Method for preparing beta-BC2N nano-rod under temperate condition

A technology of nanorods and conditions, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as unfavorable production, expensive equipment or relatively harsh, and achieve low-cost synthesis, easy preparation scale, and product morphology Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under the protection of nitrogen in the glove box, 4.096 grams of analytically pure NaN 3 Add to 30ml of distilled anhydrous acetonitrile, stir for 20 minutes to make it evenly dispersed, then add 2ml of liquid BBr 3 , continue stirring for 5 minutes, transfer the mixture to a 50ml stainless steel reaction kettle, and seal it. Place the reaction kettle in a crucible boiler, heat it at 500°C for 24 hours, then allow the kettle to cool down to room temperature naturally, and take out the product. Wash with absolute ethanol and distilled water three times in sequence, filter, and then vacuum-dry at 80°C for 6 hours to obtain β-BC containing trace oxygen defects 2 N nanorods.

Embodiment 2

[0024] Under the protection of nitrogen in the glove box, 4.096 grams of analytically pure NaN 3 Add to 10ml of distilled anhydrous acetonitrile, stir for 10 minutes to disperse evenly, then add 2ml of liquid BBr 3 , continue to stir for 2 minutes, transfer the mixture to a 15ml stainless steel reaction kettle, and seal it. Place the reaction kettle in a crucible boiler, heat it at 480°C for 30 hours, then allow the kettle to cool down to room temperature naturally, and take out the product. Wash with absolute ethanol and distilled water three times in sequence, filter, and then vacuum-dry at 80°C for 6 hours to obtain β-BC containing trace oxygen defects 2 N nanorods.

