Method for calculating power consumption of frequency-conversion circulating water pump

A technology of circulating water pump and calculation method, applied in pump testing, liquid variable capacity machinery, machine/engine, etc., can solve the problem of inability to accurately calculate the power consumption of variable frequency circulating water pump, and achieve error resolution, accurate data support, power consumption accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

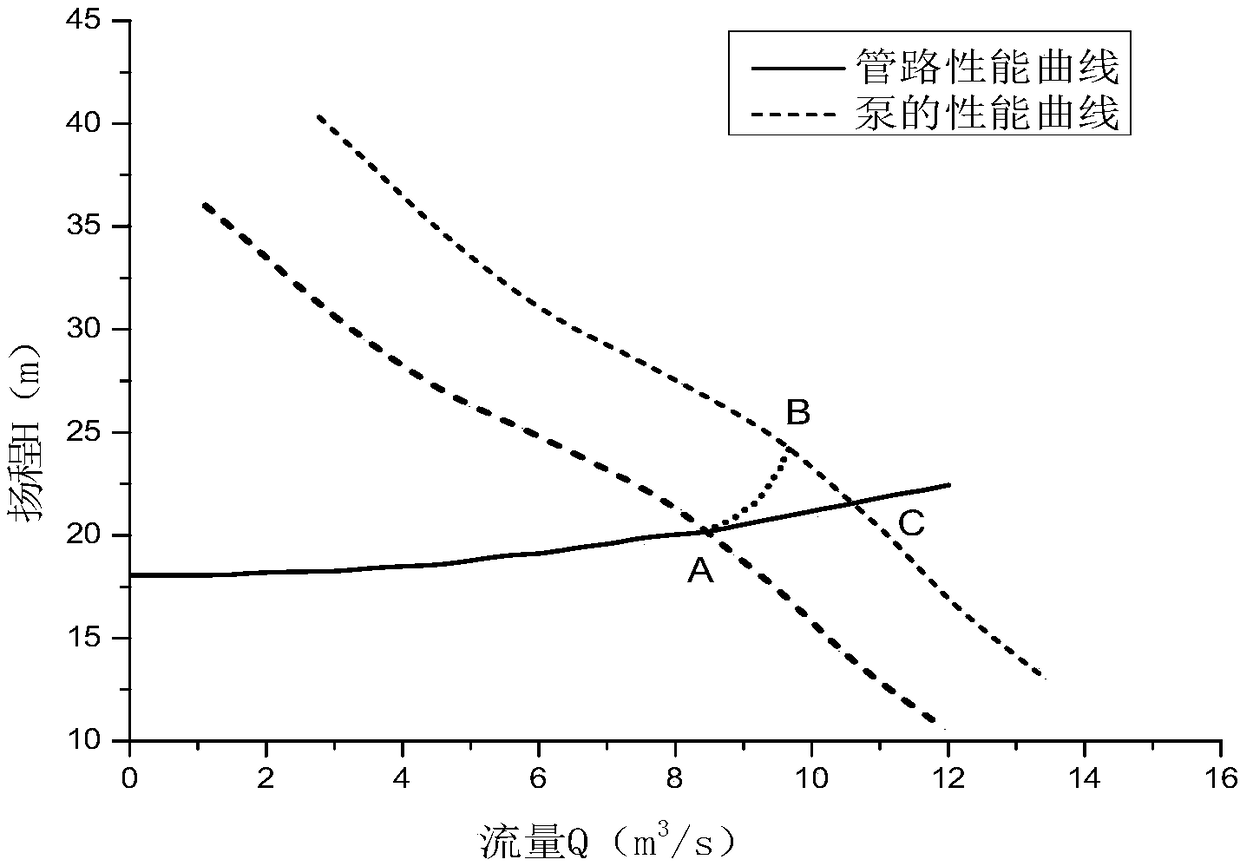

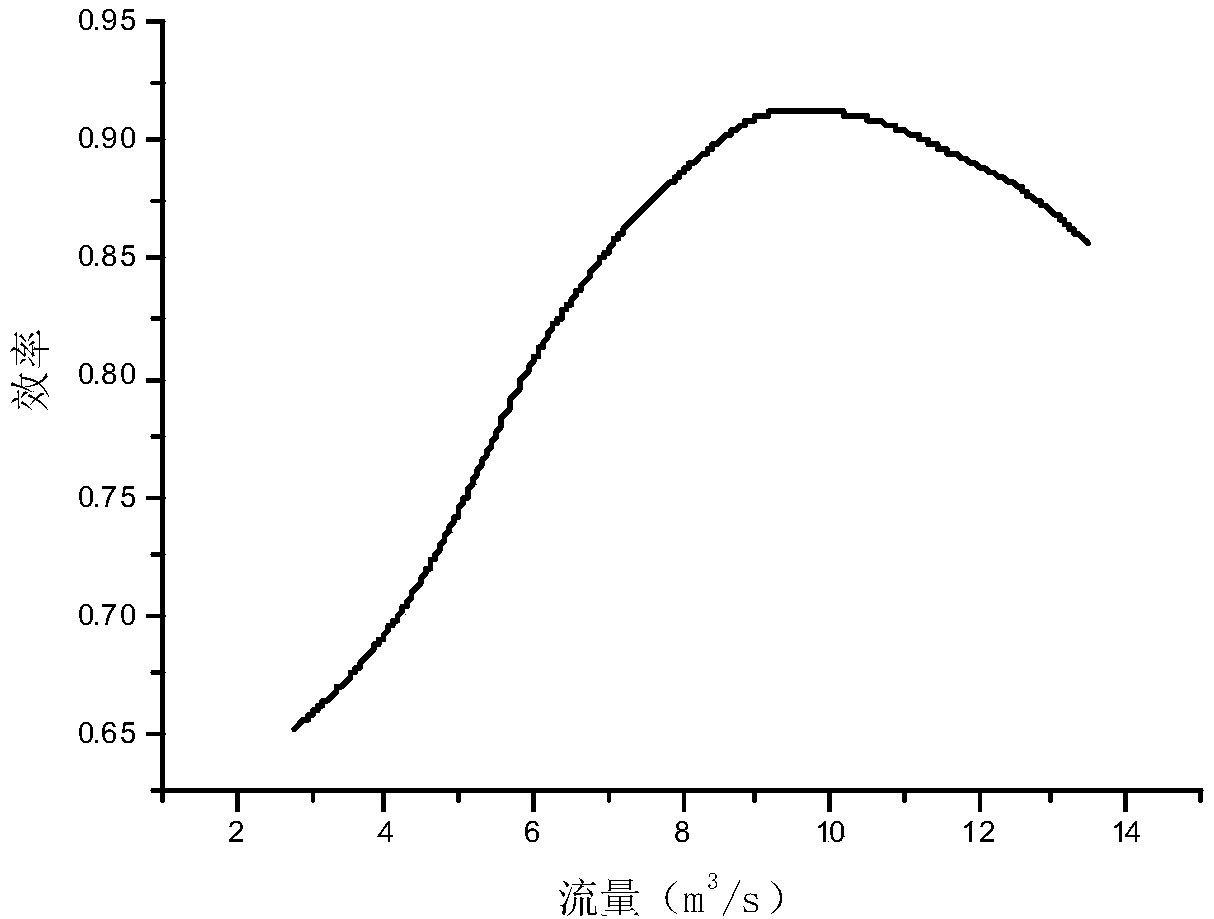

[0033] figure 1 The pump performance curve and pipeline performance curve of the circulating water pump shown, figure 2 Shown is the efficiency-flow curve of the pump at rated speed. Among them, the basic performance parameters of the circulating water pump mainly include flow Q, head H, power P, speed n, speed ratio α, and efficiency η.

