A connection method for kitchen and bathroom multifunctional drainage pipelines without dead ends

A technology for drainage pipelines and connection methods, which is applied in the direction of branch pipelines, sealing surface connections, indoor sanitary pipeline installations, etc., to achieve the effects of preventing water flow from overturning, short connection ports, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

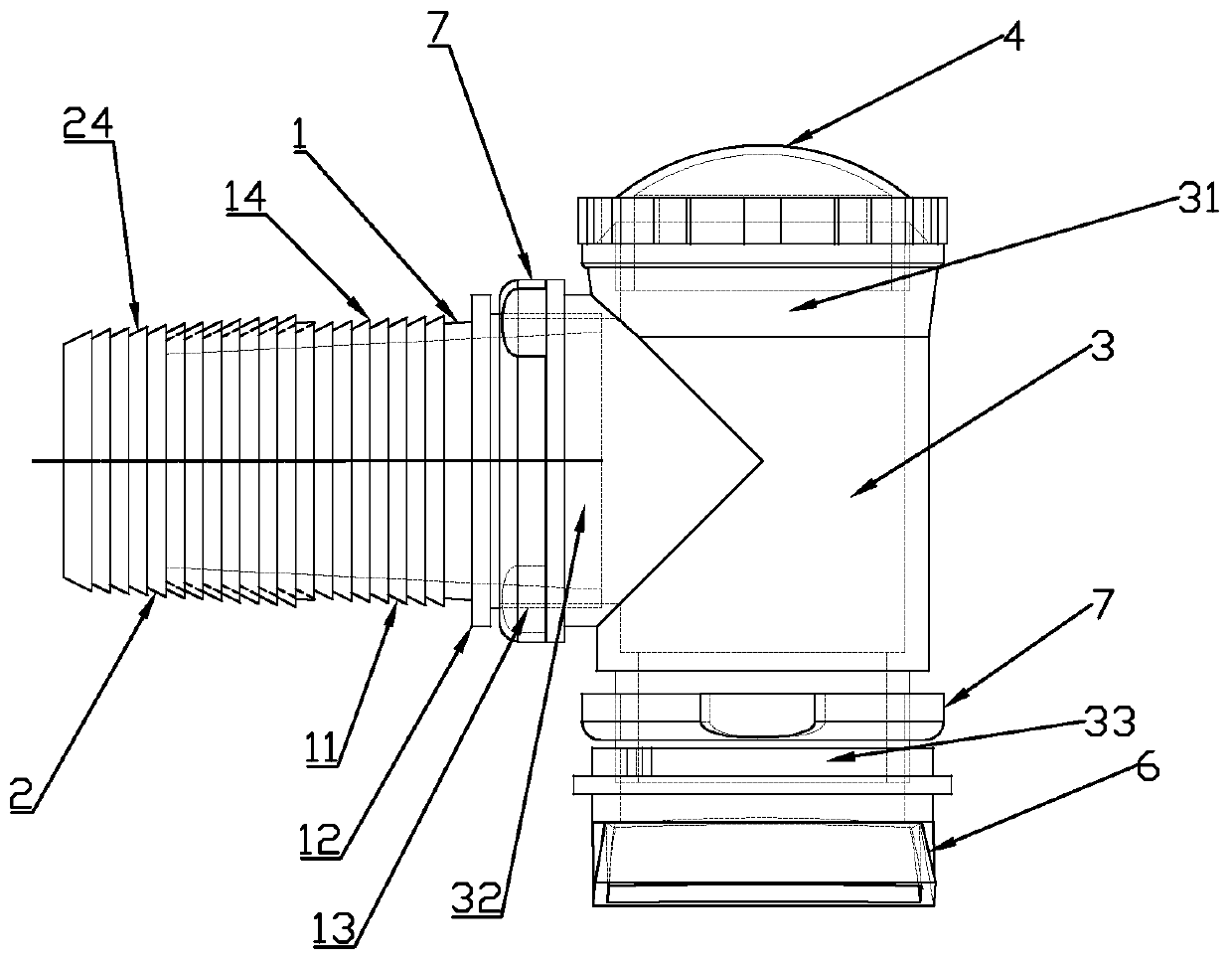

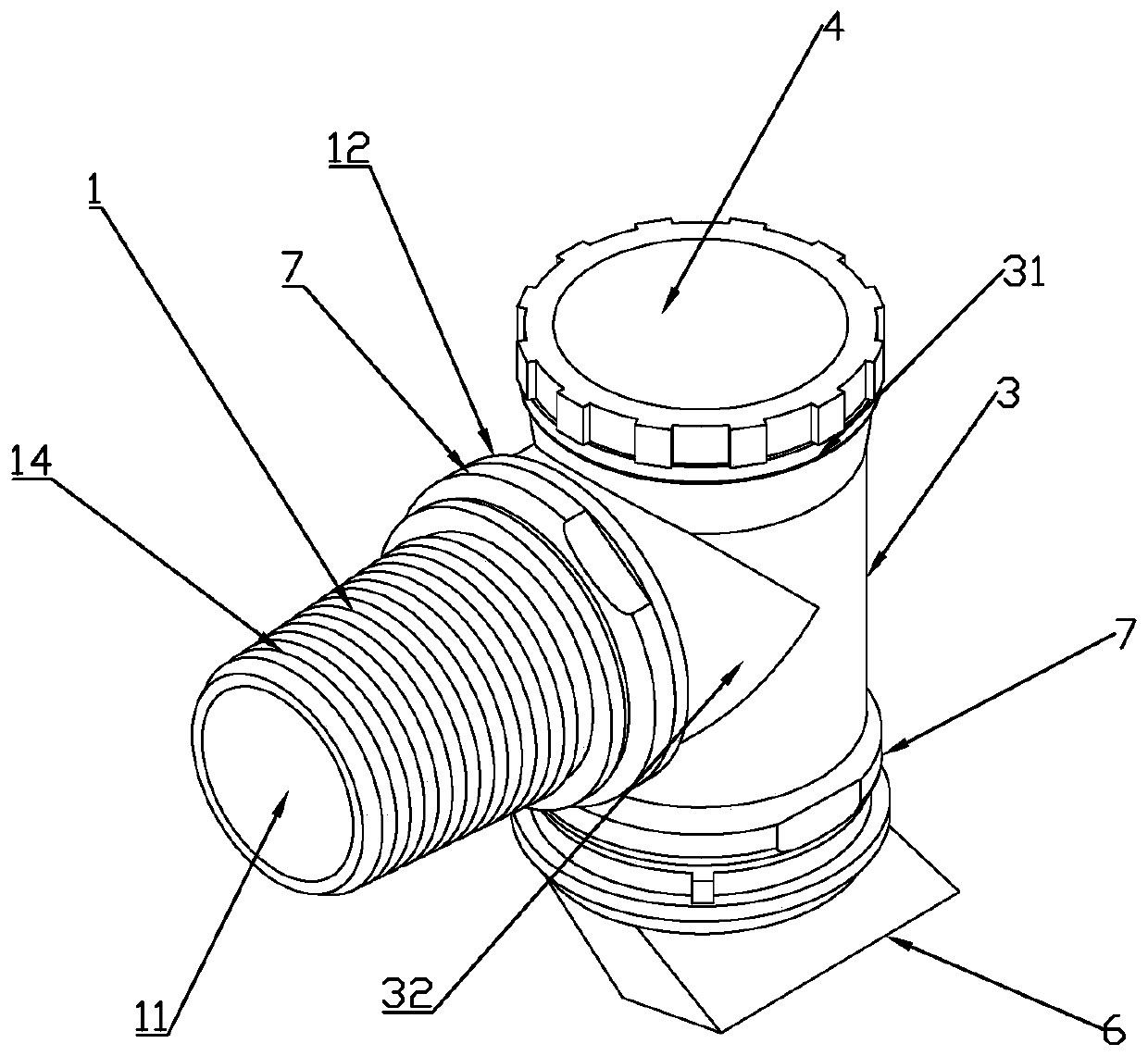

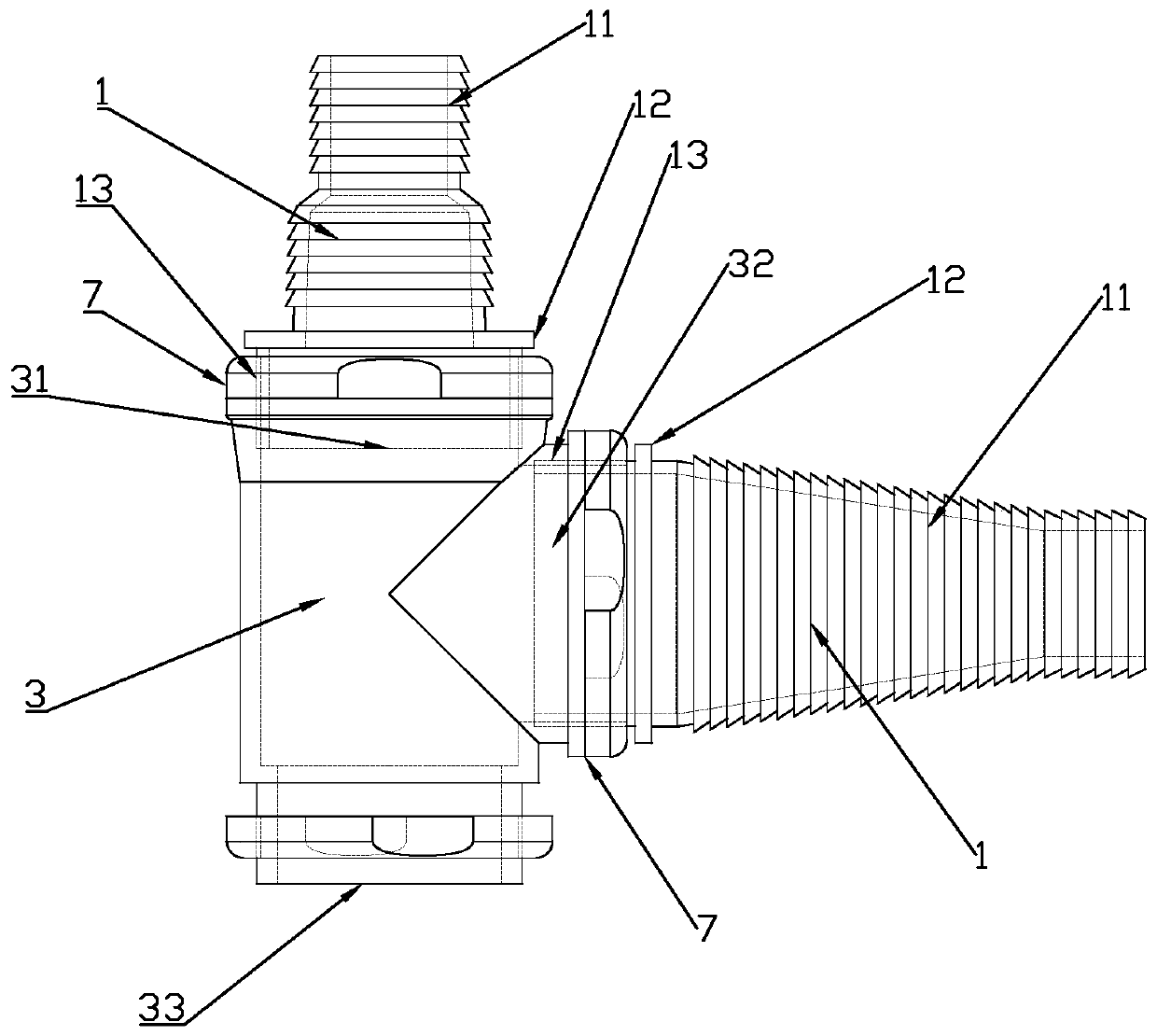

[0047] Such as Figure 1 to Figure 15 As shown, a method for connecting multifunctional drainage pipelines without dead ends for kitchens and bathrooms includes the following steps: S1: Connect the water outlet connection port at the bottom end of the three-way cylindrical shell 3 with the external drainage equipment through the directional drainage member 6;

[0048] S2: Connect the side connection port on the side of the three-way cylindrical shell 3 with the drain pipe connector 1 or other said three-way cylindrical shell 3;

[0049] S3: Connect the top connection port at the top of the three-way cylindrical shell 3 with the drainpipe connector 1 or other three-way cylindrical shells 3 .

