Graphene/metal composite material modified adhesive impregnated veneer and preparation method thereof

A metal composite material and nanocomposite material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of increasing the cost of resin preparation, unsuitable for mass production, expensive graphene, etc. Strong, no cracking or peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

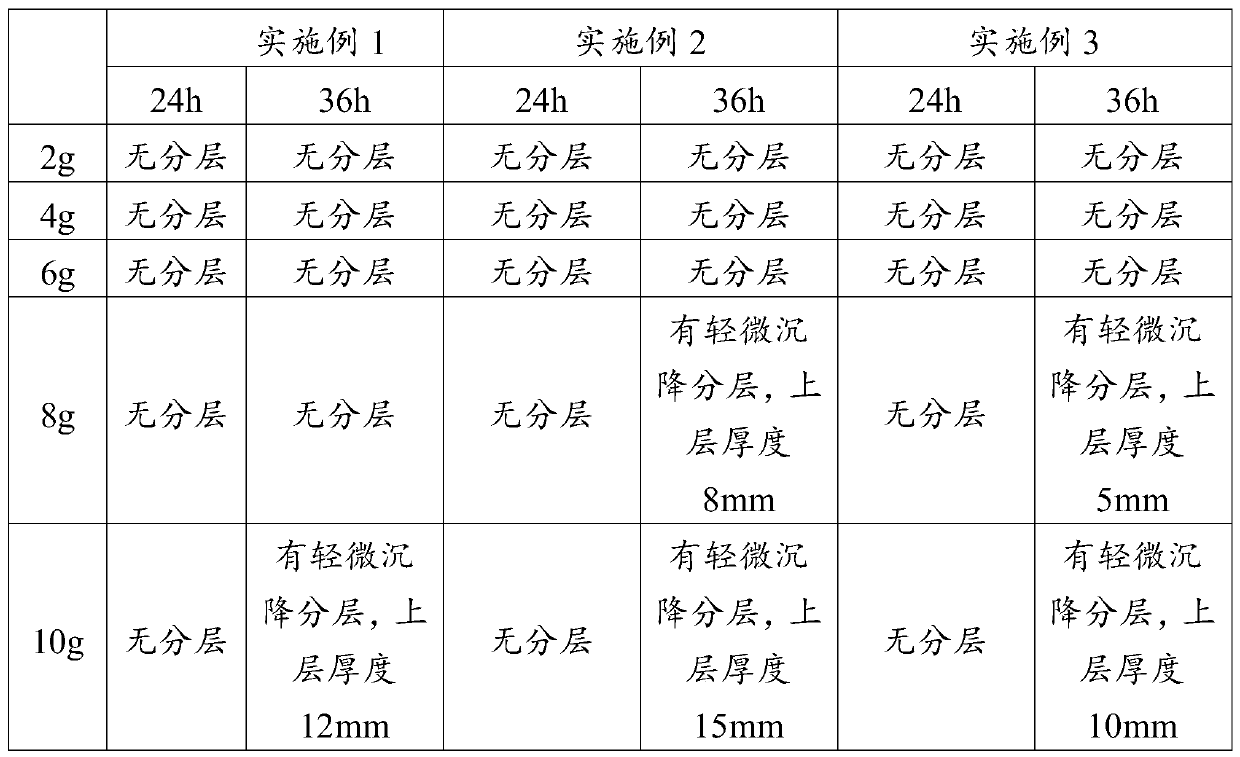

Embodiment 1

[0044] A highly thermally conductive graphene / metal composite material modified adhesive impregnated veneer, which is obtained by soaking a log veneer with a graphene / metal composite material modified adhesive and drying, the graphene / metal composite material modified The adhesive is composed of impregnated resin and ammonium polyphosphate-organic bentonite / graphene-Cu composite nanomaterial, and every 100 parts by weight of resin contains 3 parts by weight of ammonium polyphosphate-organic bentonite / graphene-Cu composite nanomaterial, which The preparation method is as follows:

[0045] 1) Graphene is mixed with Cu, carried out ultrafine and nano-grinding, the mixture is put into the mixed solution of ethylene glycol and ethylene, and the suspension of graphene / Cu is obtained by catalysis of ethylene glycol, and the precipitation is filtered for many times, finally at 60 ℃ drying to obtain the graphene / Cu nanocomposite material;

[0046] 2) with step 1) graphene / Cu nanocompo...

Embodiment 2

[0064] A highly thermally conductive graphene / metal composite material modified adhesive impregnated veneer, which is obtained by soaking a log veneer with a graphene / metal composite material modified adhesive and drying, the graphene / metal composite material modified The adhesive is composed of impregnated resin and ammonium polyphosphate-organic bentonite / graphene-Cu composite nanomaterial, and 8 parts by weight of ammonium polyphosphate-organic bentonite / graphene-Cu composite nanomaterial is contained in every 100 parts by weight of resin. The preparation method is as follows:

[0065] 1) Graphene is mixed with Cu, subjected to ultra-fine and nano-pulverization, the mixture is put into a solution mixed with ethylene glycol and ethylene, and graphene / C is prepared by catalyzing ethylene glycol. U The suspension was filtered and precipitated several times, and finally dried at 70°C to obtain a graphene / Cu nanocomposite material;

[0066] 2) with step 1) graphene / Cu nanocompo...

Embodiment 3

[0084] A highly thermally conductive graphene / metal composite material modified adhesive impregnated veneer, which is obtained by soaking a log veneer with a graphene / metal composite material modified adhesive and drying, the graphene / metal composite material modified The adhesive is composed of impregnated resin and ammonium polyphosphate-organic bentonite / graphene-Cu composite nanomaterial, and every 100 parts by weight of resin contains 5 parts by weight of ammonium polyphosphate-organic bentonite / graphene-Cu composite nanomaterial, which The preparation method is as follows:

[0085] 1) Graphene is mixed with Cu, subjected to ultra-fine and nano-pulverization, the mixture is put into a solution mixed with ethylene glycol and ethylene, and graphene / C is prepared by catalyzing ethylene glycol. U The suspension was filtered and precipitated several times, and finally dried at 65°C to obtain a graphene / Cu nanocomposite material;

[0086] 2) with step 1) graphene / Cu nanocompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com