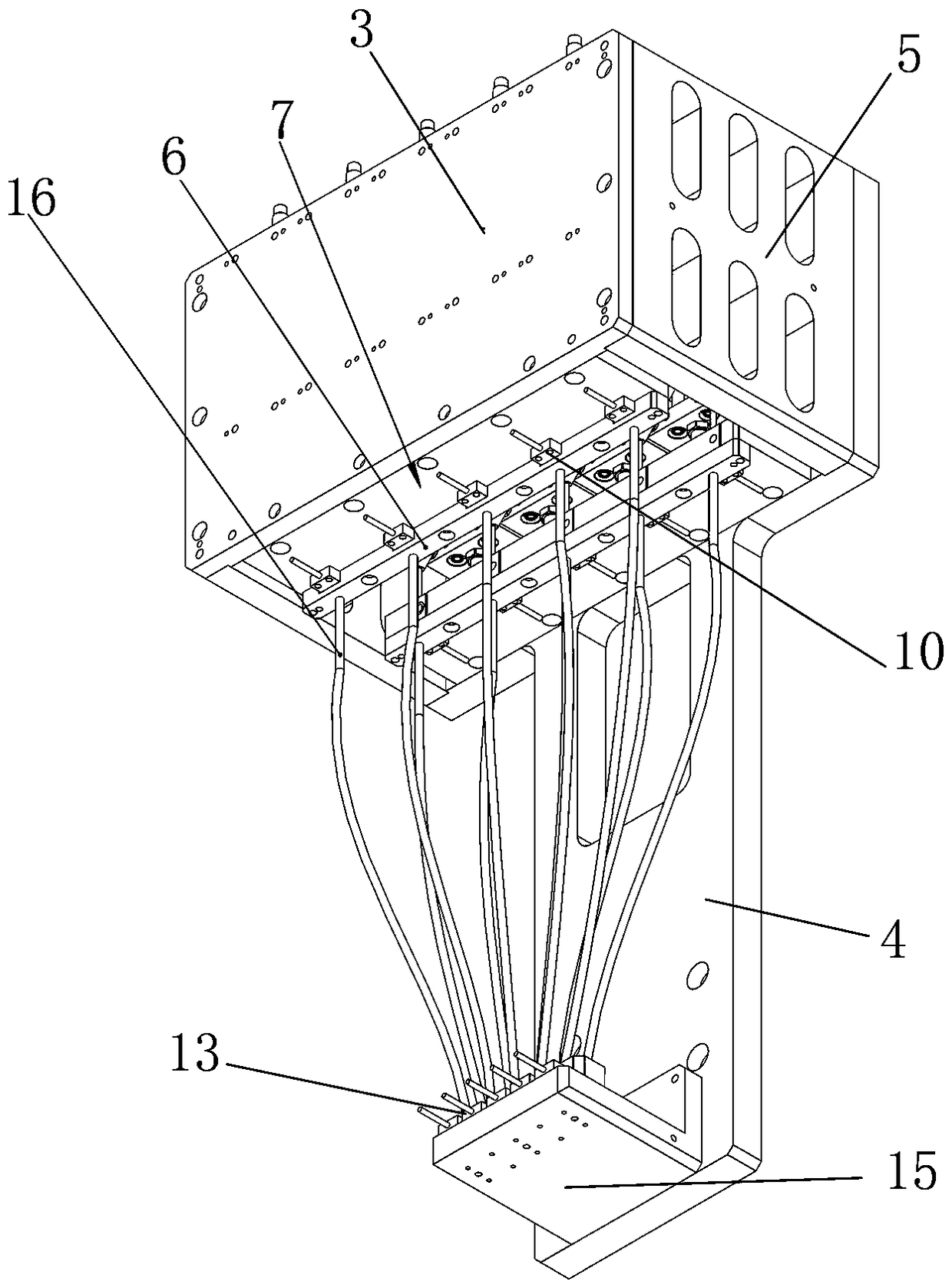

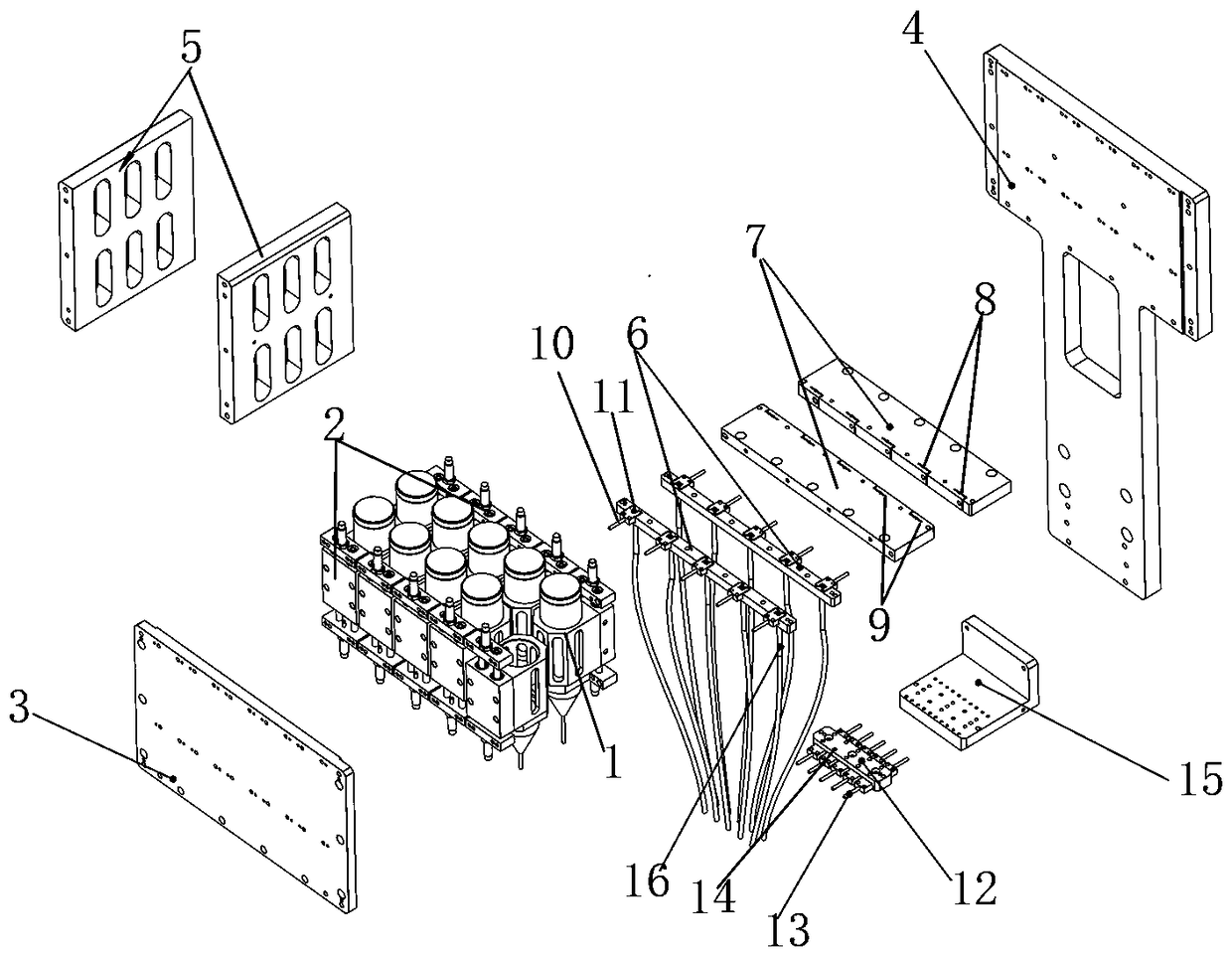

[0031] In this embodiment, refer to Figure 1-Figure 7 , the concrete implementation of the pulse feeding mechanism for conveying porcelain columns includes a bin assembly 1, a lifting cylinder 2 for driving the bin assembly 1 to lift and move, and a bin guard plate, and the lifting cylinder 2 and the bin assembly 1 Combined to form a group of automatic feeding components, the silo guard plate includes a front guard plate 3, a rear guard plate 4 and a side guard plate 5, and the front guard plate 3, the rear guard plate 4 and the side guard plate 5 are combined to form a Square chambers for feeding components such as Figure 1-Figure 3 As shown, in this embodiment, ten groups of automatic feeding components with the same structure are arranged in the square chamber, and the ten groups of automatic feeding components are neatly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com