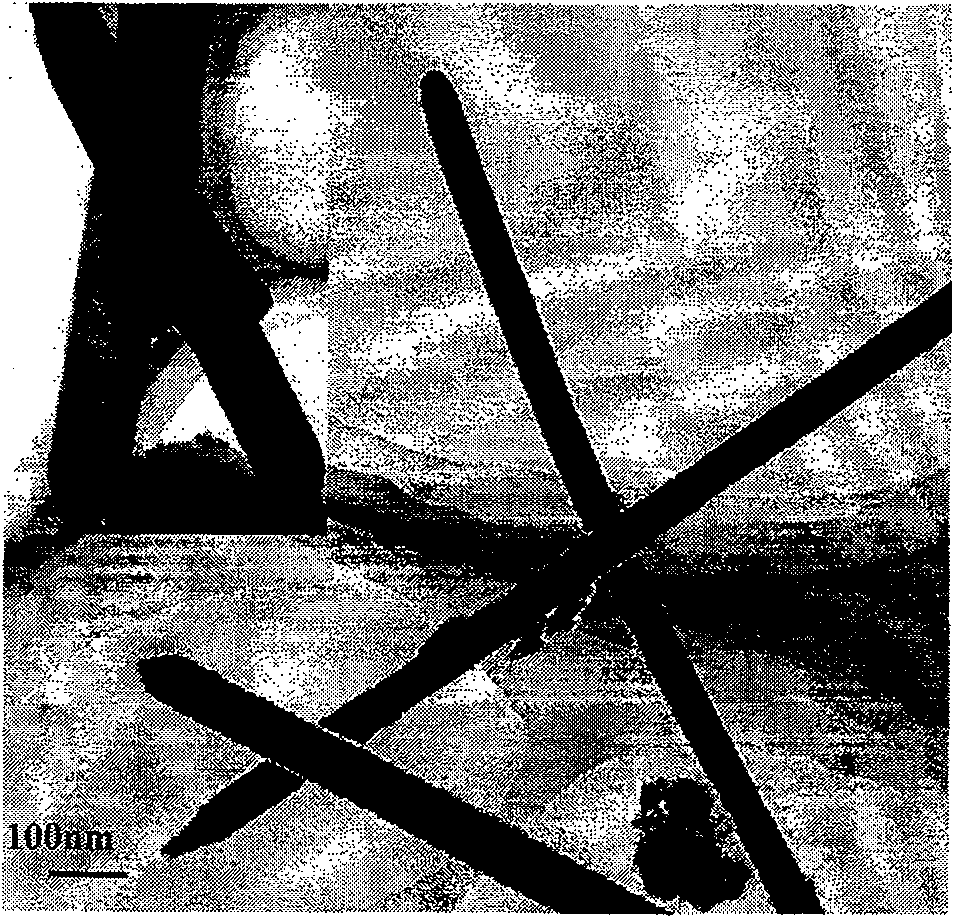

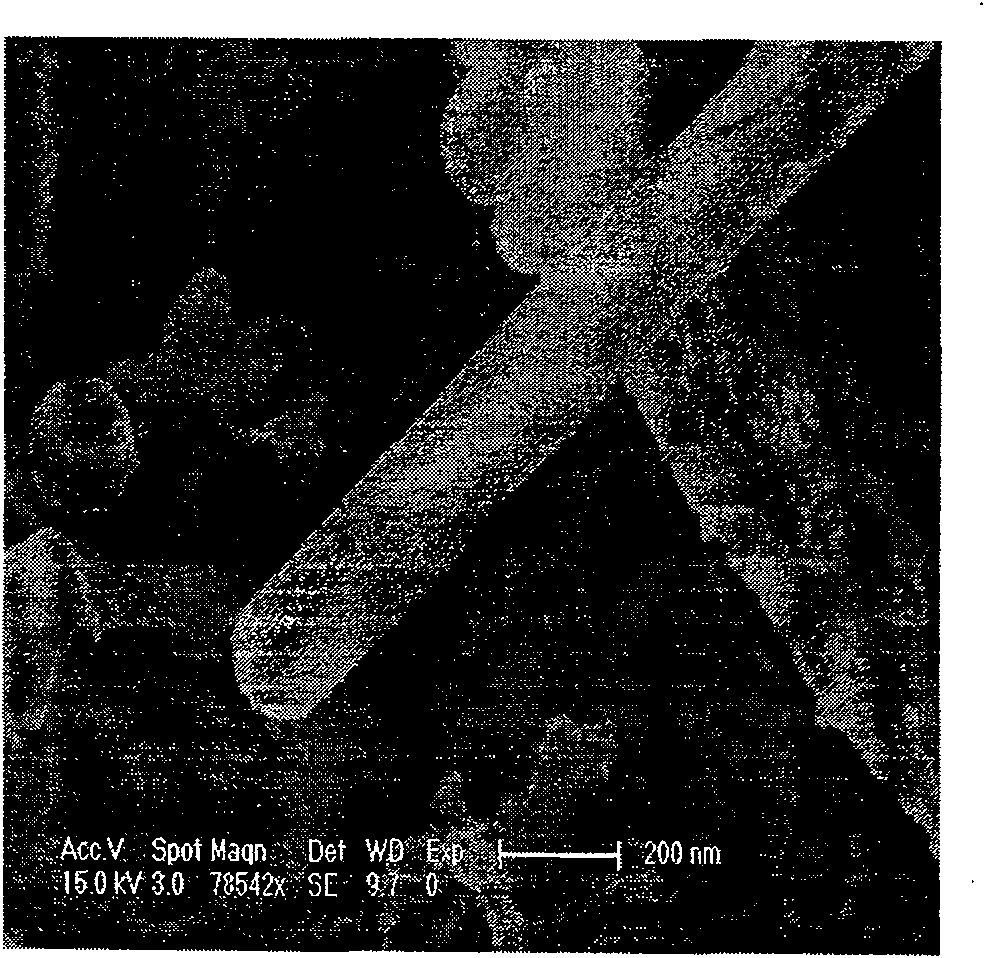

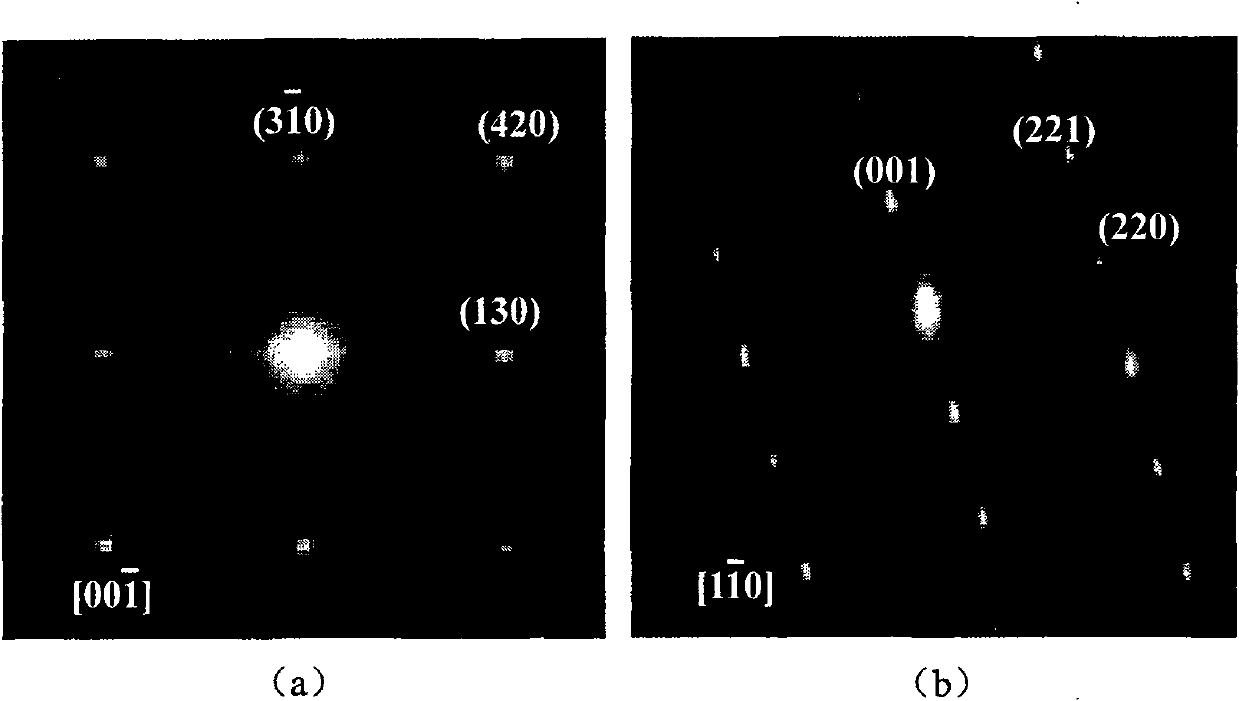

[0025] figure 1 and figure 2 Transmission and scanning electron microscope pictures of the as-prepared nanorods are given. It can be seen from the figure that all the nanorods are straight rods with a diameter ranging from 50 to 210 nm and a ratio of length to diameter of 5 to 30. The nanorods prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com