Spline shaft gear selecting bevel gear transmission and bicycle transmission

A technology of bevel gears and transmissions, applied in the field of bicycle transmissions, can solve the problems of complex structure of two-axis or three-axis transmissions, difficulty in applying bicycles, and large volume, and achieve the effects of light weight, reduced number of structures, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

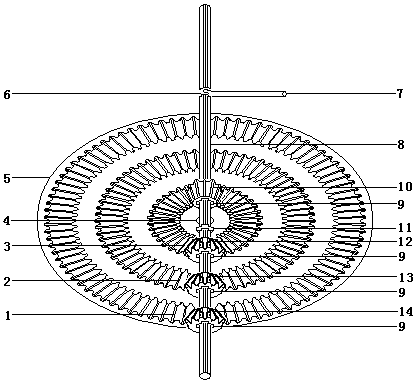

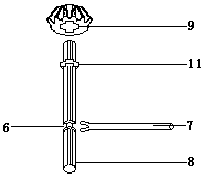

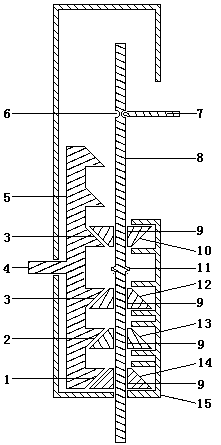

[0021] Embodiment one: figure 1 , figure 2 with image 3 Among them, the transmission is mainly composed of the first shaft (4), the second shaft (8), a multi-turn bevel gear (5) on the first shaft, multiple bevel gears (10, 12, 13) on the second shaft , 14), gear shift fork (7) and transmission housing (15). The first shaft is the power input shaft, and the second shaft is the power output shaft. The first shaft (4) and the second shaft (8) intersect perpendicularly, and a multi-turn bevel gear (5) fixed to the shaft as a whole is sleeved on the first shaft. One of the multi-turn bevel gears (5) There are multiple rings of gear teeth distributed on the side, and each ring of teeth forms a ring gear. Each ring gear (1, 2, 3) takes the gear axis as the center and has different radii. The function of each ring gear is equivalent to a cone. gear. The second shaft can move in the axial direction, and there are multiple bevel gears (10, 12, 13, 14) on it, and each bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com