Stocker with large storage space for raising pigs

A technology with a large space and a feeder, applied in applications, animal feeding devices, animal husbandry, etc., can solve problems such as unfavorable feed emptying treatment, increase in volume of agitating devices, and inability to move up and down, so as to increase feeding costs, Simple structure and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

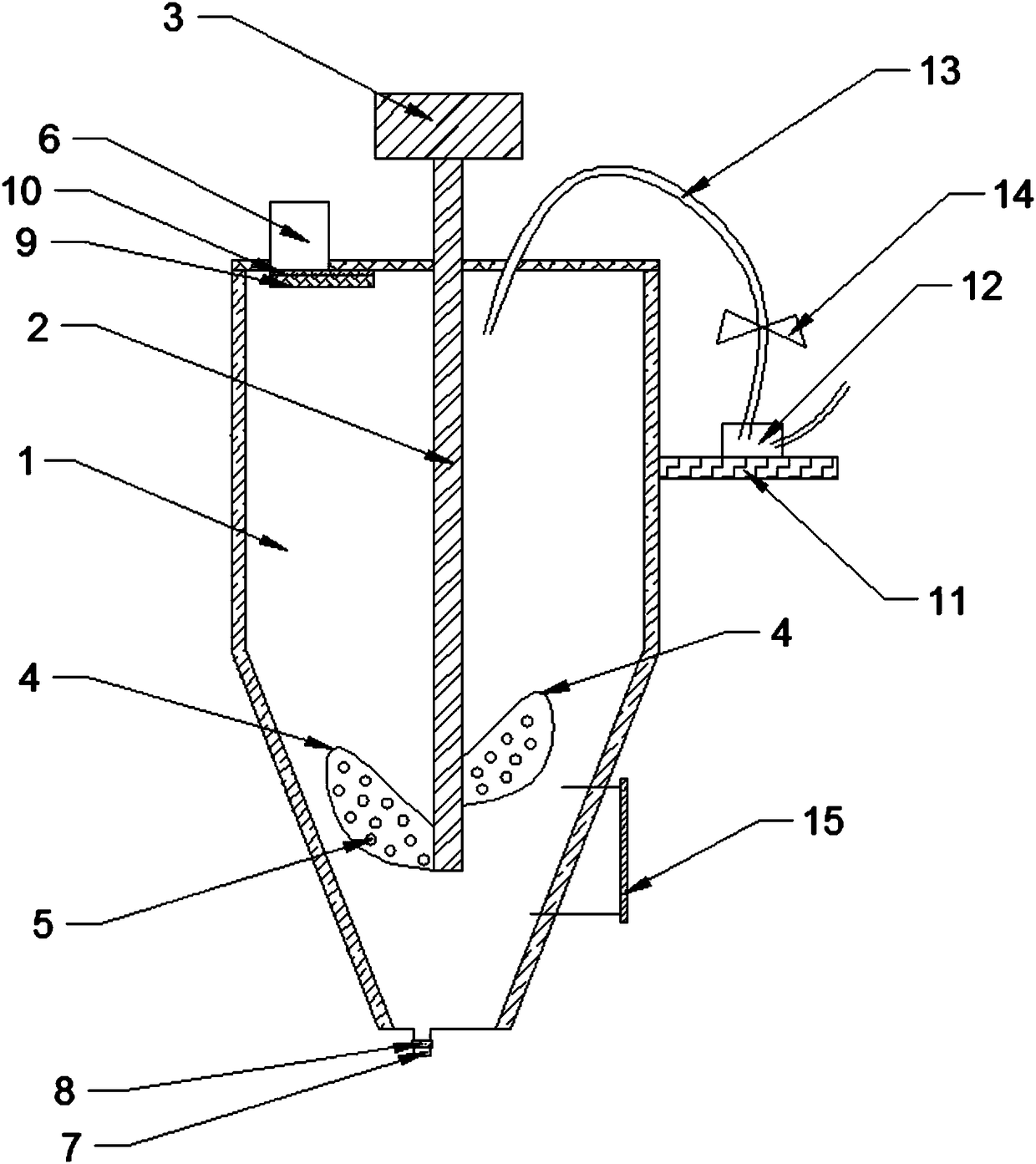

[0019] The technical solution of this embodiment is: a stocker for raising pigs with a large storage space, including a storage room 1, a through hole is opened on the storage room 1, a stirring rod 2 is arranged through the through hole, and a stirring rod 2 is arranged in the through hole. internal thread, the outer surface of the stirring rod 2 is provided with an external thread that cooperates with the internal thread, and one end of the stirring rod 2 protruding from the storage chamber 1 is connected with a reciprocating motor 3 that drives the stirring rod 2 to rotate around its own axis, stirring The lower end of the rod 2 is provided with two stirring blades 4, and each stirring blade 4 is provided with a number of ventilation holes 5;

[0020] The upper end surface of the storage chamber 1 is provided with a feed inlet 6, the bottom side wall of the feed inlet 6 is hinged with a cover plate 9, and the upper end surface of the cover plate 9 is bonded with a gasket 10;...

Embodiment 2

[0023] On the basis of Embodiment 1, the technical solution of this embodiment is: a mounting plate 11 is provided on the outer surface of the storage chamber 1, a nitrogen gas preparation device 12 is fixedly connected to the mounting plate 11, and the gas outlet of the nitrogen gas preparation device 12 is It communicates with the storage chamber 1 through a hose 13 , and a regulating valve 14 is arranged on the hose 13 .

[0024] Such as figure 1 As shown, when there is no need for feeding, start the nitrogen preparation device 12 and open the regulating valve 14 and adjust to a suitable opening as required, nitrogen enters the storage chamber 1 through the hose 13 so that the pressure in the storage chamber 1 increases and dilutes The air in the storage room 1, the air in the storage room 1 is diluted to avoid certain ingredients in the feed being oxidized for a long time in an environment with high oxygen content and lose their effect, which is not conducive to the growth...

Embodiment 3

[0026] Based on the first embodiment, the technical solution of this embodiment is: two stirring blades 4 are arranged alternately along the length direction of the stirring rod 2 .

[0027] Such as figure 1 As shown, the degree of turning over of the feed is increased, which is beneficial to fully mixing the feed that needs to be mixed, so that the nutritional components of the feed consumed by the pigs are uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com