Transportation device

A transport device and container technology, which is applied in the field of non-standard container stacking transport devices, can solve the problems that the upper and lower container corners cannot be accurately aligned, cannot be arranged tightly, and reduce transportation safety, so as to reduce processing costs. Cost and transportation costs, material saving, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

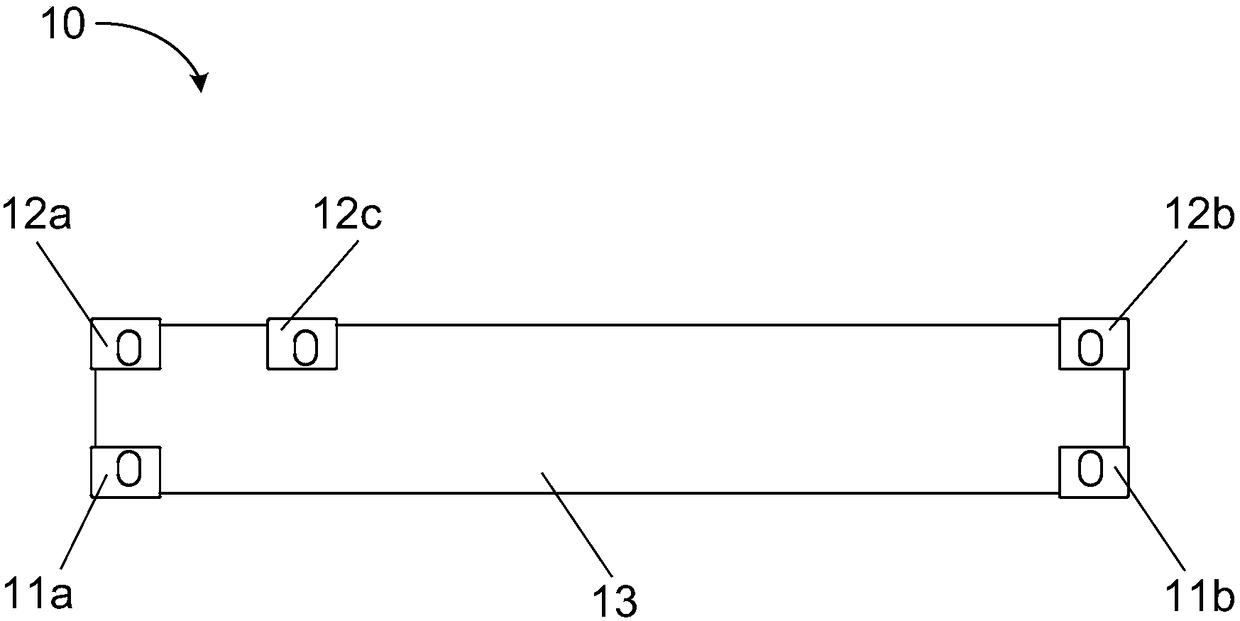

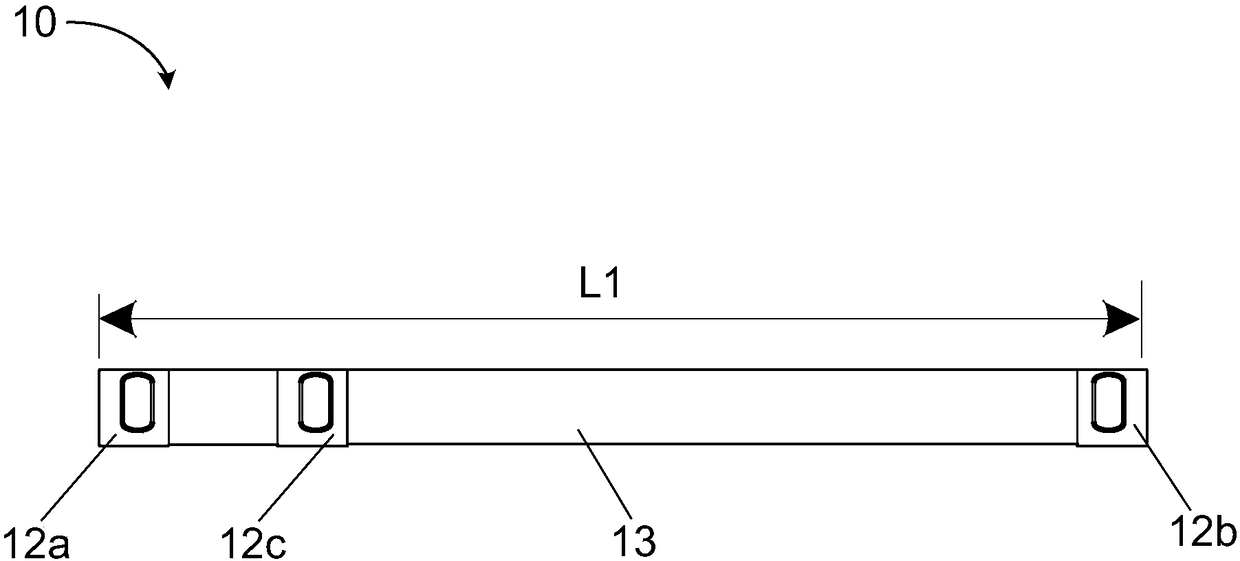

[0030] Such as Figure 1A and Figure 1B As shown, the transport unit 10 includes a support beam 13 . Support beam 13 is a steel beam. Preferably, the length L1 of the support beam 13 is adapted to the width of the standard container, so that the transport unit 10 can be aligned with the standard container in the width direction, thereby realizing a close arrangement in the width direction.

