Nanometer iron rust conversion agent and preparation method thereof

A conversion agent and rust technology, applied in the coating process of metal materials, etc., can solve problems affecting the physical condition of workers and users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

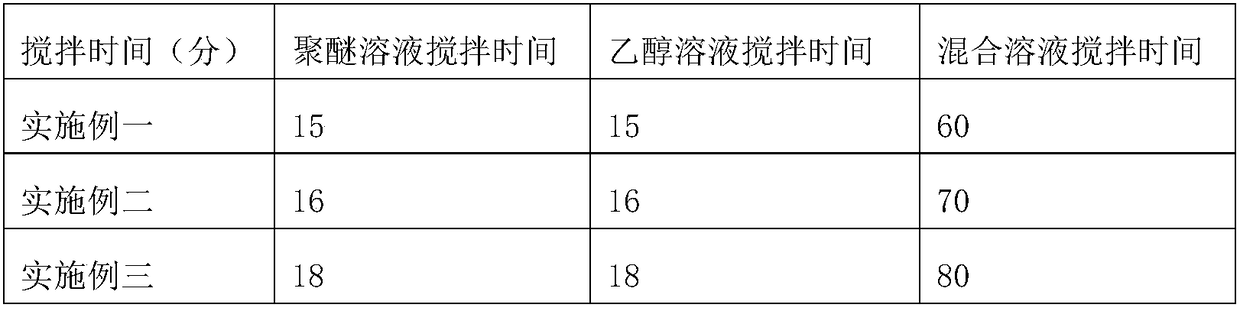

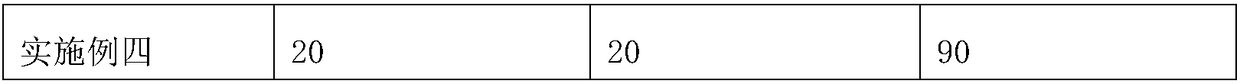

Examples

Embodiment Construction

[0014] A nano-rust conversion agent of the present invention, each component is calculated by weight, wherein 30-45 parts of ethanol, 1.5-3 parts of salicylic acid, 100-115 parts of polyether, 1.5-2.5 parts of quinic acid, nonionic 5-7 parts of surfactant, 3-4 parts of sodium petroleum sulfonate, 240-280 parts of water.

[0015] As a further improvement of the above-mentioned technical scheme: the nonionic surfactant is a polyoxyethylene type nonionic active agent, which is a surfactant that does not generate ions in an aqueous solution, and its penetration and detergency are very good. Well, the emulsifying power is also quite strong. The solubility of nonionic surfactants in water is due to the strong hydrophilic functional groups in the molecule. Nonionic surfactants are second only to anionic surfactants in quantity, and are an important type of large-scale use. Therefore, their materials is also more convenient,

[0016] By adopting the above technical scheme, the reage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com