Camellia fruit husking machine

A fruit peeling machine, camellia technology, applied in the field of camellia fruit automatic peeling machine, can solve the problems of manual crushing, poor crushing and sorting effect, and large labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

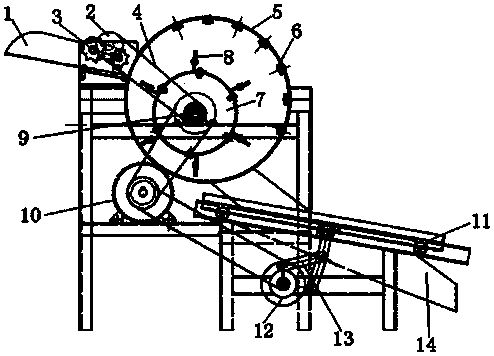

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] The structure of the camellia sheller provided by the present invention is shown in Figure 1. It consists of a rolling device, a centrifugal device, a screening device, a power device and a bracket, and each device is fixedly installed on the frame. Among them, the camellia fruit enters from the feed port 1, and after being processed by the rolling device, the centrifugal device, and the screening device in turn, the tea seeds are obtained, and the tea seeds are discharged from the discharge port 14. Described rolling device is positioned between the feed port 1 of peeling machine and the inlet of centrifuge device, comprises two pressure rollers 3, one large and one small, that are installed on the frame, and big pressure roller is in front, and little pressure roller is in front. Finally, there is a transmission wheel 2 between the big and small pressure rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com