Air purification and dust removal device

An air purification and dust collector technology, applied in the field of air purification treatment, can solve the problems of high cleaning frequency, high labor intensity, inconvenient use, etc., and achieve the effect of improving air quality, low replacement cost and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

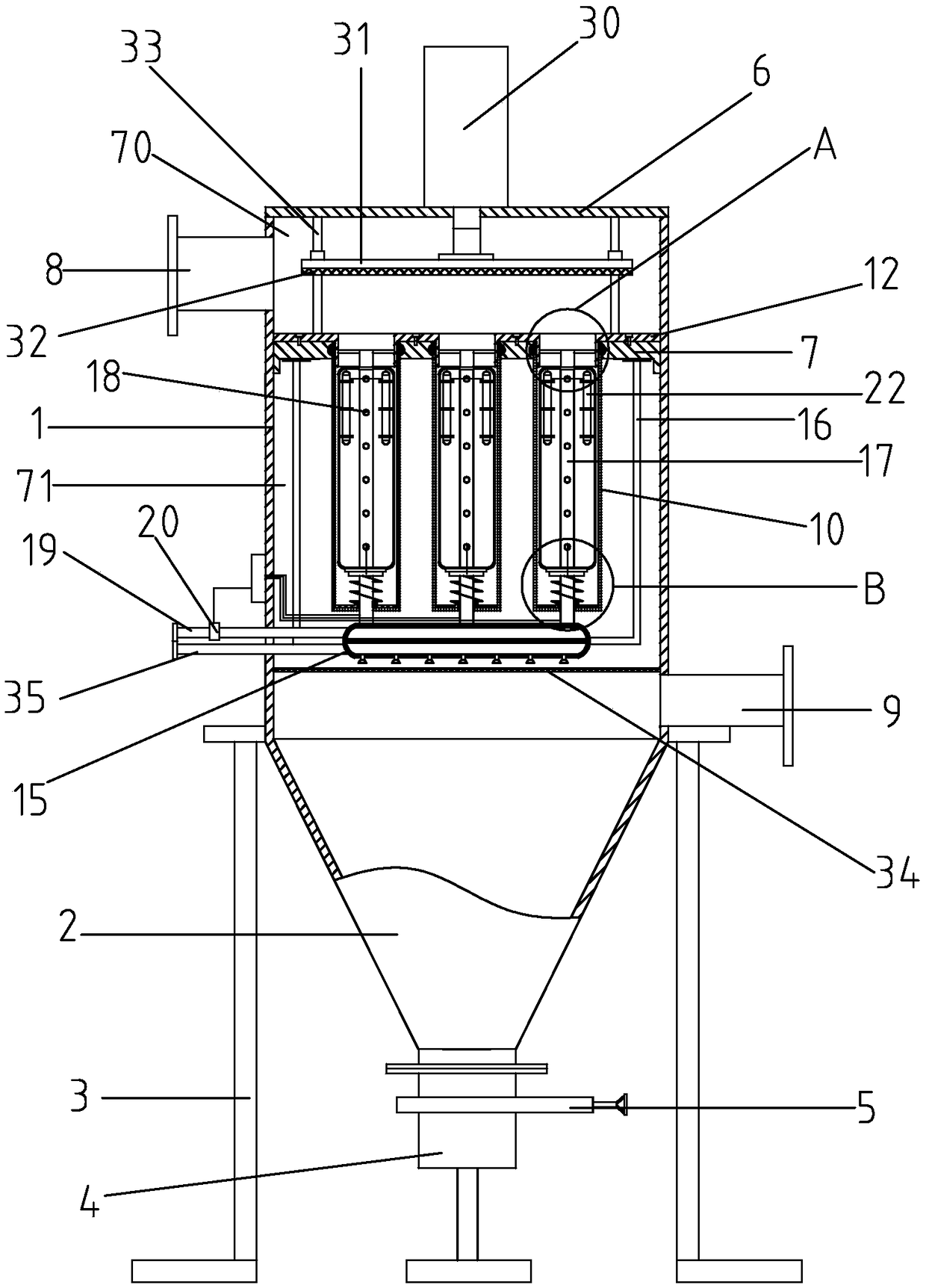

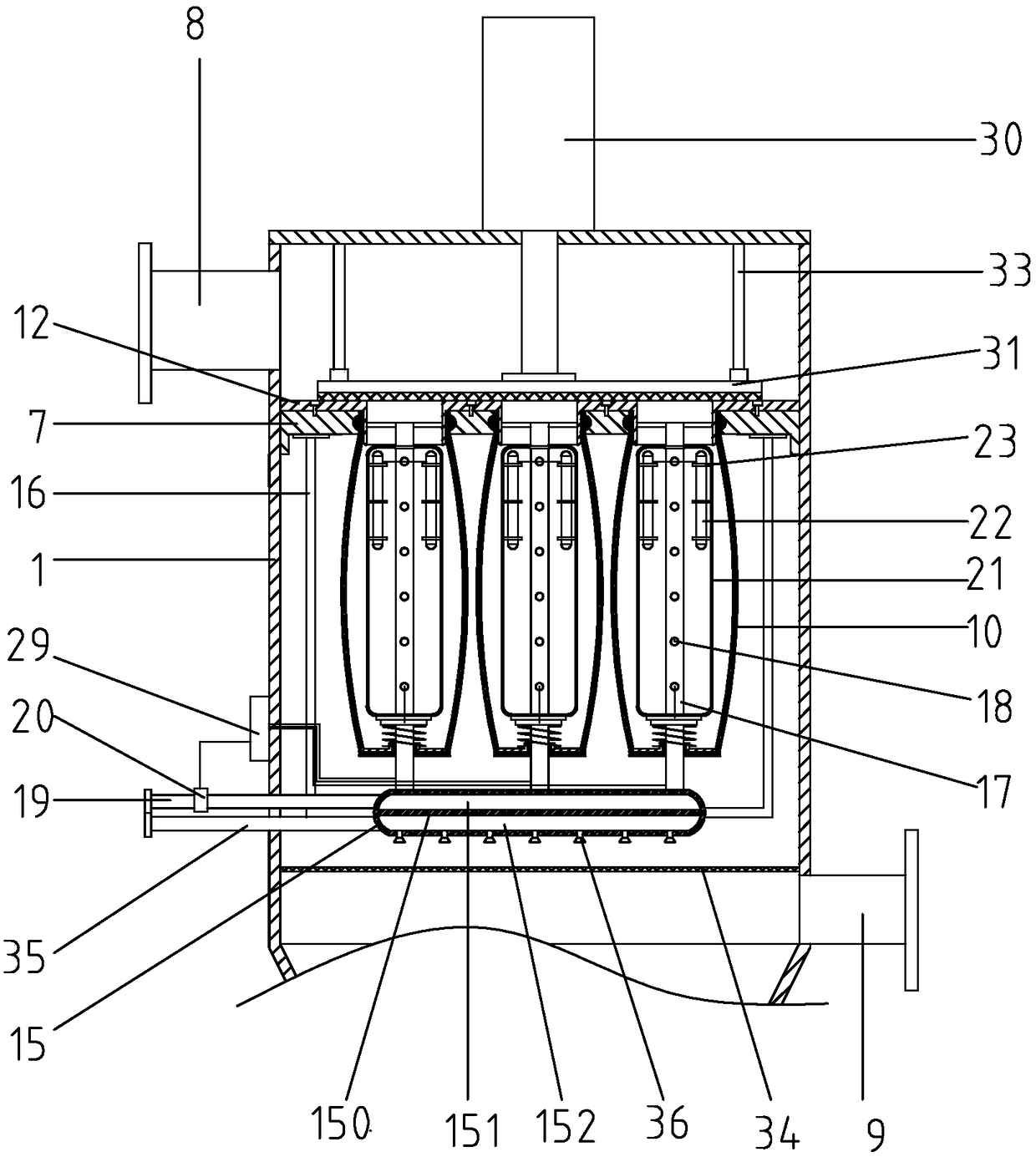