[0031] A first bottom corner piece 11a and a second bottom corner piece 11b are respectively arranged on the lower part of the support beam 13, and the center distance between the first bottom corner piece 11a and the second bottom corner piece 11b is the same as two The centers of the corner fittings are adapted so that the transport unit 10 can cooperate with the corner fittings of standard containers or the corner fittings of standard container spaces of container transport equipment through the first bottom corner fittings 11a and the second bottom corner fittings 11b.

[0032] Two ...

no. 2 approach

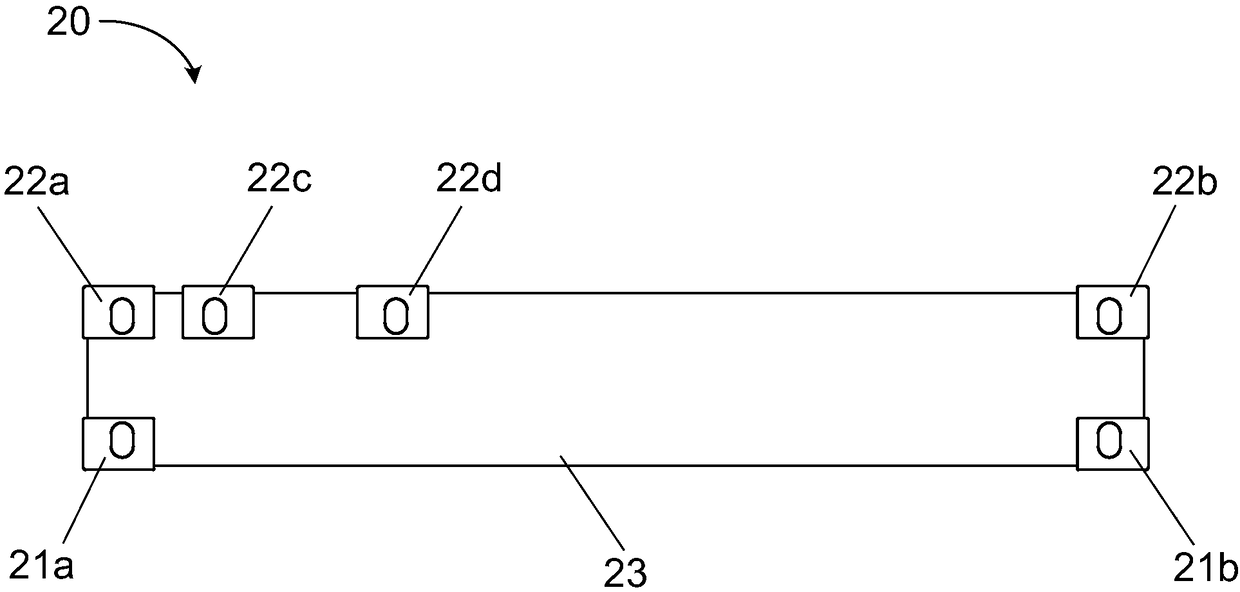

[0037] Such as Figure 2A and Figure 2B As shown, the transport unit 20 includes a support beam 23 . The support beam 23 is a steel beam. Preferably, the length L2 of the supporting beam 23 is adapted to the width of the standard container, so that the transport unit 20 can be aligned with the standard container in the width direction, thereby realizing a close arrangement in the width direction.

[0038] A first bottom corner piece 21a and a second bottom corner piece 21b are respectively arranged on the lower part of the support beam 23, and the center distance between the first bottom corner piece 21a and the second bottom corner piece 21b is the same as the width direction of the standard container. The centers of the corner fittings are adapted so that the transport unit 20 can cooperate with the corner fittings of standard containers or standard container positions of container transport equipment through the first bottom corner fittings 21a and the second bottom corn...

no. 3 approach

[0045] Such as Figure 3A and Figure 3B As shown, the transport unit 30 includes a composite beam 33 . The composite beam 33 is a rectangular frame structure composed of a first long beam 33 a , a second long beam 33 b and two short beams 34 . Preferably, the length L3 of the first long beam 33a and the second long beam 33b is adapted to the width of a standard container, so that the transport unit 30 can be aligned with the standard container in the width direction, thereby realizing a close arrangement in the width direction. In this embodiment, the bottom corner fittings and top corner fittings provided on the first long beam 33a are similar to the setting positions and functions of the bottom corner fittings and top corner fittings in the second embodiment shown in the present invention. For the sake of brevity, here will not be described in detail. It can be understood that the arrangement of the bottom corner fittings and top corner fittings on the first long beam 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com