Airborne camera structure

A technology of camera and camera components, which is applied in the direction of image communication, TV, color TV components, etc., can solve the problems of not being able to meet the requirements of environmental adaptability, etc., and achieve the improvement of product quality and economic benefits, light weight and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

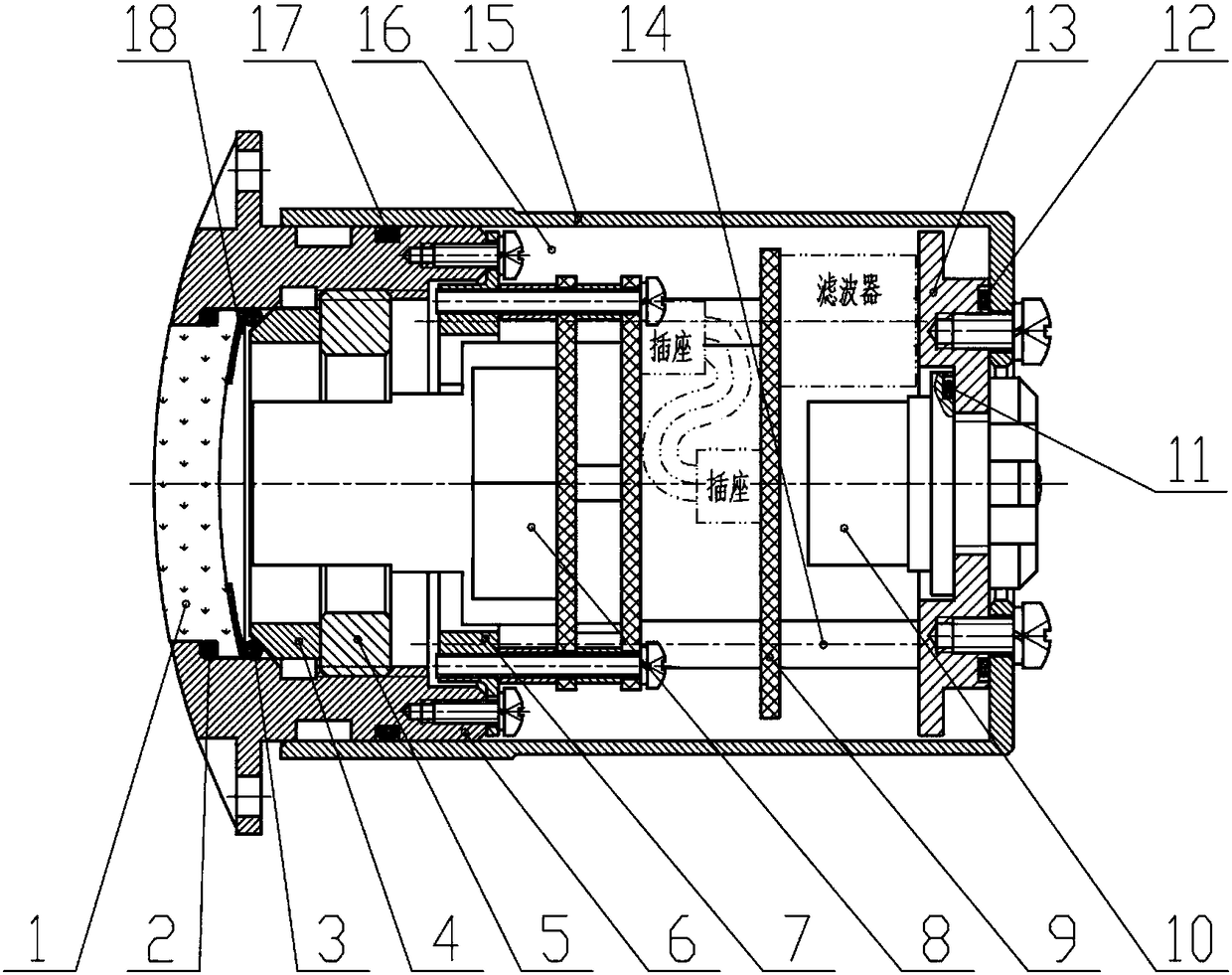

[0025] Example figure 1 As shown, an airborne camera structure includes: lens protection screen 1, lens protection screen front end seal ring 2, lens protection screen rear end seal ring 3, bushing ring 4, compression nut 5, front cover 6, camera assembly fixing Frame 7, camera assembly 8, function board 9, sealed connector 10, sealed connector seal ring 11, rear cover seal ring 12, rear cover 13, column 14, casing 15, nitrogen gas 16, front cover seal ring 17, heating Membrane module 18.

[0026] Described lens protective screen 1 is spherical shape, is fixed on front cover 6 front opening by lens protective screen front end sealing ring 2, lens protective screen rear end sealing ring 3, is pressed and fixed by lining ring 4, compression nut 5.

[0027] The camera assembly 8 is fixed on the camera assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com