Synchronous conveying, lifting and adjusting mechanism for automatic line

A technology of lifting adjustment and automatic line, which is applied in the direction of transportation packaging, transportation and packaging, external support, etc., can solve the problems of complex folding machine, difficult adjustment, increase the length of automatic line, etc., and achieve the effect of meeting the use requirements and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

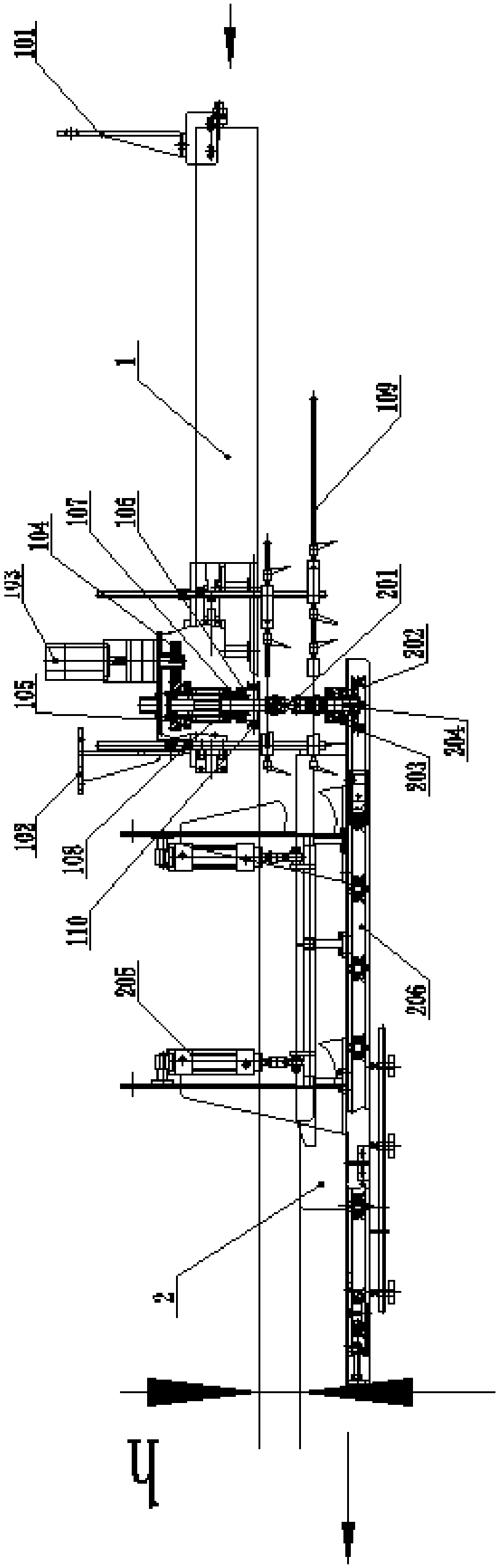

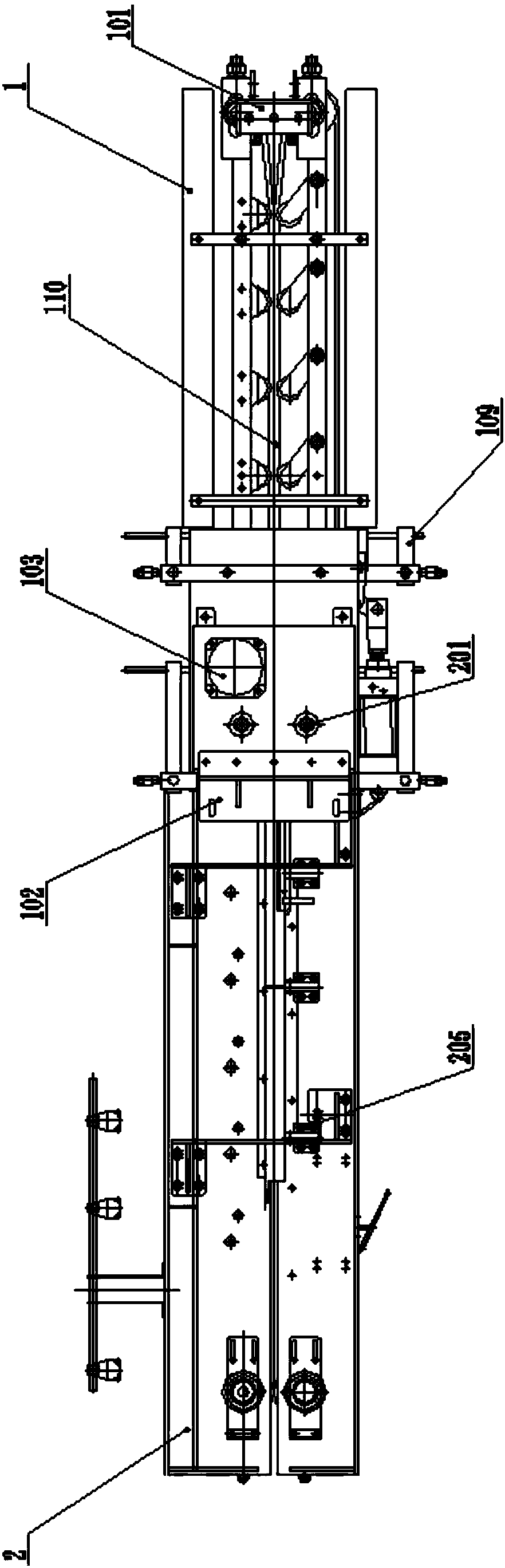

[0019] See attached picture.

[0020] A synchronous conveying lifting adjustment mechanism for an automatic line, including a jaw shaping machine 1 and an edge folding machine 2 that cooperate with each other. The two sets of pulleys 106 at the discharge end of the transmission belt of the jaw shaping machine 1 are respectively installed on the driving shaft 107. The two groups of driving wheels 202 at the feeding end of the transmission belt of the edge folding machine 2 are installed on the gear shaft 204 respectively, and the positions of the driving shaft 107 and the gear shaft 204 correspond up and down one by one, and they are respectively connected by a coupling 201. , the open end of the coupling 201 is respectively connected with two groups of driving shafts 107 on the jaw shaping machine 1, and the other end of the coupling 201 is connected with the gear shaft 204 respectively, and the cross section of the coupling 201 is uniform It is a splined structure with radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com