Freely-adjusted concrete polishing machine for building

A concrete grinder and construction technology, applied in construction, roads, road repairs, etc., can solve the problems that aggregates cannot be polished quickly, reduce construction efficiency, and high labor intensity, so as to reduce the difficulty of polishing and reduce construction costs. Difficulty, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

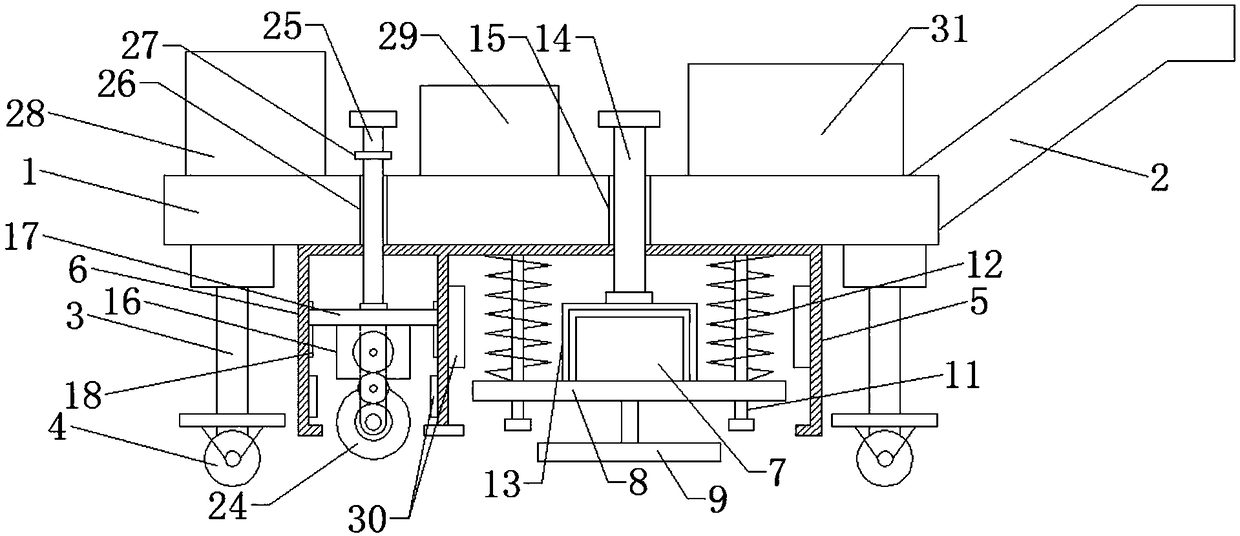

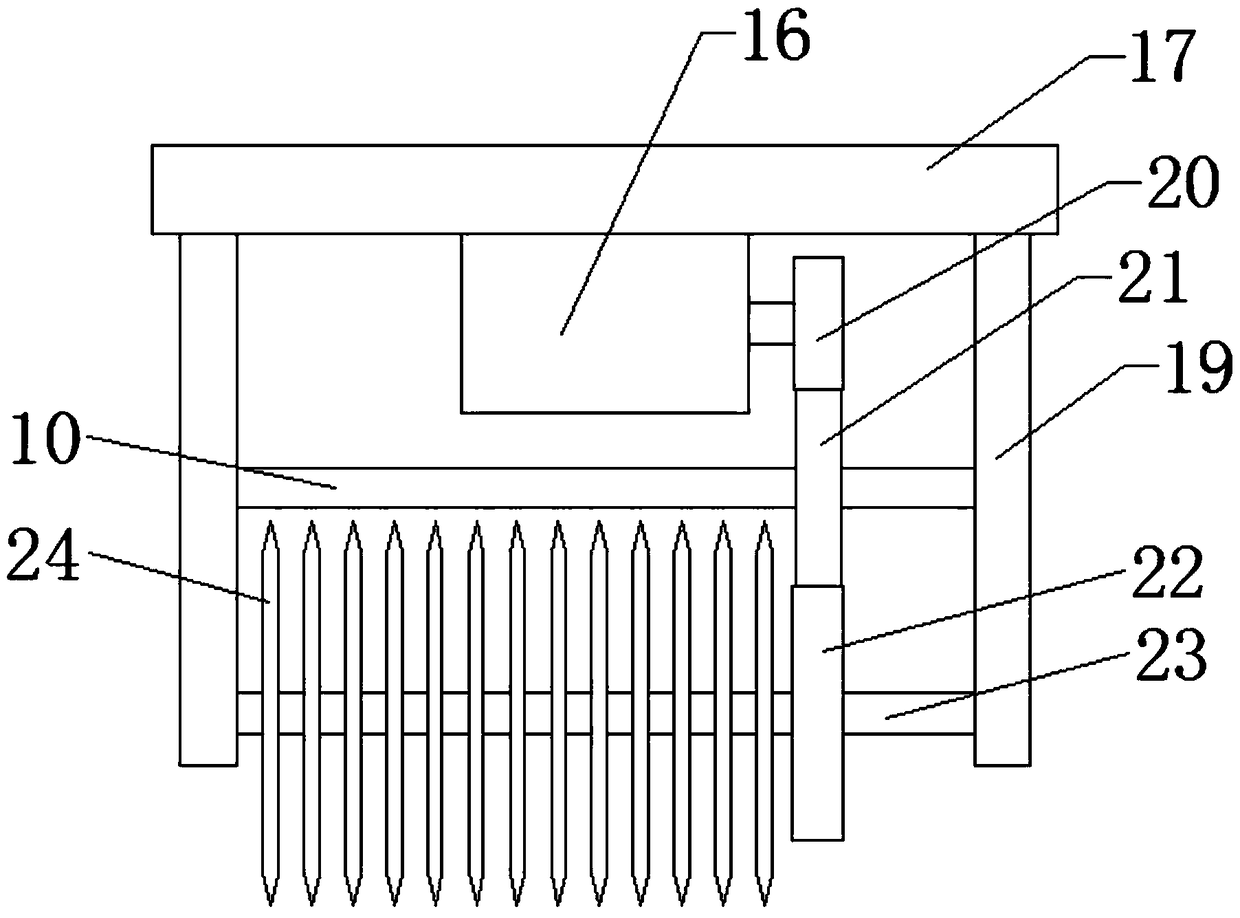

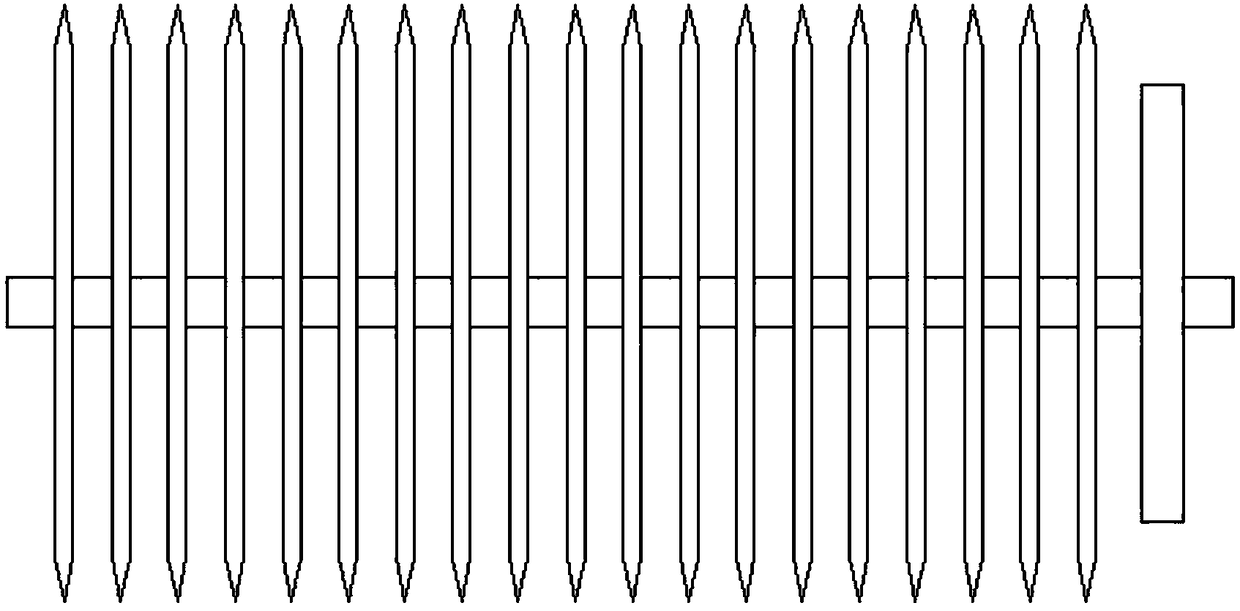

[0021] Please refer to the figure, in an embodiment of the present invention, a free-adjustable construction concrete grinder includes a vehicle frame 1, an armrest 2, legs 3, rollers 4, a polishing motor 7 and a grinding disc 9; the armrest 2 It is fixedly welded on the vehicle frame 1, and the vertical legs 3 are fixed on the four corners of the lower side of the vehicle frame 1. The roller 4 is installed at the lower end of the leg 3, and the equipment is moved conveniently through the roller 4, which is convenient for the equipment to be pushed; on the vehicle frame 1 is fixed with an electric box 31, and the inside is provided with electrical components, which are driven by electric energy for the equipment.

[0022] The lower side of the vehicle frame 1 is fixed with a polishing chamber 5 and a cutting chamber 6 with the opening facing downwards, and the polishing chamber 5 is located at the cutting chamber 6 rear end (in the figure 1 Middle right is the rear end).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com