Double-accuracy filter

A filter, double-precision technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of system failure, large filter volume, insufficient oil supply, etc. Simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

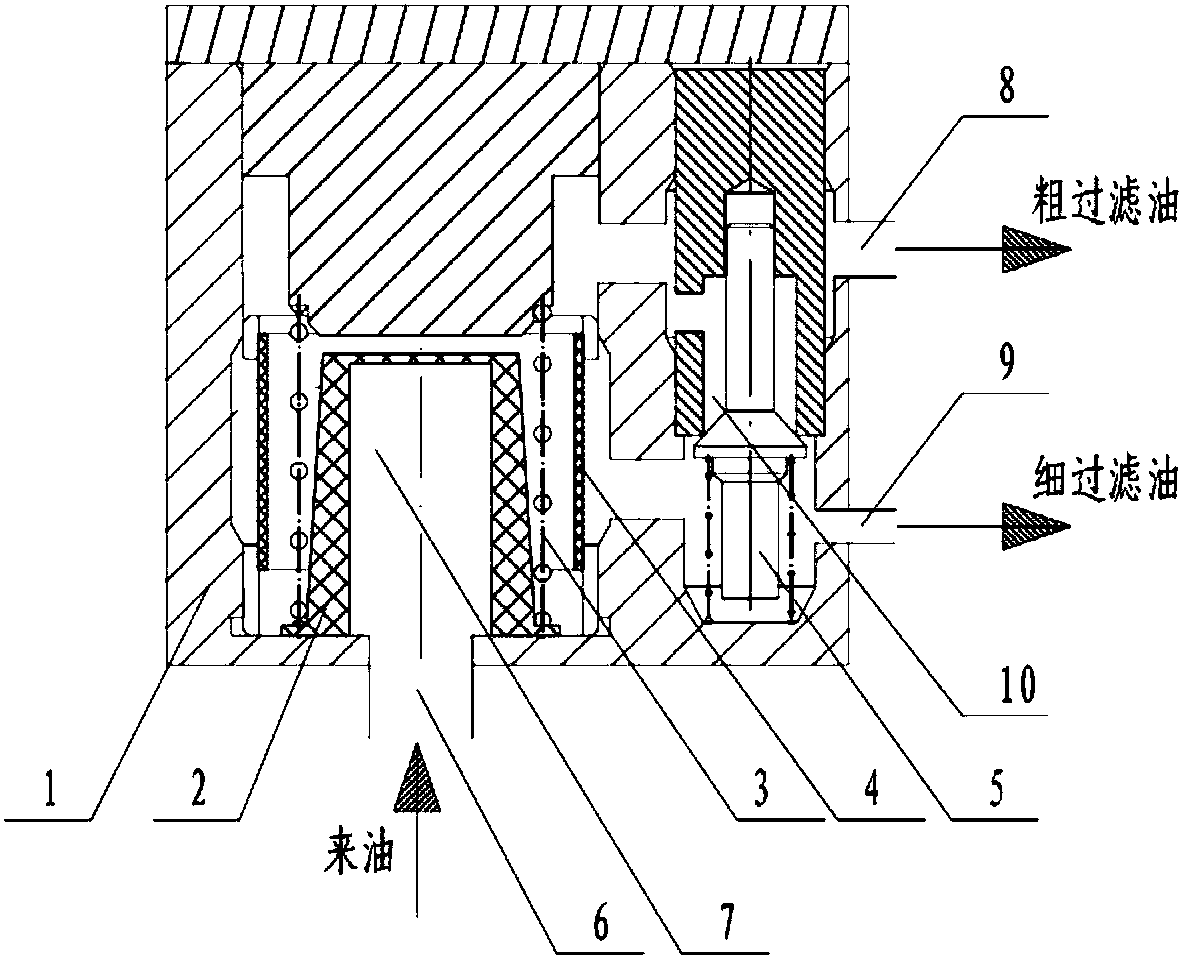

[0015] The present invention is a double-precision filter with a bypass function, including a housing 1, a coarse filter element 2, a coarse filter element pressure spring 3, a fine filter element 4, and a one-way valve 5;

[0016] The casing is provided with an oil inlet 6, a filter cavity 7, a first oil outlet channel 8, a second oil outlet channel 9 and a third oil outlet channel 10;

[0017] The coarse filter element and the compression spring of the coarse filter element are arranged in the filter cavity, and the compression spring of the coarse filter element elastically presses the coarse filter element on the oil inlet, so that the oil enters the filter cavity after passing through the coarse filter element;

[0018] The first oil outlet passage, the second oil outlet passage and the third oil outlet passage are all in communication with the filter chamber for leading the oil out of the filter chamber; the one-way valve is arranged in the third oil outlet passage, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com