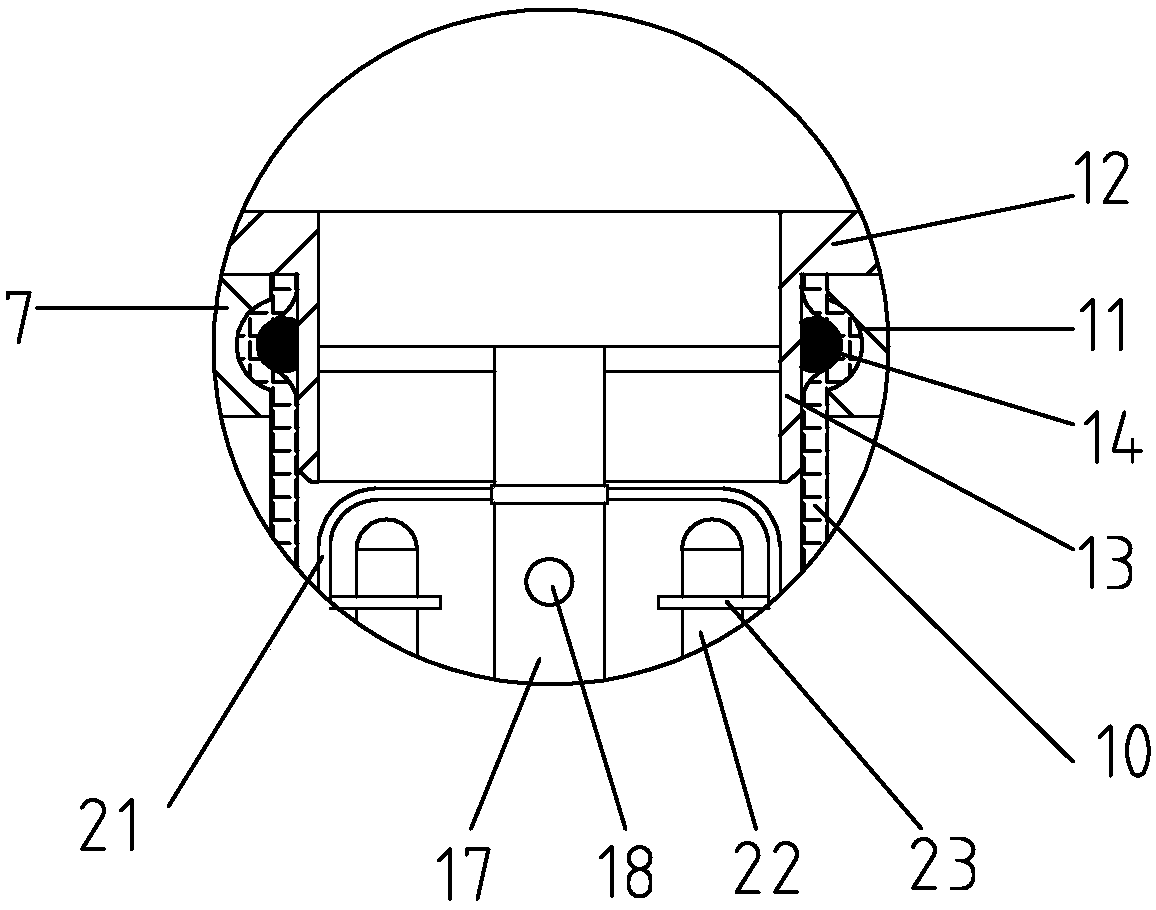

[0023] Such as figure 1 and figure 2 The shown air purifying dust collector comprises a housing 1, a dust collecting hopper 2 connected to the lower end of the housing, a support frame 3 is provided on the outside of the dust collecting hopper, and a slag discharge pipe 4 is provided at the lower end of the dust collecting hopper. A slag discharge valve 5 is provided on the slag pipe, a top cover 6 is provided on the top of the shell, and a base plate 7 is provided inside the shell. The base plate divides the space in the shell into an upper cavity 70 and a lower cavity 71. An exhaust pipe 8 communicating with the upper chamber is provided, and an air intake pipe 9 communicating with the lower chamber is provided on the side of the lower end of the housing; image 3 As shown, a number of positioning holes are provided on the base plate, and a filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com