Capping machine with homo-directional cap stabilizing mechanism

A technology of capping machine and fuselage, which is applied in the direction of capping containers tightly with caps, threaded caps, bottle/container caps, etc. It can solve problems such as easy crooked locking of caps, large wear of caps, and loose locks. Achieve simple and fast operation, improve work efficiency, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

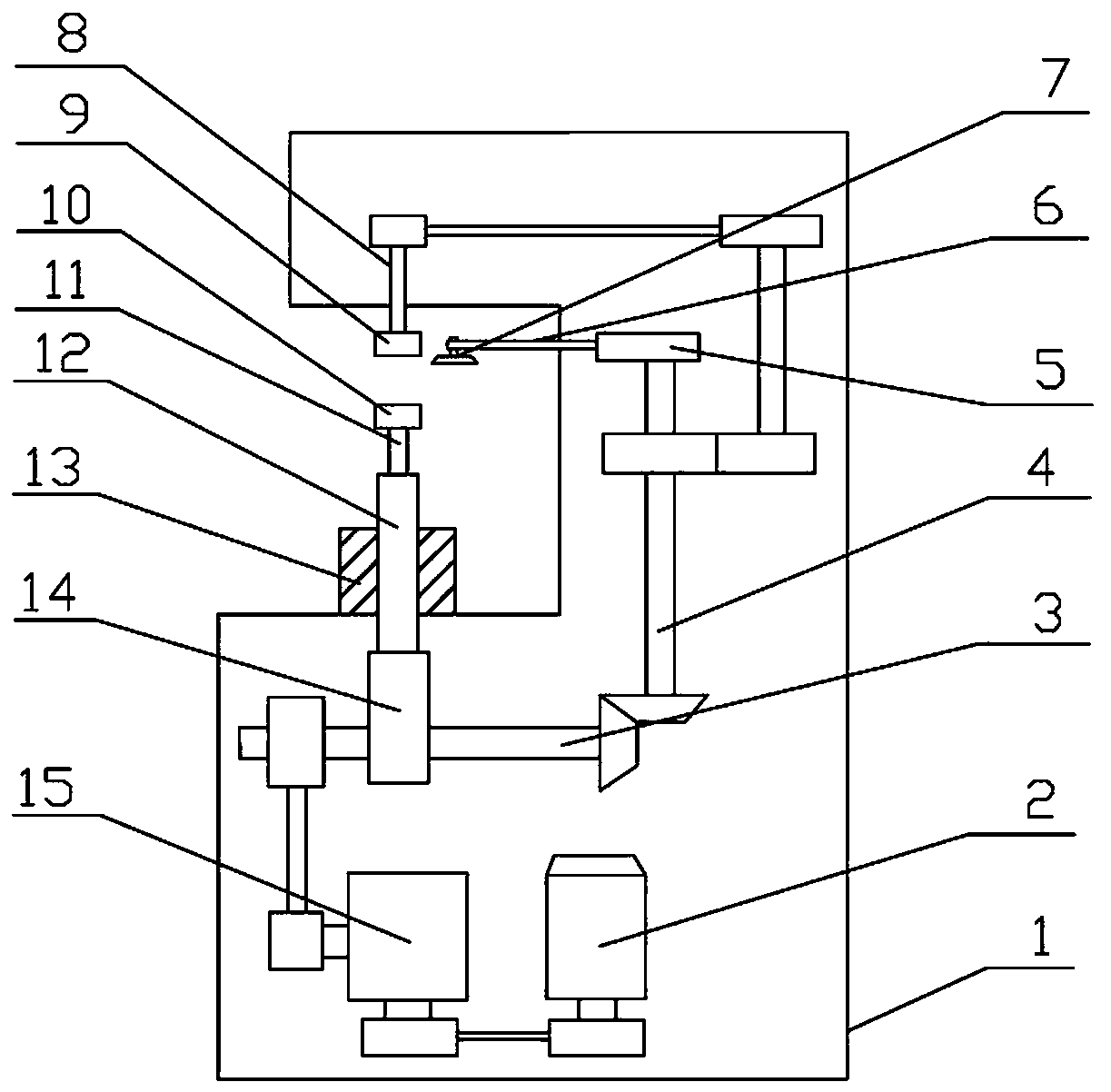

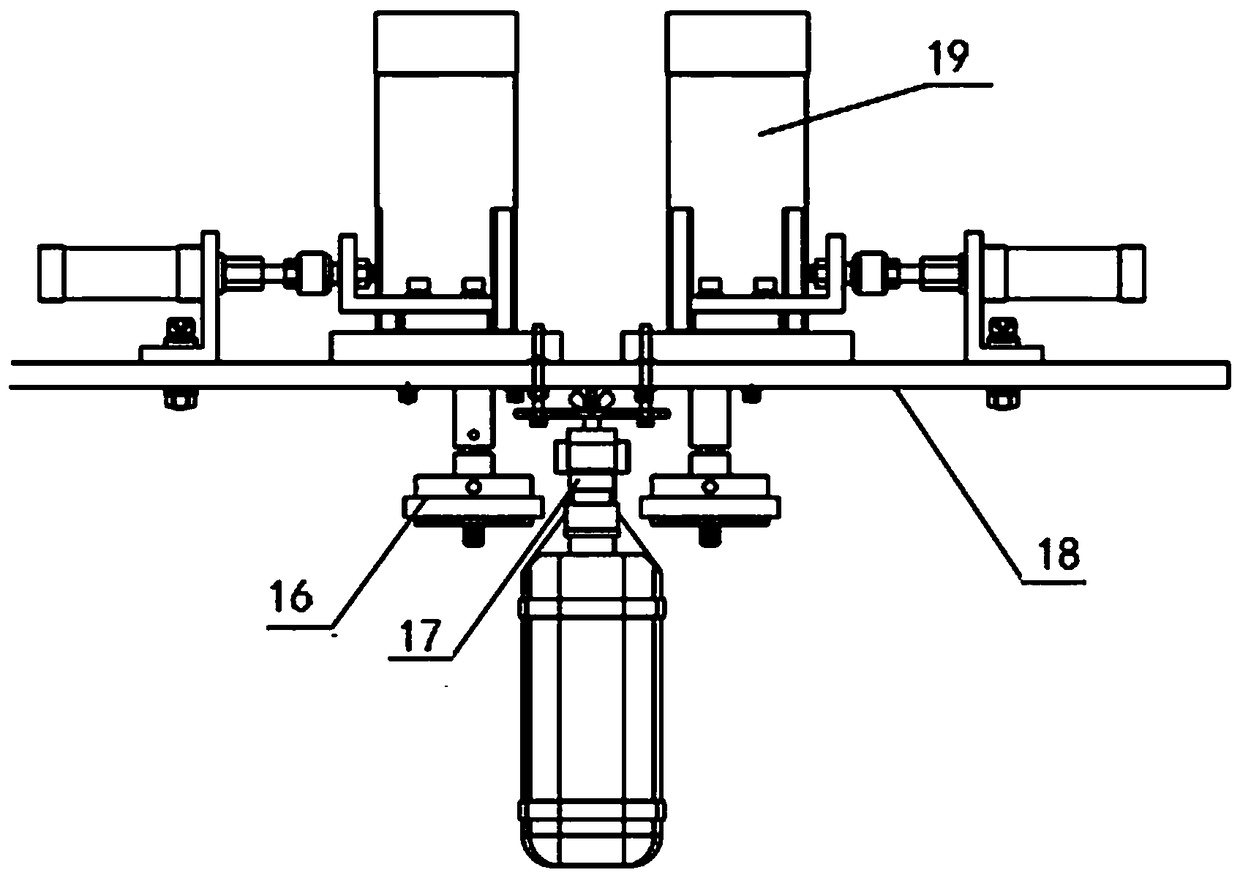

[0014] according to Figure 1~2 The specific structure of the present invention will be described in detail. The cap locking machine with the same direction stabilizing mechanism includes a body 1, a motor 2, the motor 2 is connected to the horizontal transmission shaft 3 through the reducer 15, the horizontal transmission shaft 3 is connected to the vertical transmission shaft 4 through the bevel gear, and the horizontal transmission shaft 3 is A vertical cam 14 is installed, and a horizontal cam 5 is installed on the vertical transmission shaft 4; the shaft sleeve 13 is installed on the working surface of the fuselage 1, the vertical shaft 12 is movably installed in the shaft sleeve 13, and the lower end of the vertical shaft 12 is connected with the cam , the lower mold 10 is connected to the vertical shaft 12 through the adjusting screw 11; the upper mold 9 is installed on the rotating shaft 8 at the upper end of the fuselage 1, and the rotating shaft 8 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com