Semiconductor device with metallization structure on opposite sides of a semiconductor portion

A metallized structure, semiconductor technology, applied in the fields of semiconductor/solid-state device parts, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of complex operation, complex operation and cutting of thin semiconductor die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

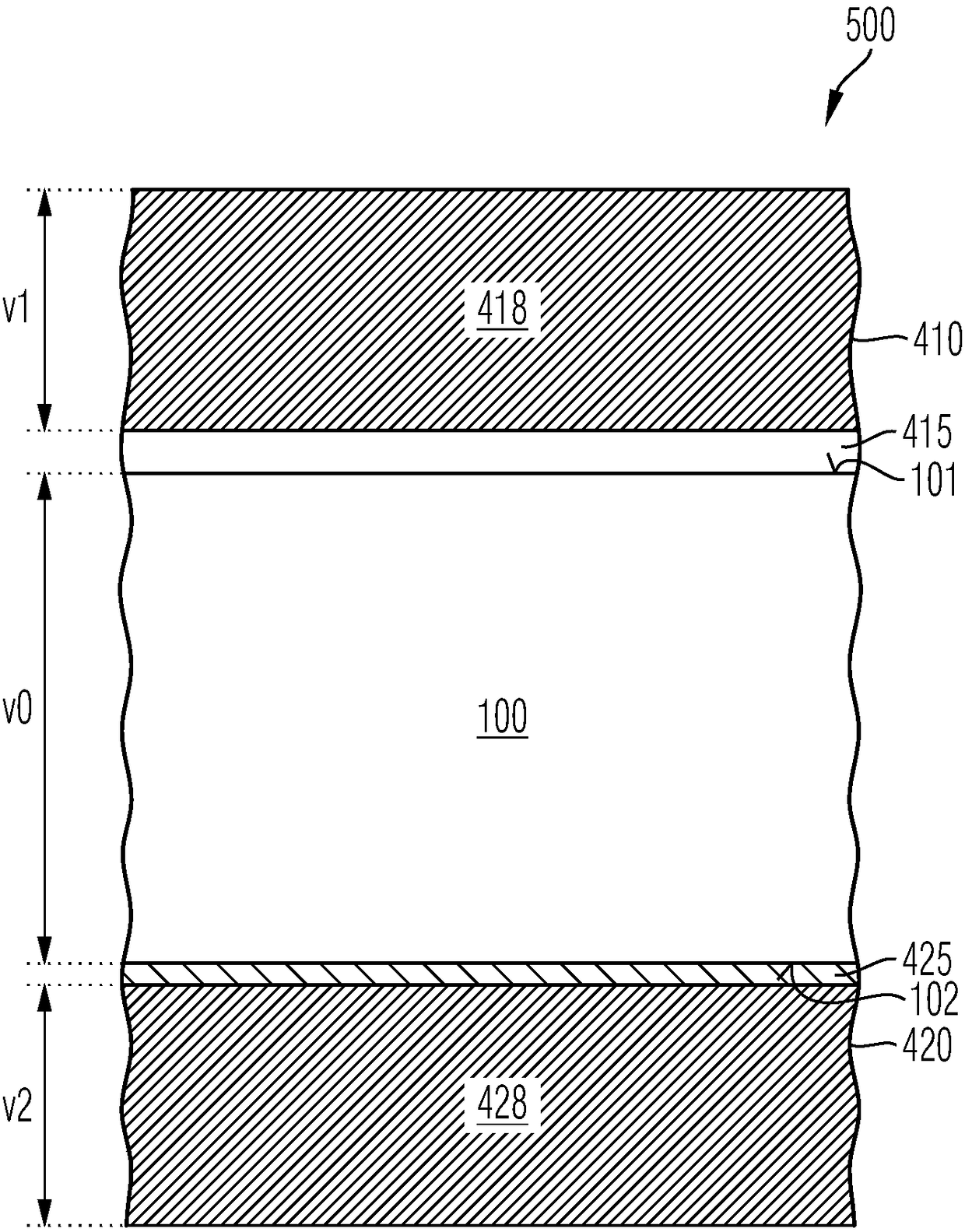

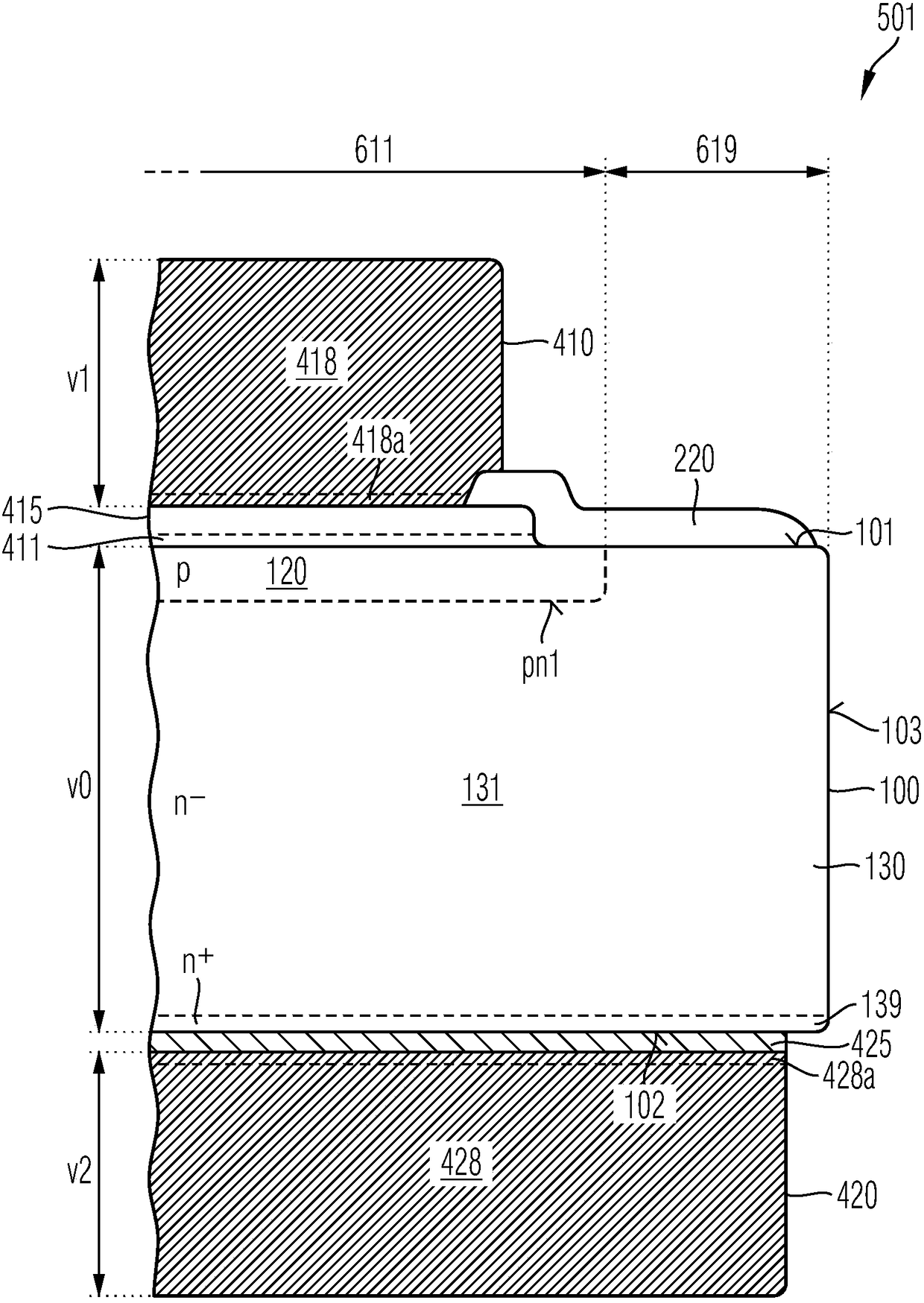

