A process for processing corrugated paper using waste paper and coconut bran

A technology of corrugated paper and coir peat, which is applied in the field of corrugated paper processing, can solve the problems of limited waste paper resources and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

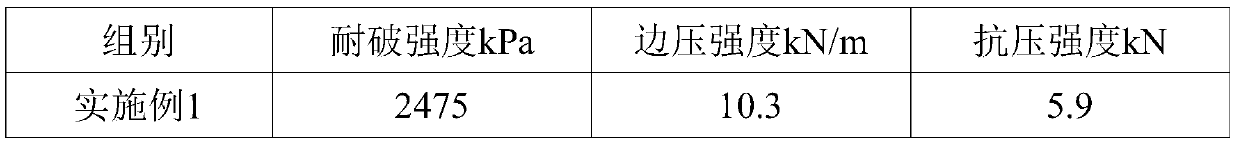

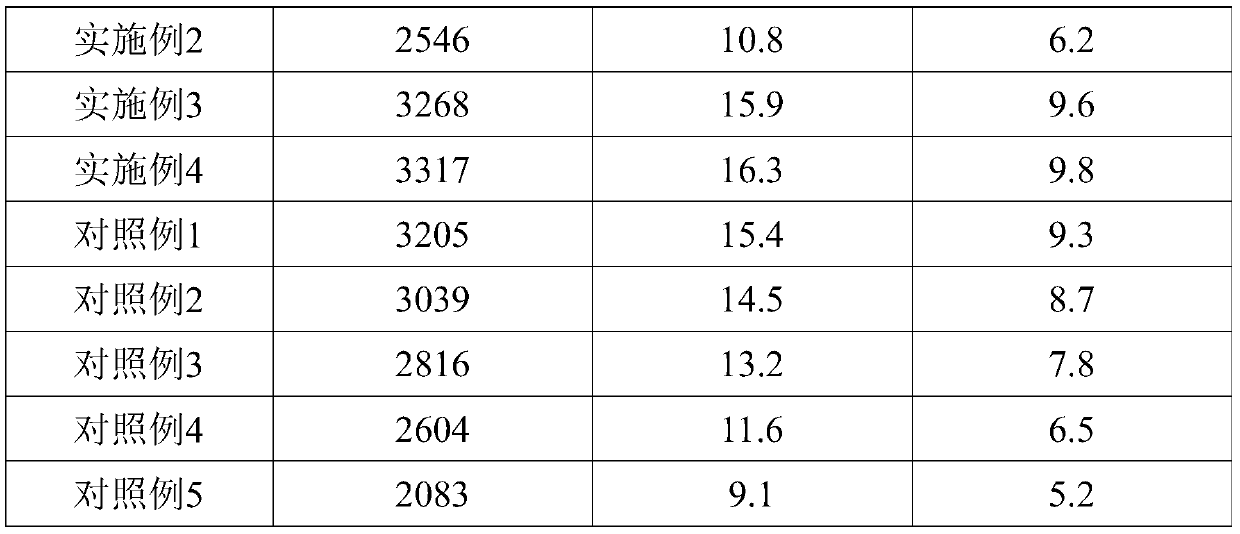

Examples

Embodiment 1

[0027] (1) Dehydration of coconut bran: place coconut bran in a 55-65°C oven for constant temperature dehydration, so that the water content of coconut bran is reduced to below 3wt%, and make 80-mesh coconut bran powder through a pulverizer;

[0028] (2) Pulping: the waste paper is made into 100-mesh waste paper powder through a pulverizer, and then 10kg of waste paper powder is added to the beater, and water is injected into the beater, and a uniform pulp is made through sufficient beating, and then 2kg of coconut bran is added Flour and 0.1kg sweet potato starch, continue beating to obtain a uniform slurry, the gained slurry is added in the refiner, the unbroken slurry is ground through the refiner, and finally the slag is removed by the slag remover;

[0029] (3) Dehydration: pump the prepared slurry to the wire section for forming and dehydration until the dryness reaches 15-25%, and the formed slurry is transported to the press section for dehydration until the dryness rea...

Embodiment 2

[0033] (1) Dehydration of coconut bran: place coconut bran in a 55-65°C oven for constant temperature dehydration, so that the water content of coconut bran is reduced to below 3wt%, and make 80-mesh coconut bran powder through a pulverizer;

[0034] (2) Pulping: the waste paper is made into 100-mesh waste paper powder through a pulverizer, and then 15kg of waste paper powder is added to the beater, and water is injected into the beater, and a uniform pulp is made by sufficient beating, and then 3kg of coconut bran is added Flour and 0.2kg sweet potato starch, continue beating to obtain a uniform slurry, the gained slurry is added in the refiner, the unbroken slurry is ground through the refiner, and finally the slag is removed through the slag remover;

[0035] (3) Dehydration: pump the prepared slurry to the wire section for forming and dehydration until the dryness reaches 15-25%, and the formed slurry is transported to the press section for dehydration until the dryness rea...

Embodiment 3

[0039] (1) Dehydration of coconut bran: place coconut bran in a 55-65°C oven for constant temperature dehydration, so that the water content of coconut bran is reduced to below 3wt%, and make 80-mesh coconut bran powder through a pulverizer;

[0040] (2) Pulping: the waste paper is made into 100-mesh waste paper powder through a pulverizer, and then 15kg of waste paper powder is added to the beater, and water is injected into the beater, and a uniform pulp is made by sufficient beating, and then 3kg of modified pulp is added. Coconut bran powder and 0.2kg sweet potato starch, continue beating to obtain a uniform slurry, the gained slurry is added in the refiner, the unbroken slurry is ground through the refiner, and finally the slag is removed through the slag remover;

[0041] (3) Dehydration: pump the prepared slurry to the wire section for forming and dehydration until the dryness reaches 15-25%, and the formed slurry is transported to the press section for dehydration until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com