Motor and motor driving circuit

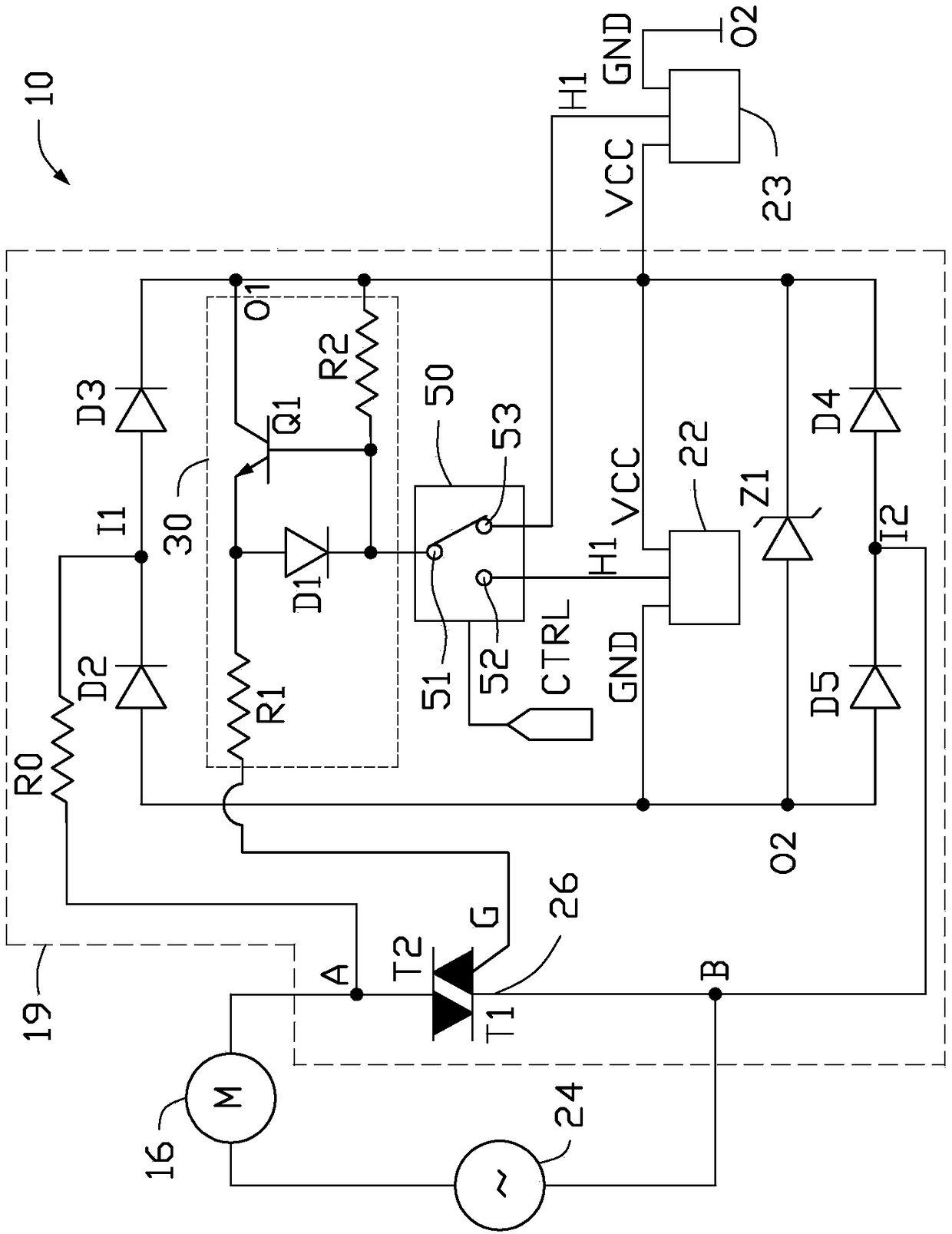

A motor drive circuit and motor drive technology, which is applied in the direction of electric components, single-phase motor control, electrical components, etc., can solve the problems of complex structure of forward and reverse control circuits, and achieve the effect of simple structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0048] In other implementation manners, the stator winding 16 and the controllable bidirectional AC switch 26 are connected in series between the first node A and the second node B, and the external AC power supply 24 is connected to the first node A and the second node B. between Node B.

