Coordinate measuring device comprising an optical sensor, and corresponding method

A coordinate measurement and sensor technology, applied in the field of optical measurement of gear workpieces, to achieve the effect of fast gear measurement and accurate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In the context of this description, terms that are also used in related publications and patents are used. However, it should be noted that these terms are used only to provide better understanding. The inventive concept and protection scope of the patent claims are not limited by the specific choice of terms. The invention can be readily applied to other conceptual systems and / or subject areas. In other subject areas, these terms will apply mutatis mutandis.

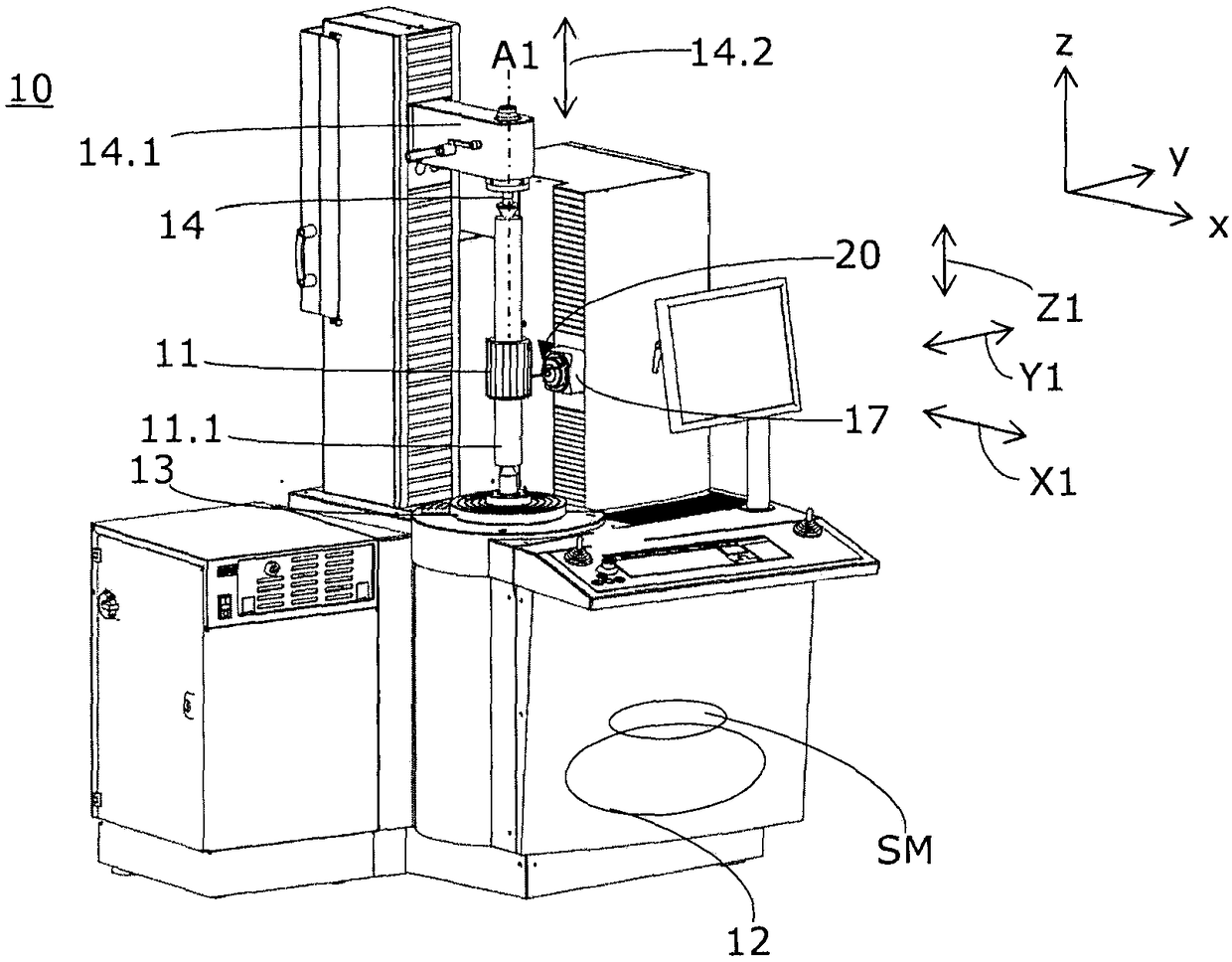

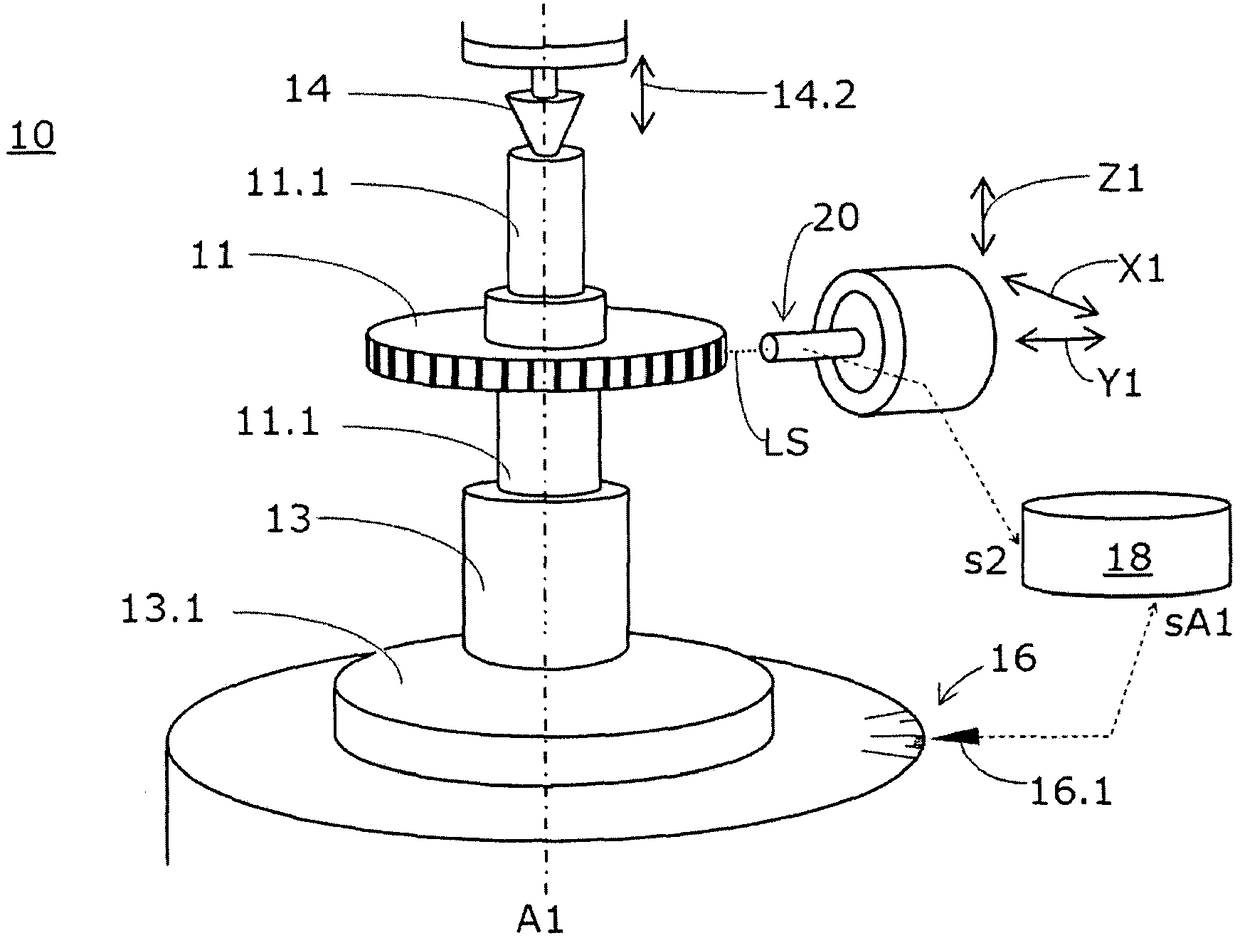

[0052] exist figure 1 An advantageous embodiment of the invention shown in , relates to an automated CNC-controlled gear measuring center 10 generally referred to herein as a coordinate measuring device 10 . The coordinate measuring device 10 is in principle suitable for checking general dimensional, shape and positional deviations on spur gear teeth as well as cutting and grinding wheels, worms and worm gears, hobs, bevel gears and rotationally symmetrical workpieces for bending and camshaft measurements or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com