High temperature resistant and high pressure resistant rotary compensator

A rotary compensator, high temperature resistant technology, applied in expansion compensation devices for pipelines, pipes/pipe joints/pipes, mechanical equipment, etc. performance, the effect of improving sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

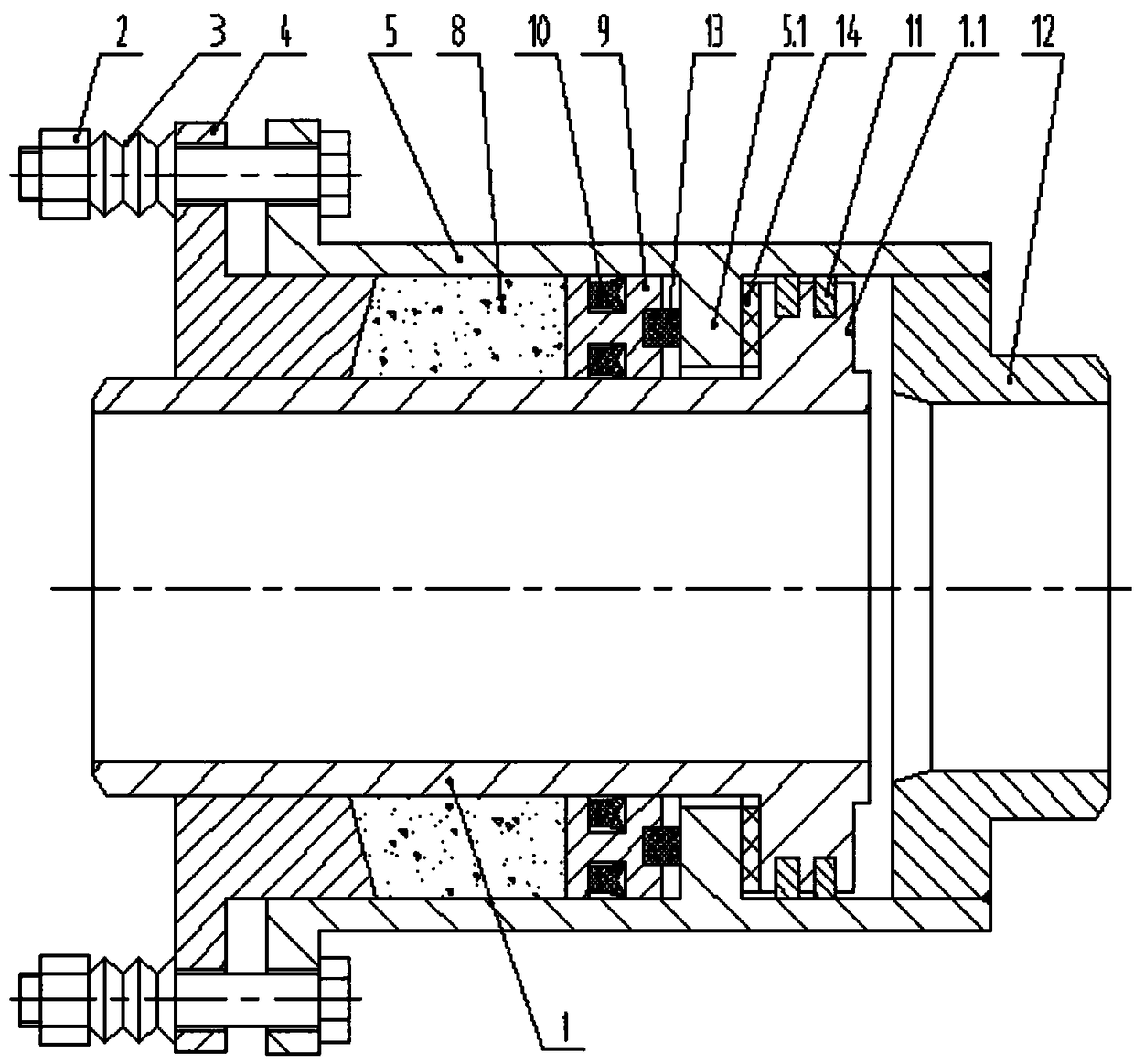

[0019] The high-temperature and high-pressure rotary compensator shown in the accompanying drawings includes a rotary inner tube 1, a bolt and nut assembly 2, an outer casing 5, a gland 4, graphite packing 8, a movable sealing ring 9 and a connecting tube 12; There is an outer shoulder 1.1; the middle part of the inner wall of the outer sleeve 5 is provided with an inner shoulder 5.1; the outer sleeve 5 fits on the rotating inner tube 1 from left to right; the connecting pipe 12 is fixedly connected to the right end of the outer sleeve 5; the gland 4 fits in a gap At the right end of the rotating inner tube 1, a flange is provided at its left end, and its right end extends into the right end hole of the outer tube 5, and forms a packing seal with the left end face of the inner shoulder 5.1 of the outer tube 5, the inner hole of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com