Preparation method of soft sauce material and preparation method of double-colored mixed soft sauce by using preparation method of soft sauce material

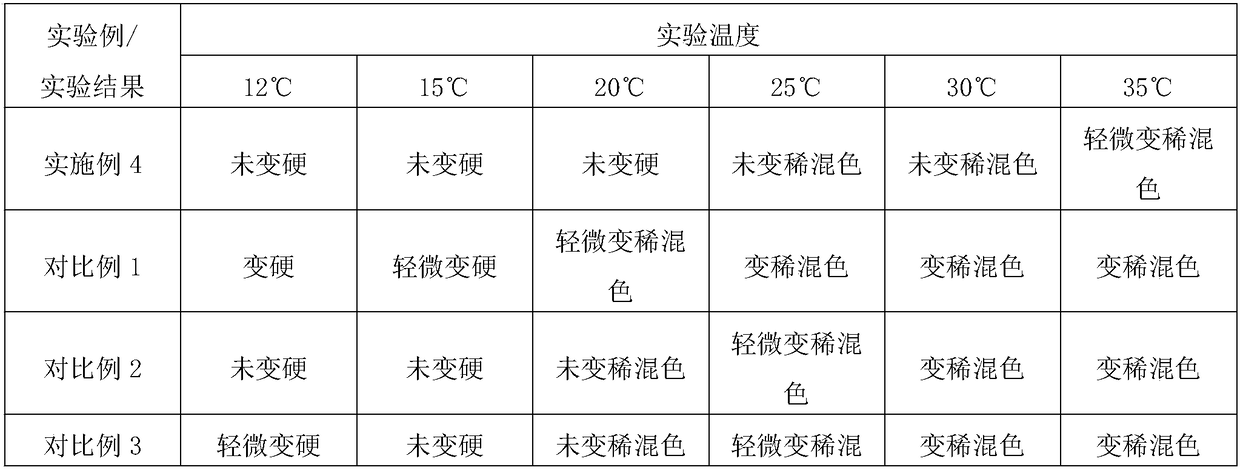

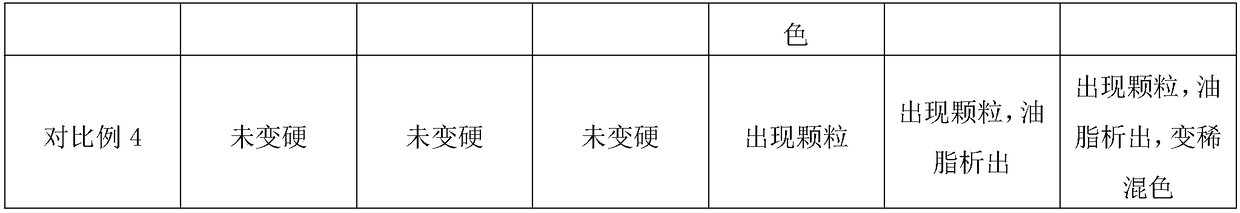

A color mixing and sauce technology, which is applied in food science and other fields, can solve the problems of oil separation, thinning and color mixing, hardening of sauce, etc., and achieve the effect of improving high temperature tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1: In parts by weight, mix 25-35 parts of white sugar, 15-25 parts of milk powder, and 30-45 parts of palm oil, and heat up the mixture to 40-45°C and mix evenly;

[0028] S2: Heat 2-5 parts by weight of glyceryl monostearate to above 60°C until fully melted, add to the mixture obtained in step S1, and then fully mix;

[0029] S3: Grinding the material mixed in step S2 to a particle size of 20-30 microns at 40-45°C with heat preservation cycle;

[0030] S4: The above-ground sauce is tempered in two stages in turn; the first stage is tempered to the sauce temperature of 40-41°C, and the temperature is kept stirring for 120-240min during the tempering process; the second stage is tempered to the sauce temperature of 37- Stir at 38°C for 60-120 minutes to obtain the first soft sauce;

[0031] S5: In parts by weight, mix 6-10 parts of cocoa powder, 25-35 parts of white sugar, 15-25 parts of milk powder and 30-45 parts of palm oil, and heat up the mixture to 40-45°C and mi...

Embodiment 2

[0038] S1: In parts by weight, mix 25 parts of white sugar, 15 parts of milk powder, and 30 parts of palm oil, and heat up the mixture to 45°C and mix evenly;

[0039] S2: Heat 3 parts by weight of glyceryl monostearate to 60-65°C until fully melted, add it to the mixture obtained in step S1, and then fully mix;

[0040] S3: Grinding the material mixed in step S2 to a particle size of 20-30 microns at 40-45°C with heat preservation cycle;

[0041] S4: The above-ground sauce is tempered in two stages in turn; the first stage is tempered to the temperature of the sauce at 40-41°C, and kept stirring for 150 minutes during the tempering process; the second stage is tempered to the sauce at 37-38°C temperature, and stirred for 90 minutes to obtain the first soft sauce;

[0042] S5: In parts by weight, mix 6 parts of cocoa powder, 25 parts of white sugar, 15 parts of milk powder and 30 parts of palm oil, and heat up the mixture to 40-45°C and mix evenly;

[0043] S6: Heat 3 parts ...

Embodiment 3

[0049] S1: In parts by weight, mix 35 parts of white sugar, 25 parts of milk powder, and 45 parts of palm oil, and heat up the mixture to 45°C and mix evenly;

[0050] S2: Heat 3 parts by weight of mono- and diglycerides to 60-65°C until fully melted, add to the mixture obtained in step S1, and then fully mix;

[0051] S3: Grinding the material mixed in step S2 to a particle size of 20-30 microns at 40-45°C with heat preservation cycle;

[0052] S4: The above-ground sauce is tempered in two stages in turn; the first stage is tempered to the temperature of the sauce at 40-41°C, and kept stirring for 200 minutes during the tempering process; the second stage is tempered to the sauce at 37-38°C temperature, and stirred for 120min to obtain the first soft sauce;

[0053]S5: In parts by weight, mix 10 parts of cocoa powder, 35 parts of white sugar, 25 parts of milk powder, and 45 parts of palm oil, and heat up the mixture to 40-45°C and mix evenly;

[0054] S6: heating 3 parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com