Installation tool for cable insulation cable cleat

A technology for puncturing wire clips and cable insulation, which is applied to contact members with insulating cutting edges, needle tip/slotted plate contacts used to penetrate insulated wires/cable core wires, circuits, etc., which can solve the problem of insulation and sealing The rubber pads are not closely matched, the balance state is difficult to achieve, and the maintenance is unfavorable, so as to achieve good electrical contact effect, ensure stable and close contact, and improve the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

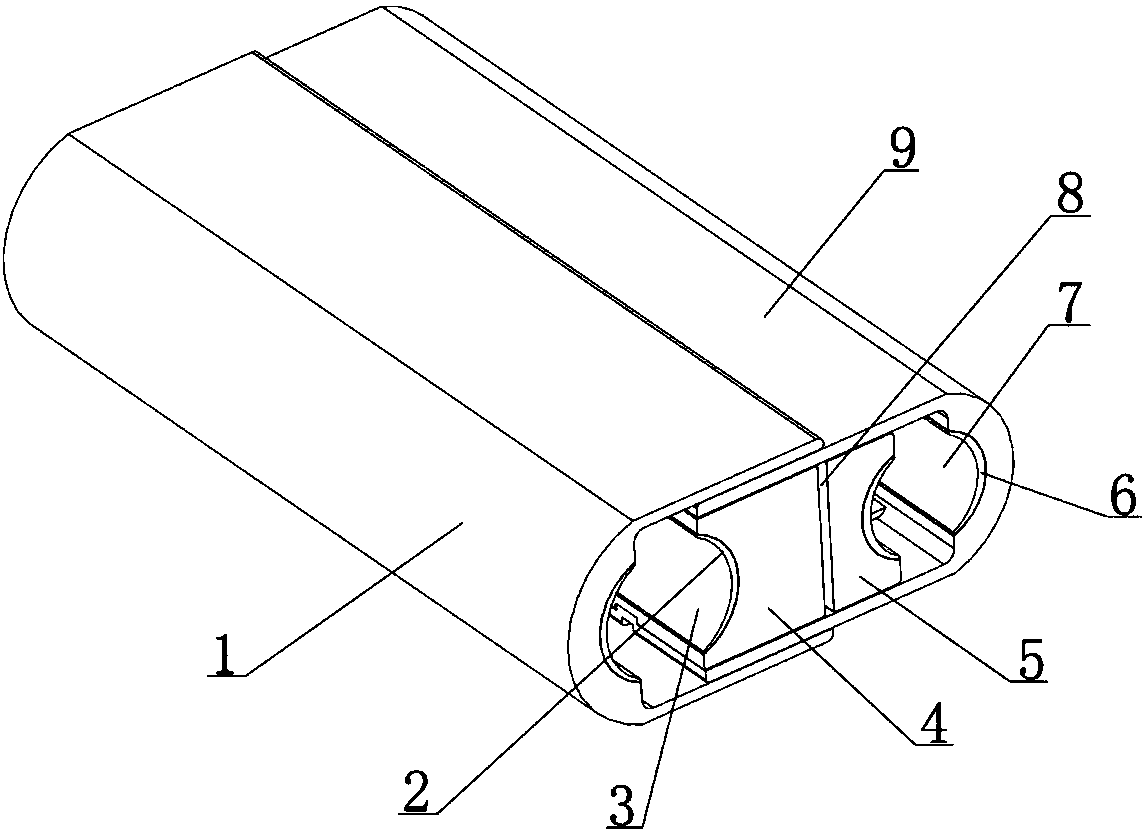

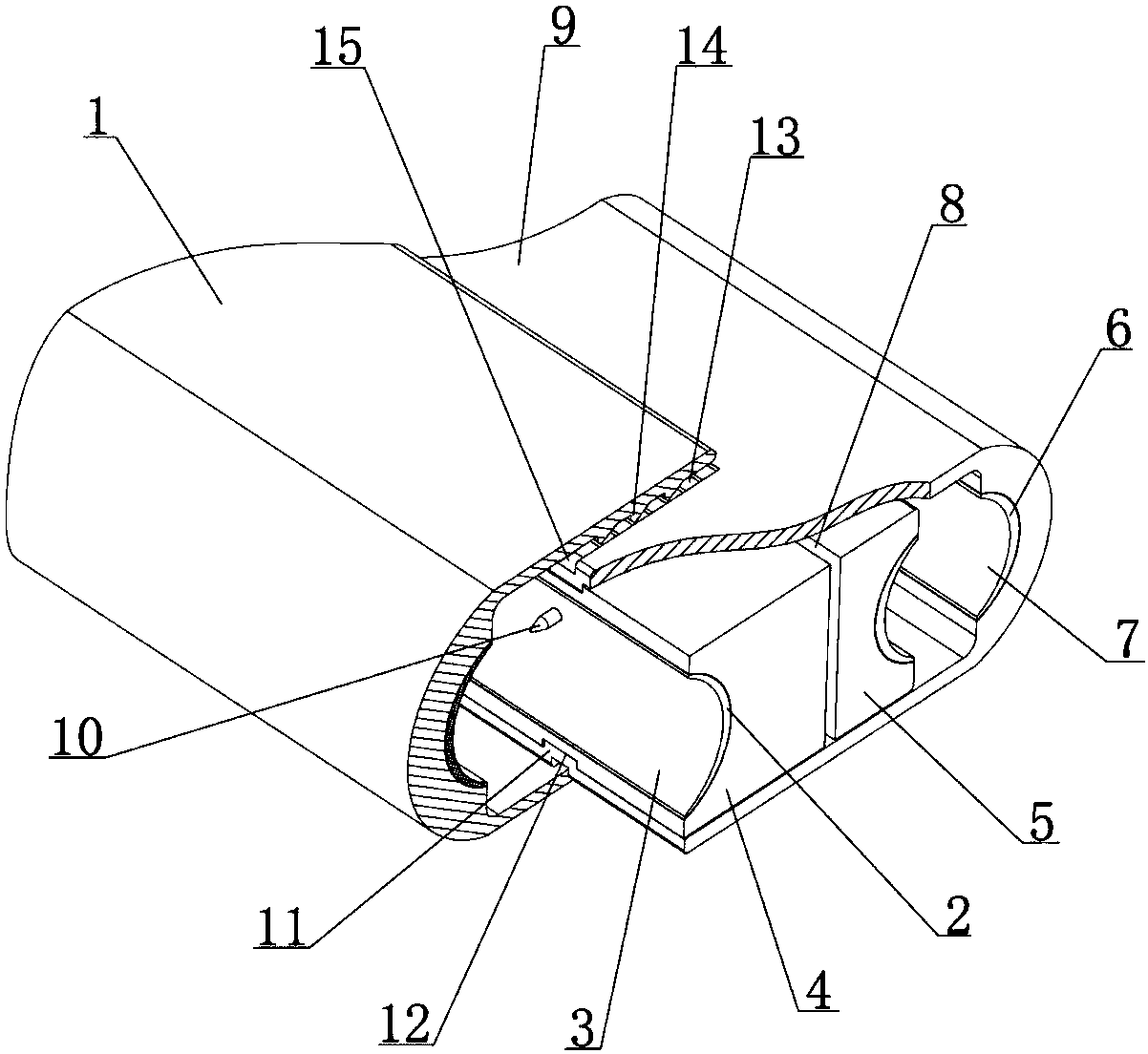

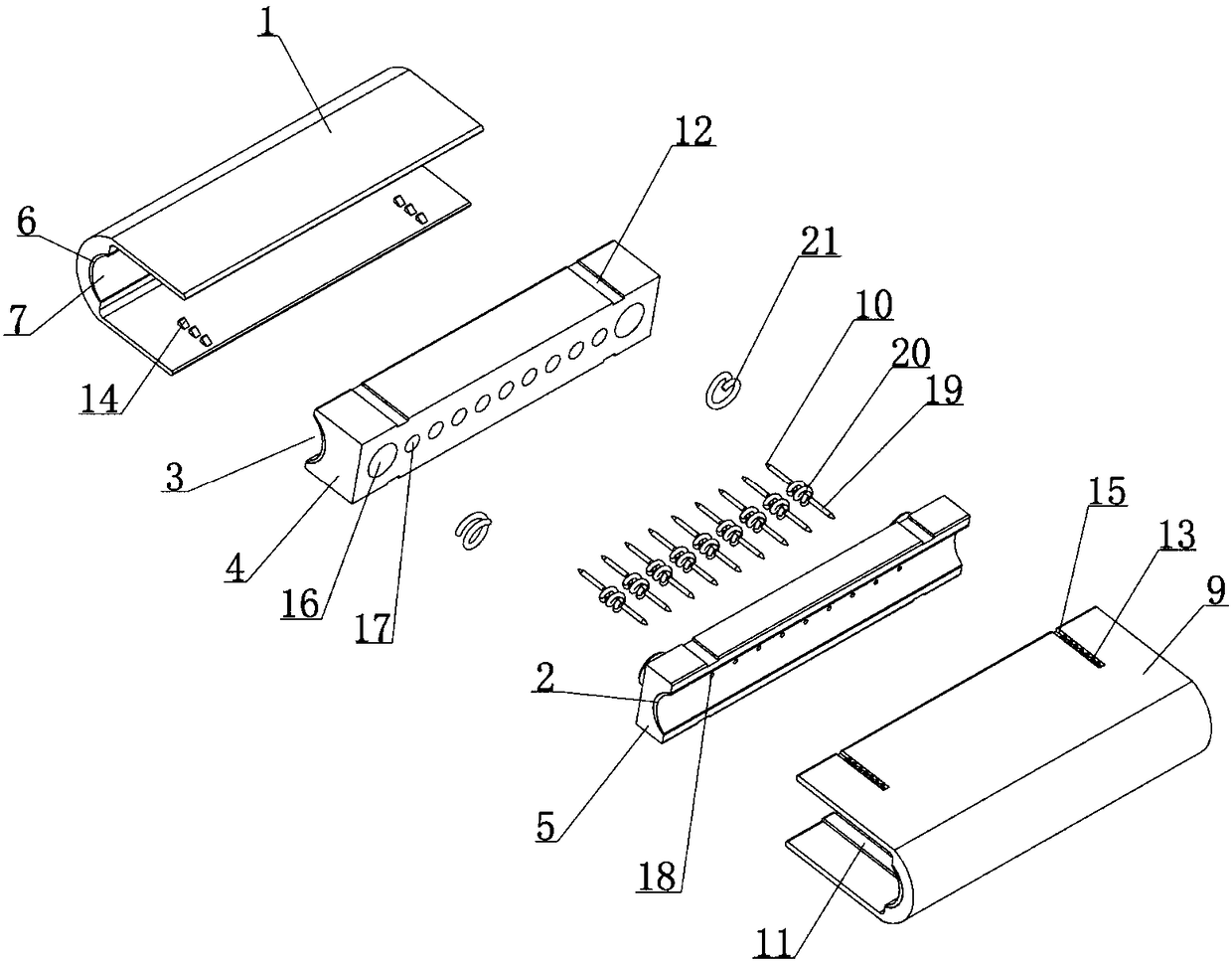

[0051] see figure 1 , 2 As shown, a cable insulation piercing clamp disclosed by the present invention is mainly composed of two parts: a wire clamp assembly and a wire clamp shell assembly;

[0052] Among them, see Figure 1-5 As shown, the wire sandwich assembly is in the shape of a cuboid as a whole, and its left and right side walls are respectively provided with a cable groove 3, and the two cable grooves 3 are parallel to each other, and the groove walls are respectively lined with sealing rubber pads 2; The sandwich assembly is composed of a left core block 4 and a right core block 5 with a buffer gap 8, and a transverse guide mechanism A and a thrust spring 21 are arranged between the left core block 4 and the right core block 5 to make the wire sandwich assembly in the width direction It can be elastically stretched, and the size of the buffer gap 8 changes accordingly when the wire sandwich assembly elastically expands; there are N parallel guide wire holes 18 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com