Coral sand stratum barrel-shaped foundation reinforcing device based on MICP and mounting method

A barrel-shaped foundation and reinforcement device technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as pollution, and achieve the effect of increasing cementation, bearing capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

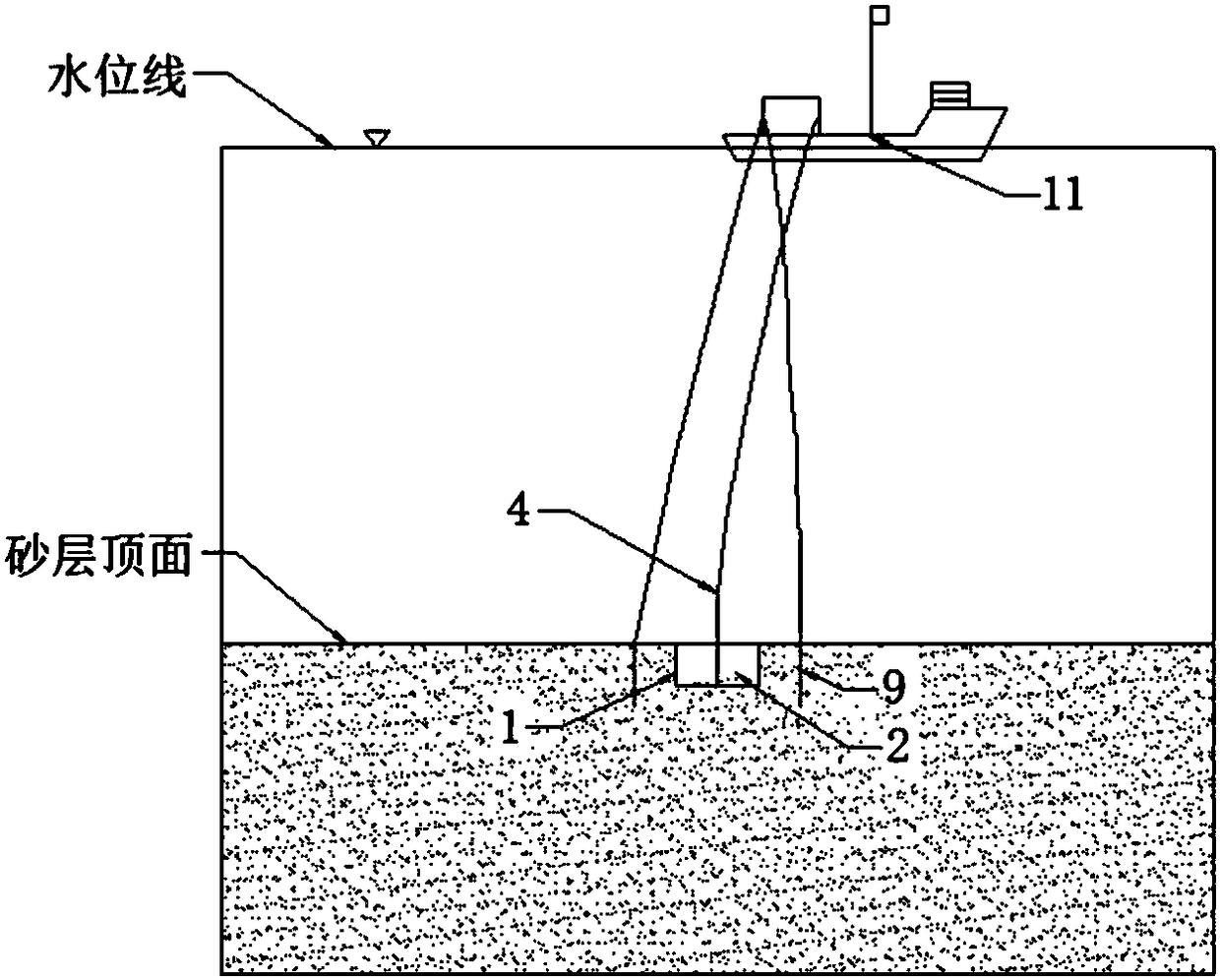

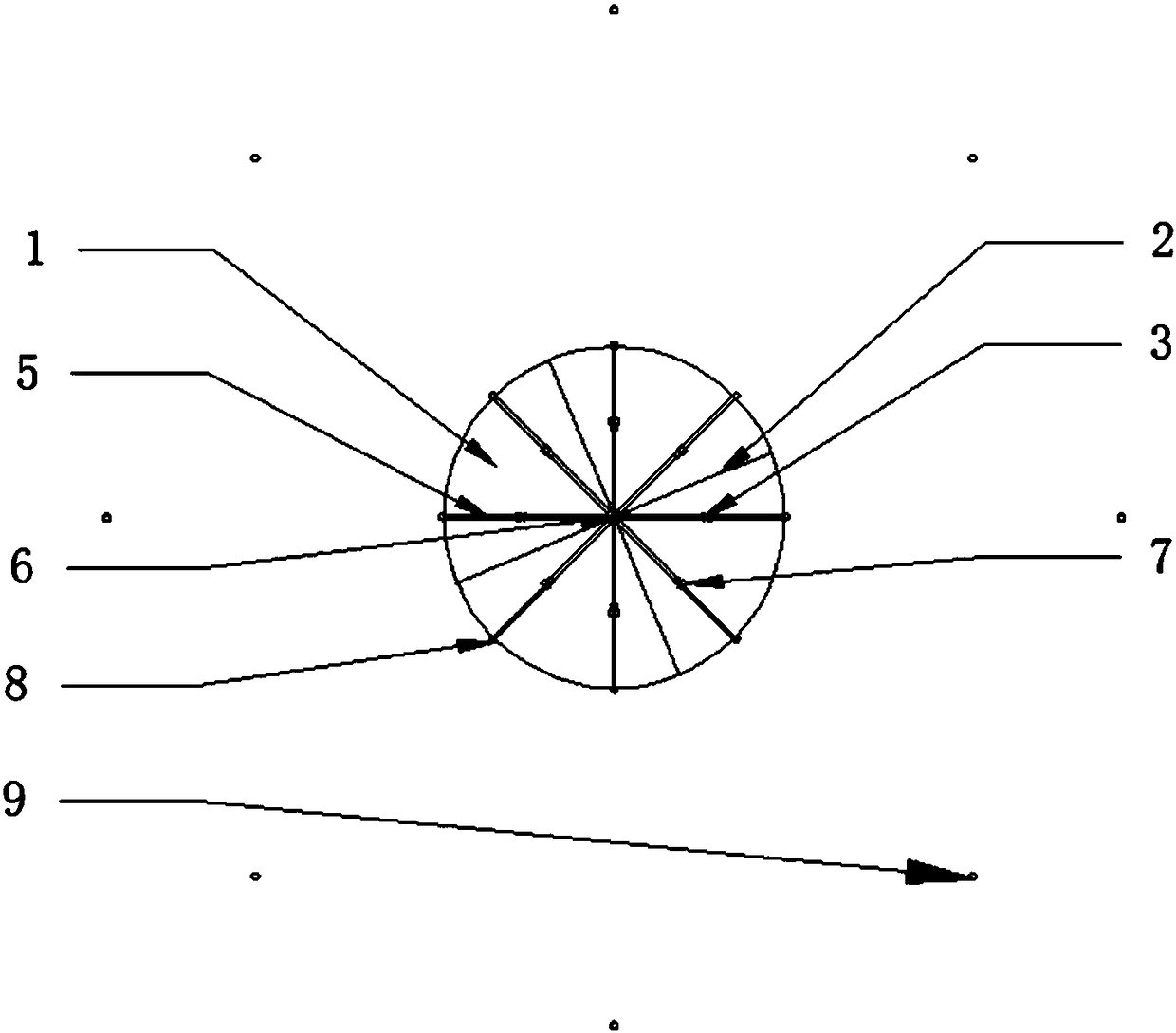

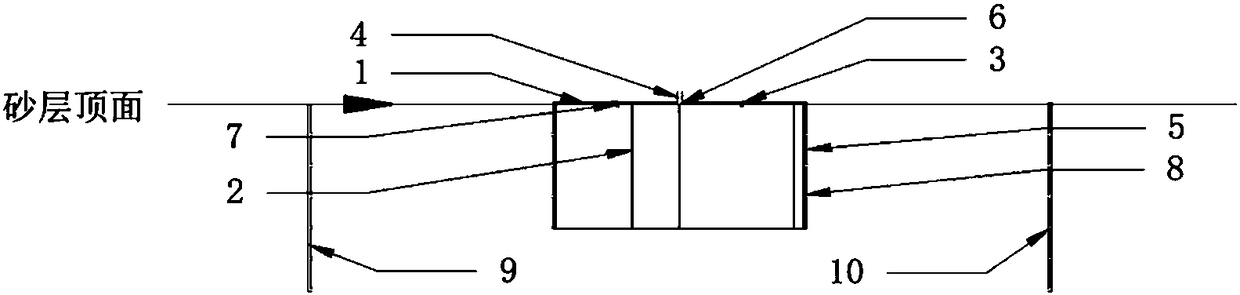

[0021] refer to Figure 1-4 , the barrel-shaped foundation 1 is a suction barrel-shaped foundation with a length-to-diameter ratio of 1:2. There is a cross-shaped partition 2 inside to strengthen the overall strength and rigidity of the structure. The partition 2 divides the barrel-shaped foundation into four partitions. The roof of each compartment has two water pumping holes 3 (also top grouting holes) at 1 / 2 of the radius, and the angle included between the two drain holes 3 and the center line of the top plate is 45 degrees. The grouting main pipe 4 is connected from the construction ship to the center of the top of the foundation, and is connected to the joints 6 of the eight grouting steel pipes 5. The eight grouting steel pipes 5 are arranged in a "meter" shape, and each grouting steel pipe 5 is connected to one The water pumping hole 3 (top grouting hole) is then connected to the outer wall of the bucket through the one-way valve 7 and extends downwards along the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com