High-strength and anti-corrosion composite pattern steel and manufacturing method thereof

A manufacturing method, patterned steel technology, applied in the direction of manufacturing tools, chemical instruments and methods, metal rolling, etc., can solve the problem of increased load distribution, unstable production, large differences in physical parameters of composite patterned plates, high temperature deformation characteristics, etc. problems, to achieve the effect of high surface quality, no cracking and delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

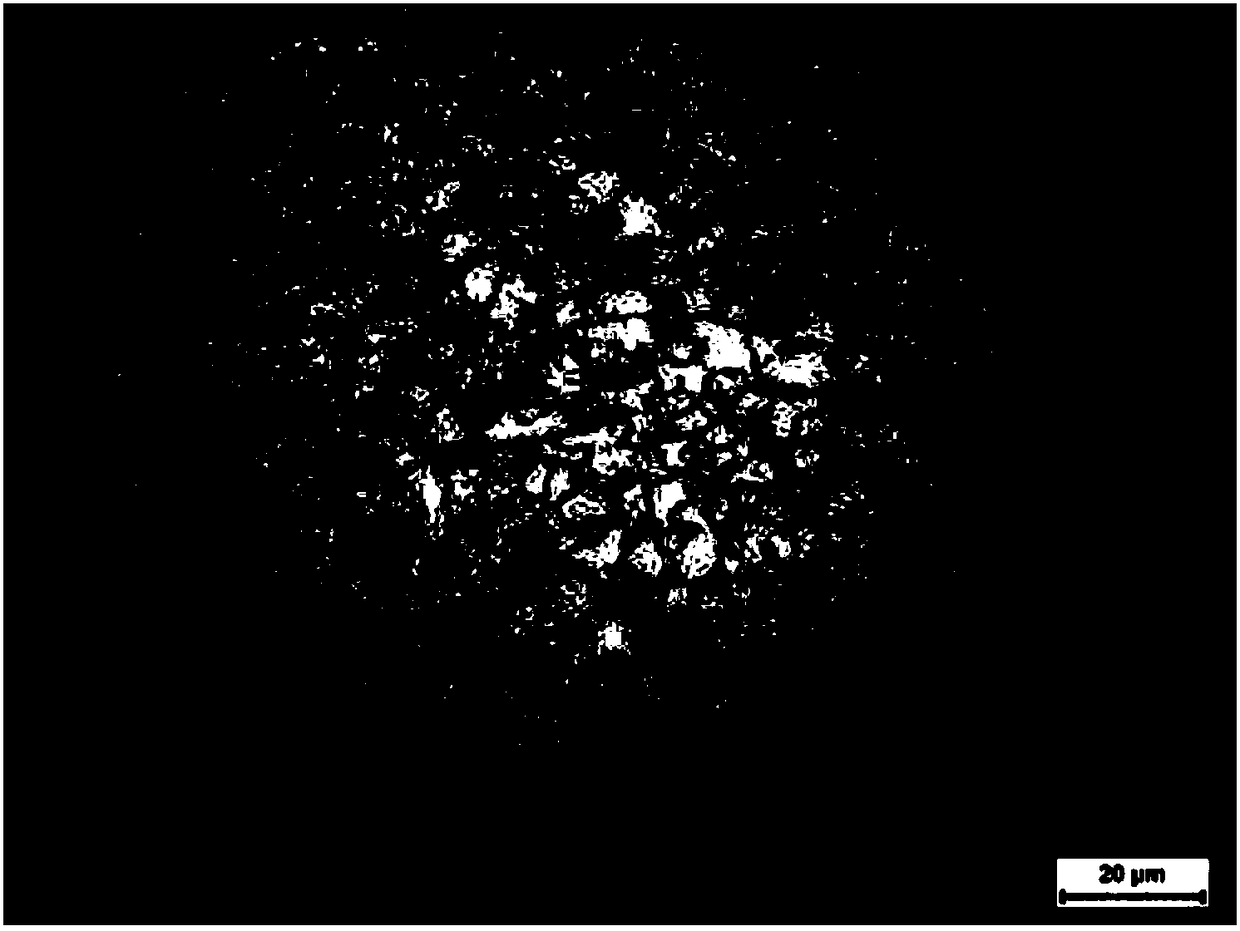

Image

Examples

Embodiment 1-4

[0057] Table 1 lists the mass percentages of chemical elements in each blank layer in the high-strength corrosion-resistant composite patterned steel of Examples 1-4.

[0058] Table 1. (wt%, the balance is Fe and other unavoidable impurities except P and S)

[0059]

[0060] The manufacturing method of the high-strength corrosion-resistant composite patterned steel of embodiment 1-4 adopts following steps to make (concrete process parameter in each embodiment is referring to Table 2):

[0061] (1) make substrate slab and cladding slab according to each chemical composition listed in Table 1;

[0062] (2) Assembling the substrate slab and the multi-layer slab, welding and sealing around the bonding surfaces of each layer, and then vacuuming;

[0063] (3) Composite rolling: first heat the billets at a temperature of 1100-1180°C, and then perform multi-pass rolling to obtain a composite steel plate. The total reduction rate is controlled to be not less than 70%, and the final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com