Laser crystallization device and method for controlling crystallization laser beam

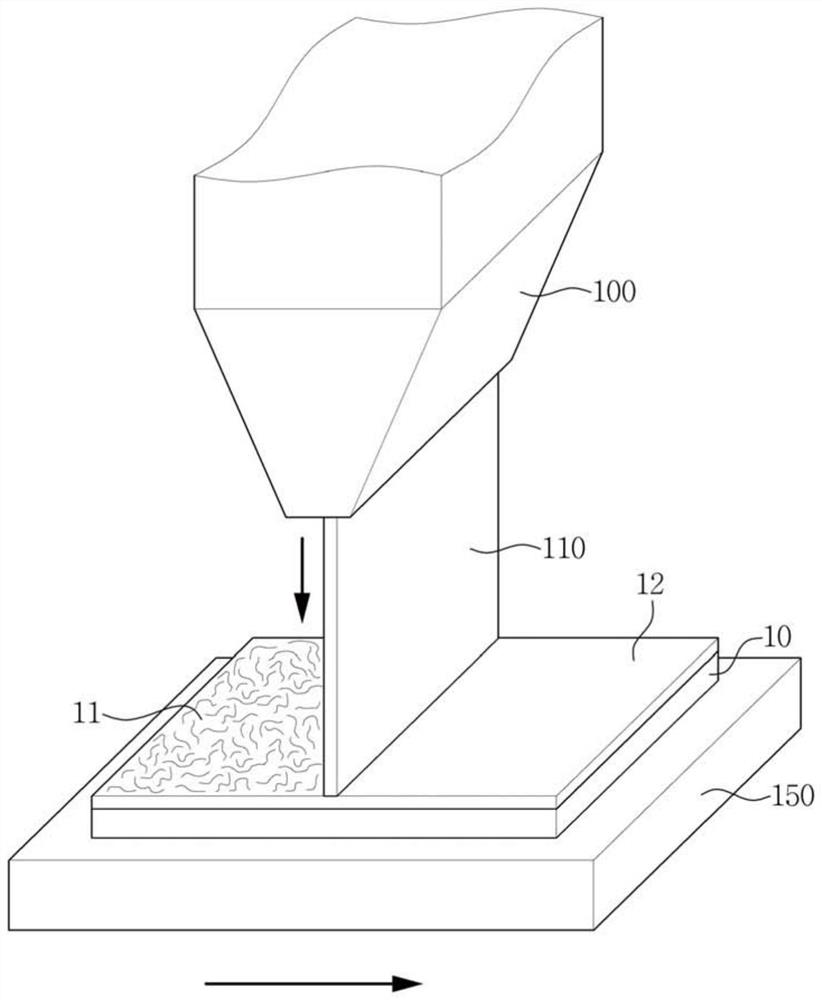

A laser crystallization and laser beam technology, applied in lasers, laser welding equipment, laser parts and other directions, can solve the problem of uneven crystallinity of amorphous silicon layer, and achieve the effect of improving crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

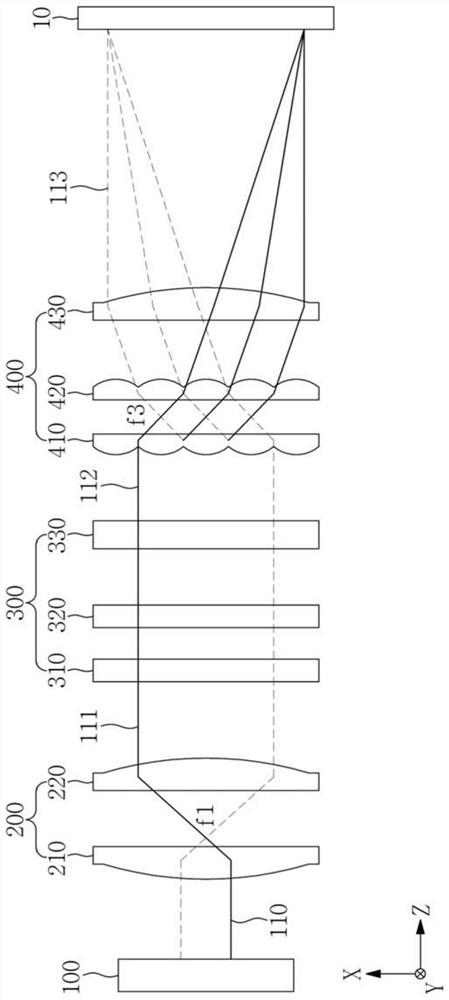

Method used

Image

Examples

Embodiment Construction

[0044] Advantages and features of the present invention, and methods for achieving them will become apparent when referring to the accompanying drawings and embodiments described in detail hereinafter. However, the present invention can be realized in different forms, and is not limited to the embodiments disclosed below, but the purpose of providing this embodiment is to make the disclosure of the present invention complete, and to give a basic understanding to the technical field to which the present invention belongs. It is provided for persons with knowledge to fully describe the scope of the invention, and the present invention is defined only by the scope required by the appended claims. Therefore, in various embodiments, in order to prevent the present invention from being ambiguously interpreted, well-known process steps, well-known element structures, and well-known technologies are not described in detail. Throughout the specification, the same reference numerals ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com