Coal mine belt machine automatic inspection robot

An automatic inspection and robot technology, applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of poor working environment of coal mine belt conveyors, unsatisfactory driving methods, and inability to realize all-day monitoring, etc. Achieve the effects of avoiding uneven force, large bearing capacity, and reduced motion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

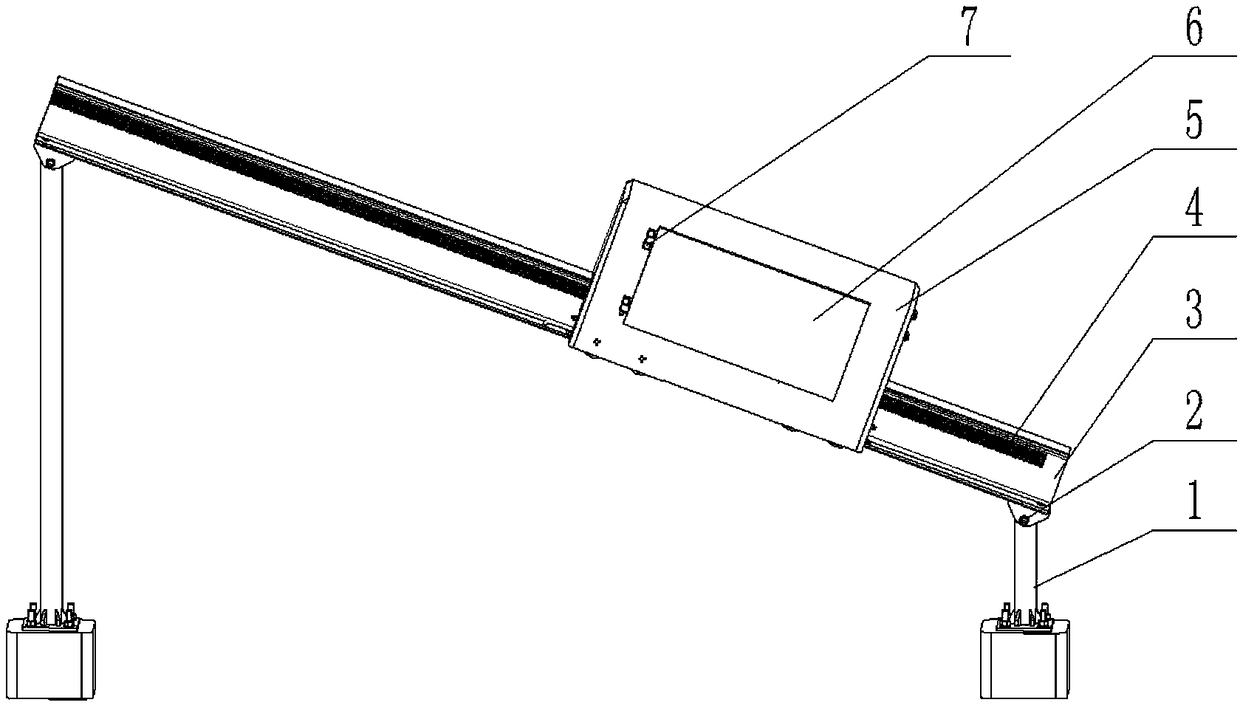

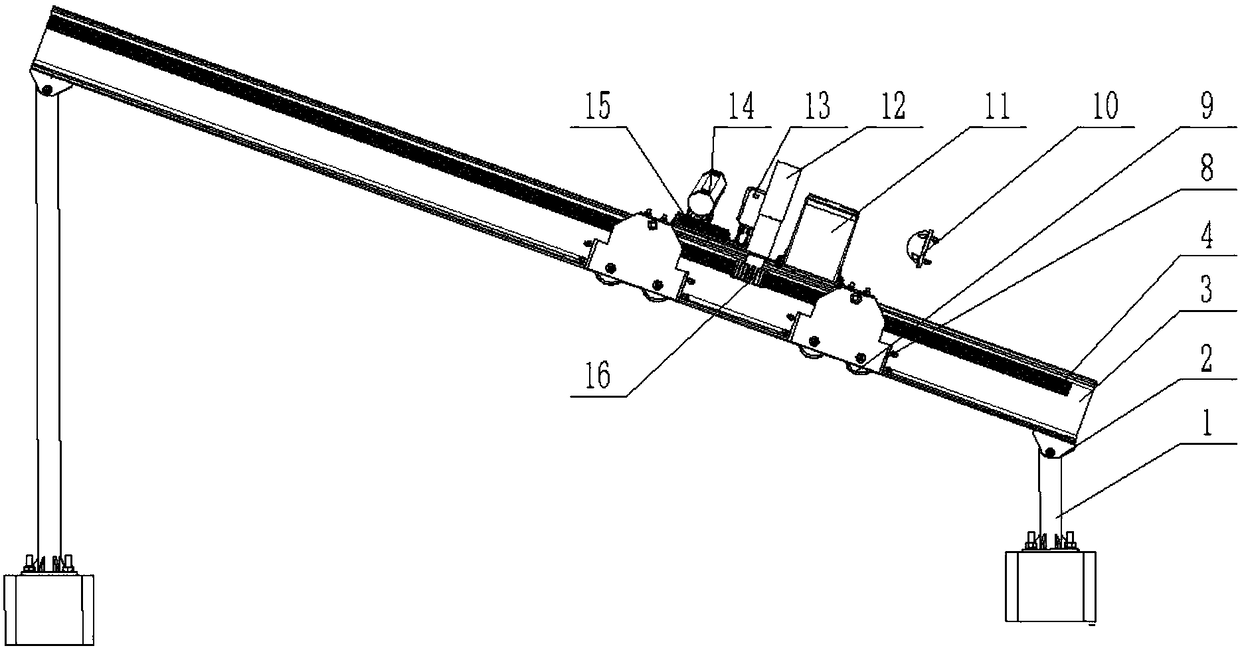

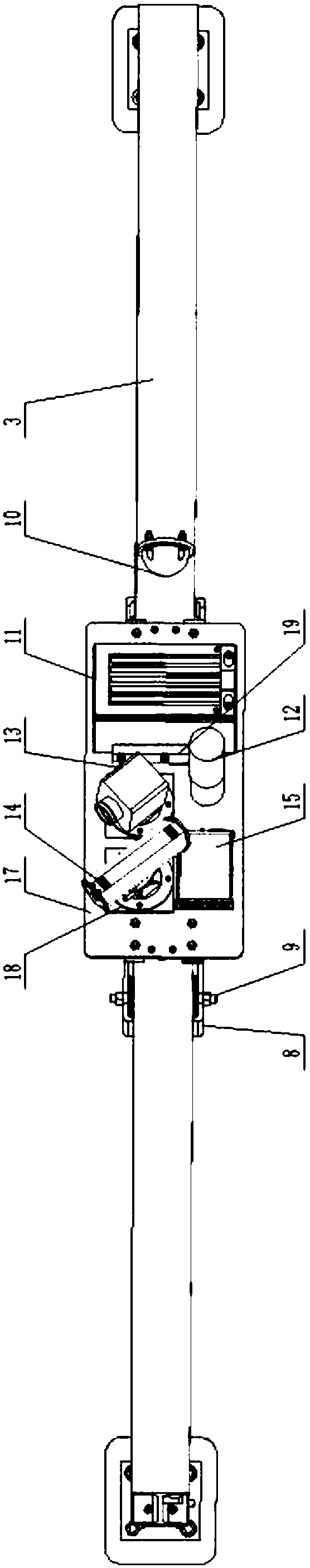

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1-Figure 4 As shown, a coal mine belt conveyor automatic inspection robot includes a track-type walking unit and a robot control system, a chassis shell 5, an I-steel track 3, an inclined base 2 and a column 1, and the track-type walking unit and robot control The system is installed in the chassis shell 5 and erected on the I-shaped steel track 3, the two ends of the lower surface of the bottom surface of the I-shaped steel track 3 are respectively provided with inclined bases 2, and the one inclined base 2 is connected to the column one and the other The inclined base is connected to the second column, and the lengths of the first column and the second column are not equal, and the columns are connected by anchor bolts embedded in the cement pile;

[0029] The track-type walking unit includes a driving part and a guiding part,

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com