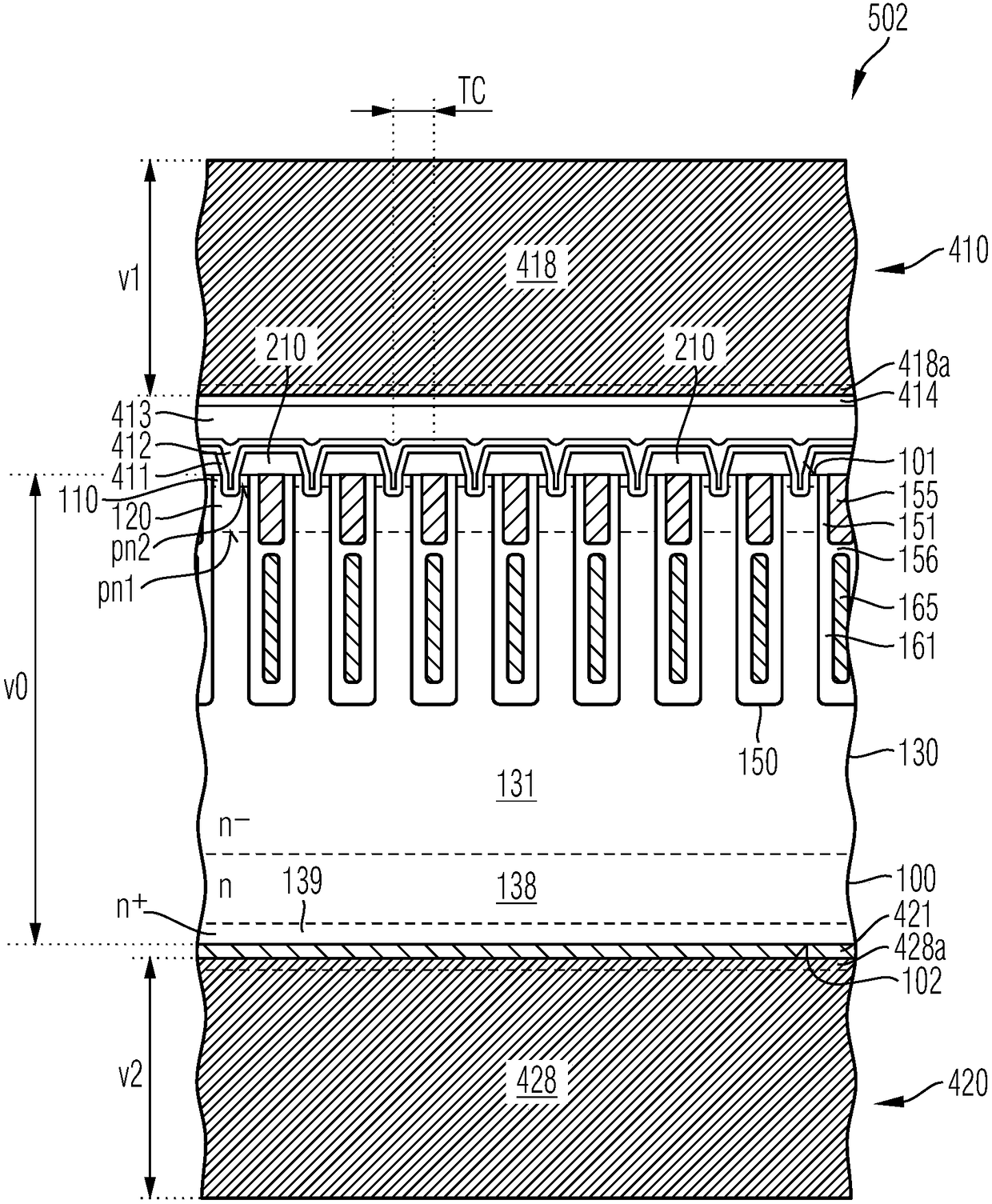

[0043] In the following detailed description, reference is made to the accompanying drawings, which form a part hereof, and in which are shown by way of illustrations specific embodiments in which the invention may be practiced. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention. For example, features illustrated or described with respect to one embodiment can be used on or in conjunction with other embodiments to yield a still further embodiment. It is intended that the present invention includes such modifications and variations. These examples were described in specific language, which should not be construed as limiting the scope of the appending claims. The drawings are not drawn to scale and are for illustrative purposes only. If not stated otherwise, corresponding elements are provided with the same reference numerals in the different figures.

[0044] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com