[0050] Further, in the above technical solution, the S2 step includes:

[0051] S21: When the side connection port on the side of the three-way cylindrical shell 3 is connected to the drain pipe connector 1, the drain port of the drainage device is connected to the drain pipe connector 1...

Embodiment 2

[0066] Such as Figure 14 with Figure 15 As shown, the difference between this embodiment and Embodiment 1 is that the drainage pipe connector 1 includes a downpipe deodorant connection assembly, and the downwater pipe deodorization connection assembly includes a three-way connection ring 8 and a stepped connector 9. The three-way connection ring 8 sequentially includes an inner connection cylinder part 81, a middle connection ring part 82 and a curved outer stop ring part 83 from inside to outside, and the stepped connector 9 sequentially includes an end ring part 91, a middle step The ring portion and the lower stepped ring portion, the inner side wall of the middle stepped ring portion and the outer side wall of the middle connecting ring portion 82 are connected with each other.

[0067] Further, in the above technical solution, internal threads are provided on the inner side of the middle connecting ring part 82, and the inner side of the middle connecting ring part 82 ...

Embodiment 3

[0069] Such as figure 1 , figure 2 , Figure 12 with Figure 13 As shown, a method for connecting kitchen and bathroom multifunctional drainage pipelines without dead ends, including: a three-way cylindrical shell 3, a variable diameter rubber ring 2 and a drain pipe connector 1, the top end of the three-way cylindrical shell 3, Connecting ports are respectively provided on the side and the bottom end, the drain pipe connector 1 is in sealing connection with the connecting port of the three-way cylindrical shell 3, and the variable diameter rubber ring 2 is placed on the drain pipe connector 1;

[0070] The drainpipe connector 1 includes a drainpipe connecting part 11, a drainpipe stopper 12 and a three-way connecting part 13 from top to bottom, and the cavity in the variable-diameter rubber ring 2 includes a first The connection cavity 21 , the transition cavity 22 and the second connection cavity 23 , the diameter of the second connection cavity 23 is smaller than the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com