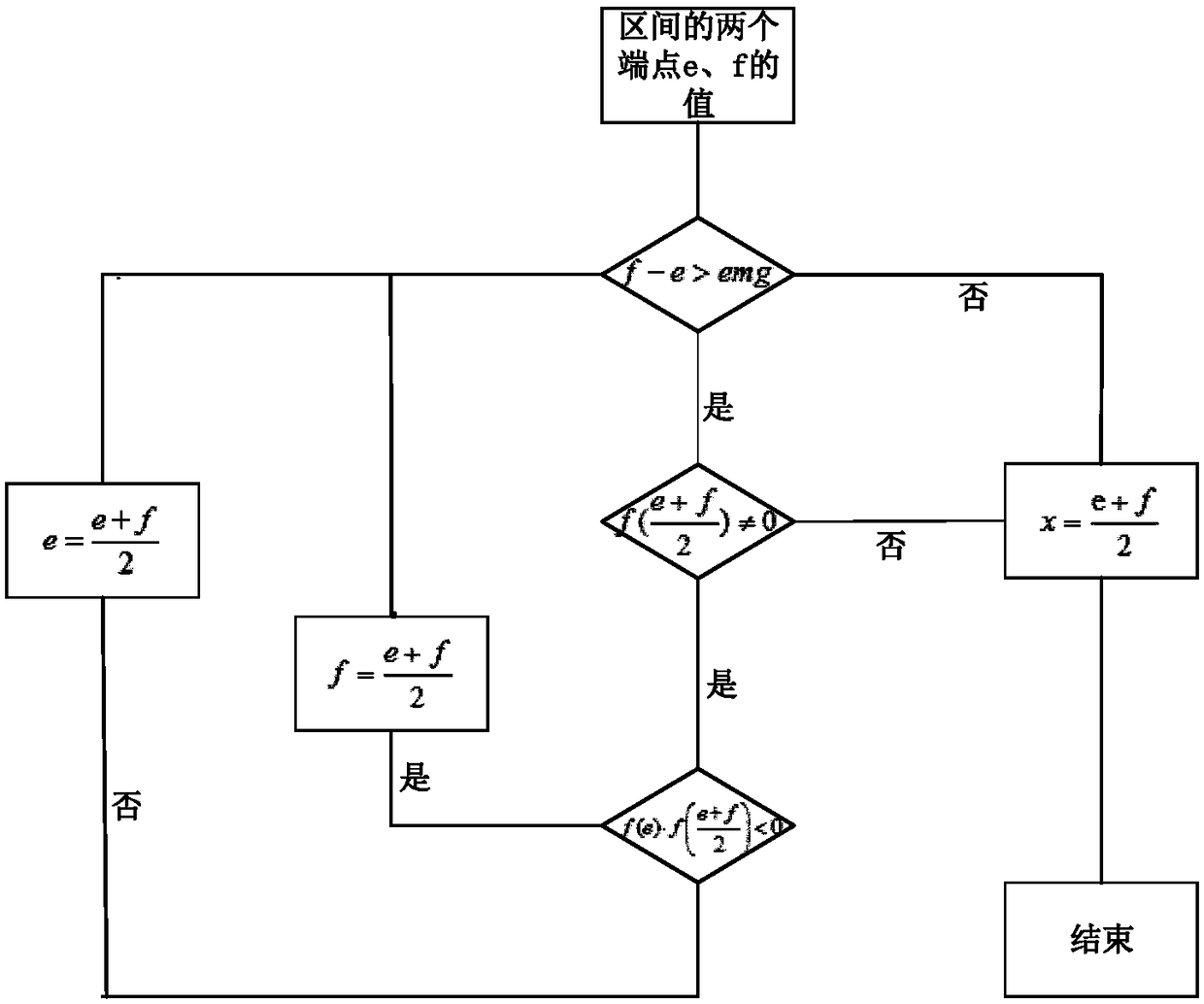

[0034] The power consumption calculation method of a single variable frequency circulating water pump, the specific steps are as follows:

[0035] (1) Use origin software to fit the performance curve expression, pipeline performance curve expression and η-Q expression of the pump at the rated speed according to the curve diagram of the circulating water pump, as follows:

[0036] Pump performance curve expression: H=aQ 2 +bQ+c (1)

[0037] Pipeline performance curve expression: H=kQ 2 +H 0 (2)

[0038] η-Q expression: η=f(Q) (3)

[0039] Among them, H is the actual head at any speed of the variable frequency circulating water pump,...

Embodiment 2

[0062] Two identical circulating water pumps run in parallel after frequency conversion, and the speed ratios after frequency conversion are α 1 、α 2 , according to the analysis of the performance curve of a single variable frequency pump in Embodiment 1, the expression of the performance curve of the pump of two parallel variable frequency pumps can be drawn as:

[0063]

[0064] According to the parallel connection characteristics of the water pump, it can be known that: H=H 1 =H 2 , Q=Q 1 +Q 2 , the operating condition point formula of the frequency conversion after the circulating water pump is connected in parallel is as follows:

[0065]

[0066] Transform the above formula to get:

[0067]

[0068] In order to ensure that the above equations have solutions, the constraints are as follows:

[0069]

[0070] Among them, H is the actual head at any speed of the variable frequency circulating water pump, Q is the actual flow rate at any speed of the variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com