A kind of epoxy resin permeable pavement material and preparation method thereof

An epoxy resin and permeable pavement technology, applied in the field of permeable pavement materials, can solve the problems of undisclosed permeable pavement water permeability, increase the viscosity of epoxy resin, undisclosed hardener, etc., and achieve high construction safety and use safety. Excellent strength and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

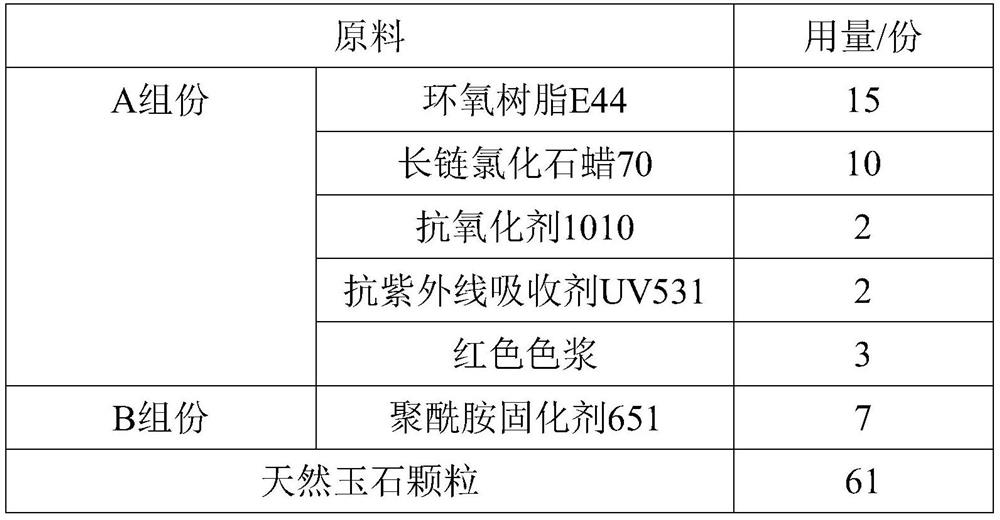

[0023] Weigh each raw material according to the table below.

[0024]

[0025] Preparation of epoxy resin permeable pavement material:

[0026] (1) Start the disperser, add epoxy resin E44, long-chain chlorinated paraffin 70, antioxidant 1010, anti-ultraviolet absorber UV531 and red color paste in proportion, stir evenly, and obtain component A;

[0027] (2) Keep the polyamide curing agent 651 sealed and stored as component B;

[0028] (3) Add natural jade particles to component A, stir well, then add component B, stir well again, and get epoxy resin permeable pavement material.

Embodiment 2

[0030] Weigh each raw material according to the table below.

[0031]

[0032] Preparation of epoxy resin permeable pavement material:

[0033] (1) Start the disperser, add epoxy resin E44, long-chain chlorinated paraffin 52, antioxidant 1010, anti-ultraviolet absorber UV531 and yellow color paste in proportion, and stir evenly to obtain component A;

[0034] (2) Seal and preserve the amino-terminated polyether curing agent ED600 as component B;

[0035] (3) Add natural jade particles to component A, stir well, then add component B, stir well again, and get epoxy resin permeable pavement material.

Embodiment 3

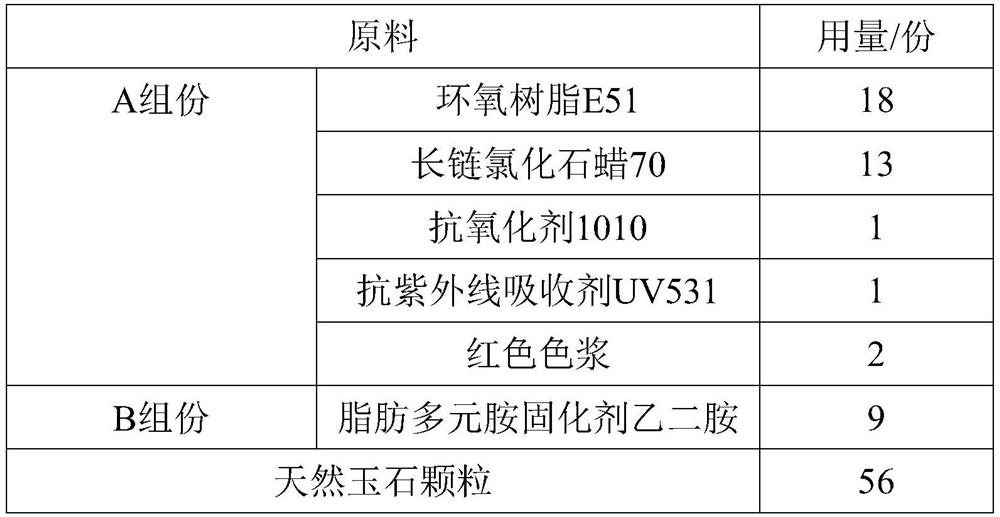

[0037] Weigh each raw material according to the table below.

[0038]

[0039] Preparation of epoxy resin permeable pavement material:

[0040] (1) Start the disperser, add epoxy resin E51, long-chain chlorinated paraffin 70, antioxidant 1010, anti-ultraviolet absorber UV531 and red color paste in proportion, and stir evenly to obtain component A;

[0041] (2) Keep the fatty polyamine curing agent ethylenediamine sealed and preserved as component B;

[0042] (3) Add natural jade particles to component A, stir well, then add component B, stir well again, and get epoxy resin permeable pavement material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com