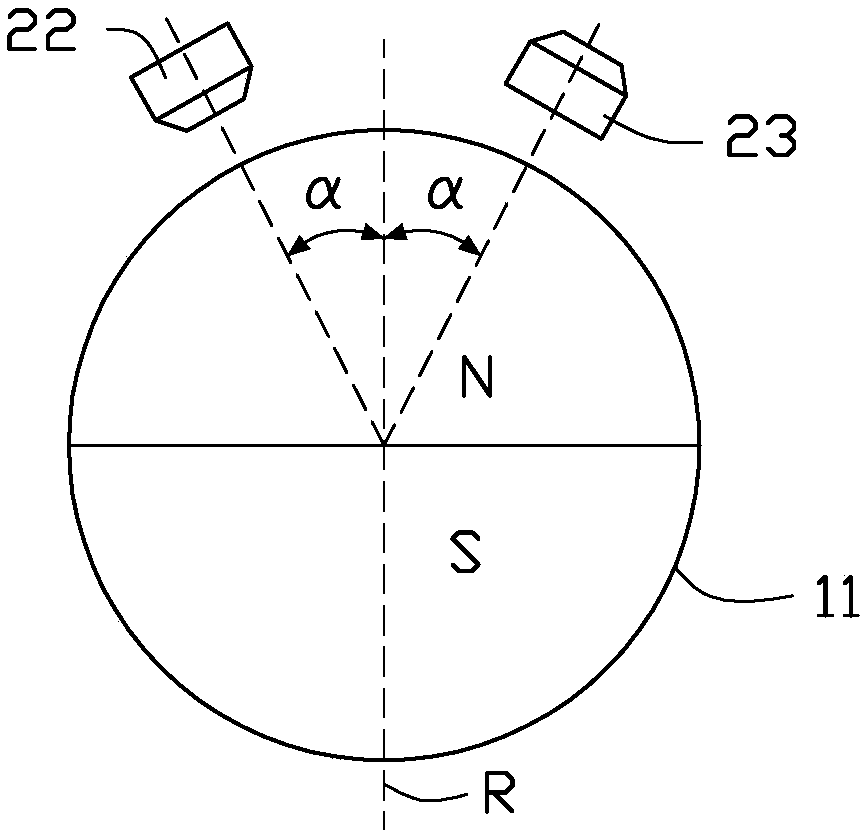

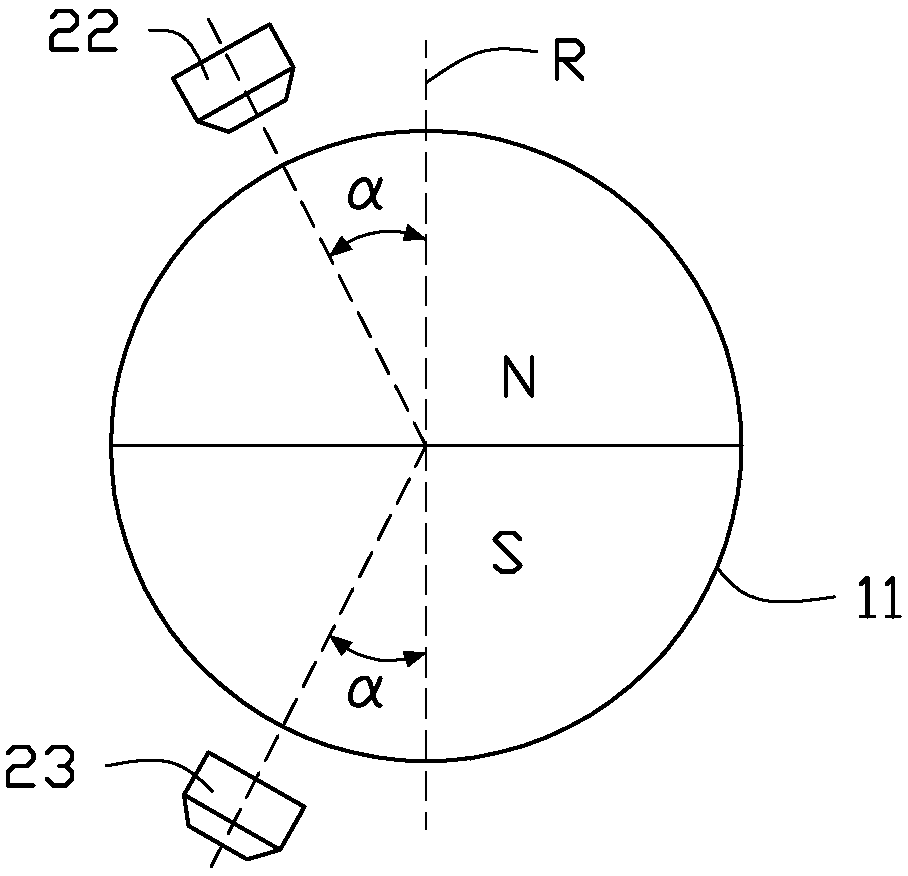

[0049] The first detection circuit and the second detection circuit detect the magnetic pole position of the motor rotor 11 respectively, and output a corresponding magnetic pole position signal, such as 5V or 0V, at their output terminals. The first detection circuit and the second detection circuit are preferably Hall sensors, such as linear Hall sensors or switch-type Hall sensors, which are respectively denoted as the first Hall sensor 22 and the second Hall sensor in this embodiment. twenty three. Of course, in other implementation manners, the first and second detection circuits may also be photoelectric encoders. Both the first Hall sensor 22 and the second Hall sensor 23 include a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com