Optimized composite insulator spraying grading method

A water spray classification method and composite insulator technology, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve the problems of easy misjudgment, uneven water spray, low accuracy, etc., achieve less experimental instruments and facilitate on-site detection , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

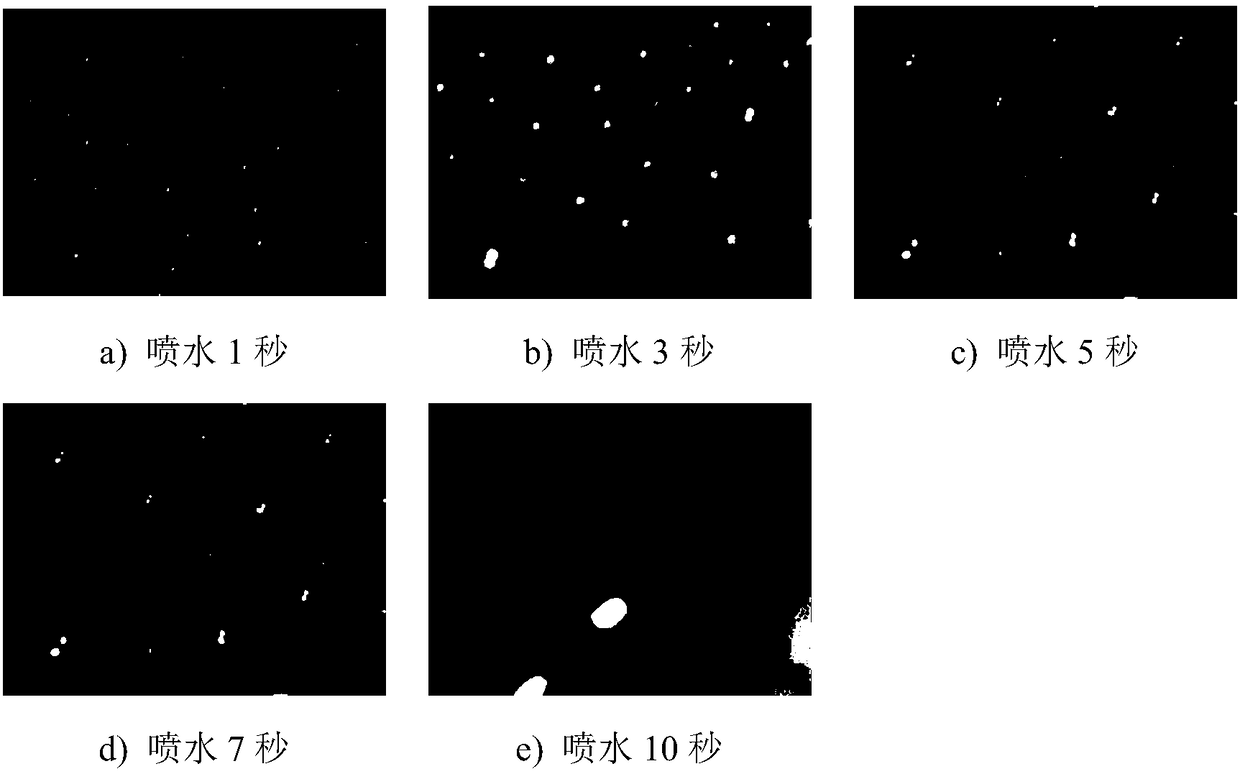

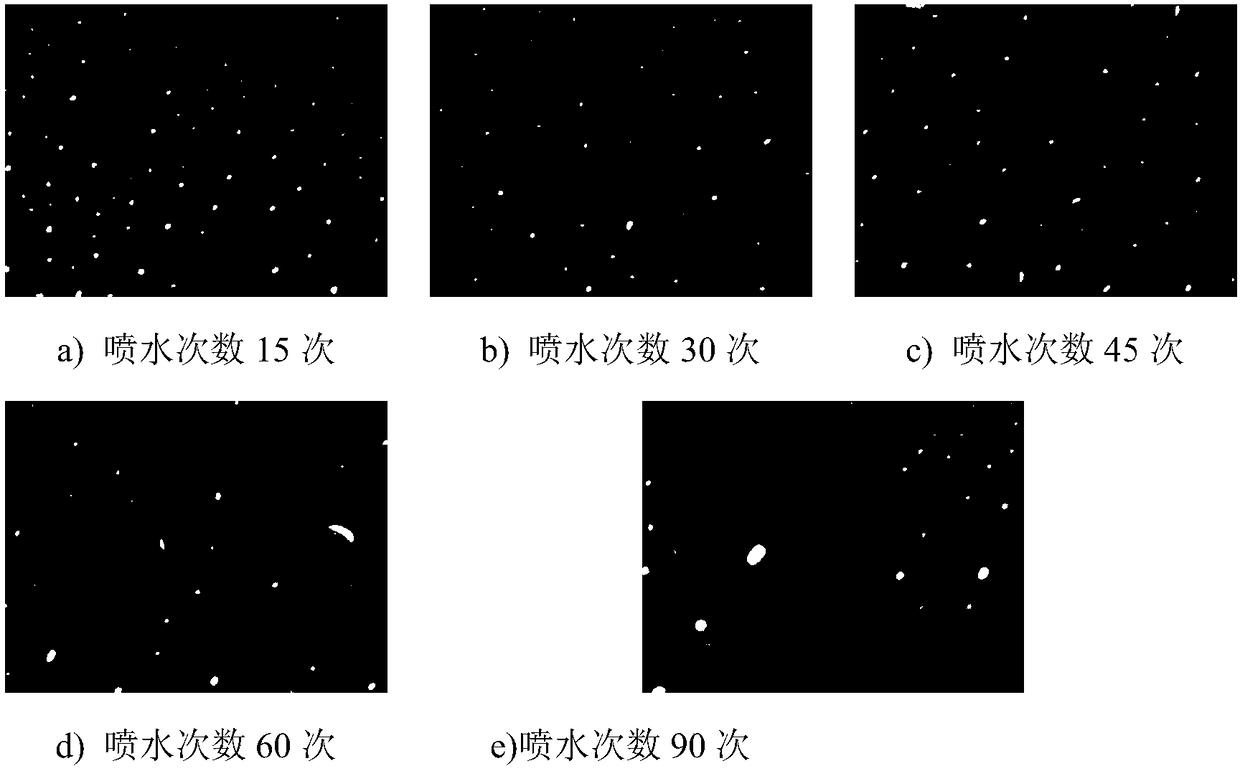

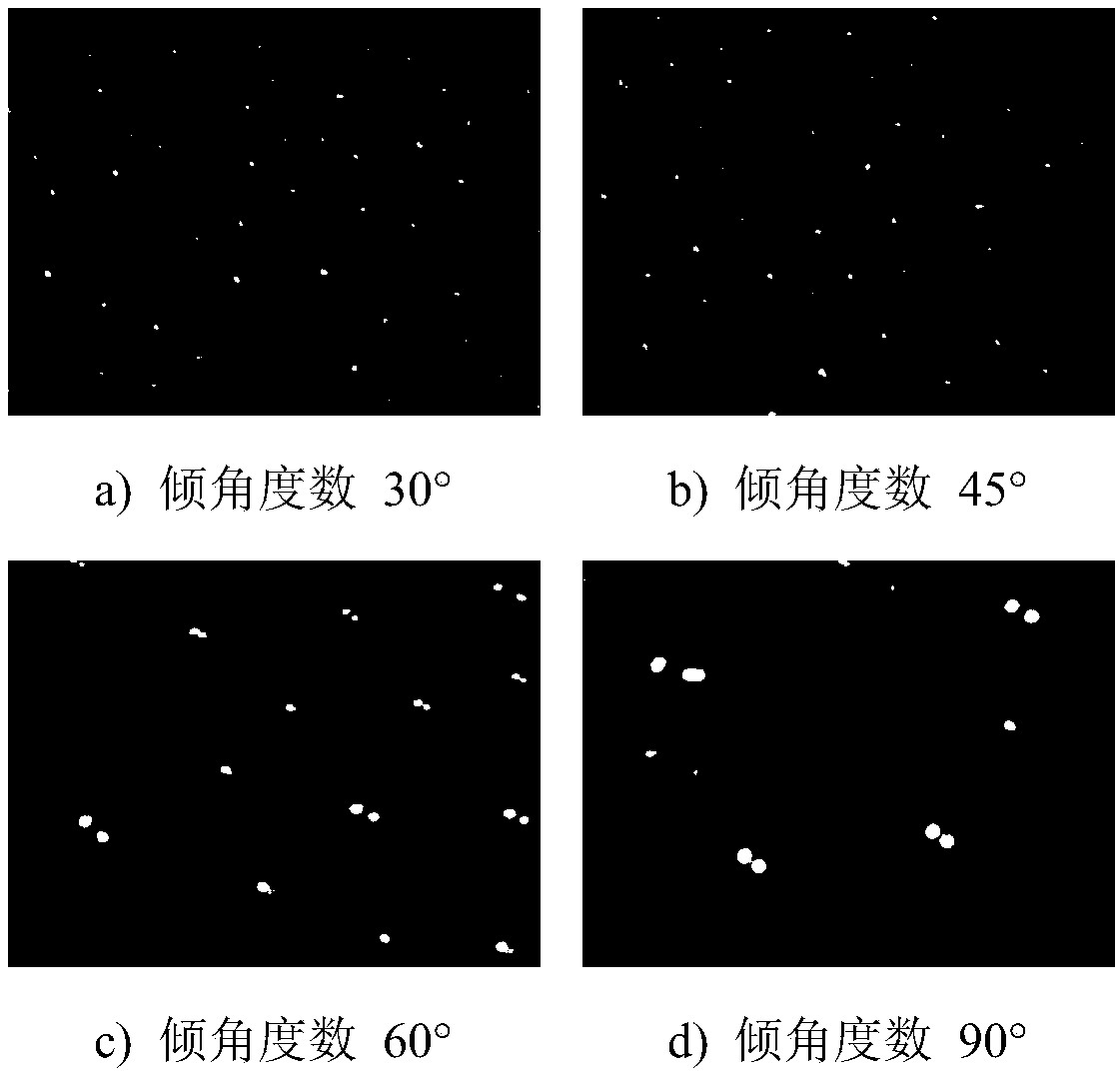

[0042] Take out the test piece and the whole insulator soaked in pure water for more than 96 hours, and dry it in the shade for the same time in the same environment to obtain the insulator test piece and the whole insulator with the same hydrophobic state. Use the contact angle method to measure the static contact angle and dynamic contact angle of the insulator test piece; use a fine water mist spray can (spray particle size is 10-30μm) to spray water on the surface of the entire insulator, and the water spray time is 3s each time. The distance from the sample is 15cm, the inclination angle between the nozzle and the sample is 45°, spray 15 times continuously. Take photos within 15 seconds after spraying water, and determine the hydrophobicity according to the photos. The experimental results are shown in Table 1 and Table 2.

[0043] Table 1. Correspondence between static contact angle and hydrophobic grade obtained from the test

[0044]

[0045] Table 2. Corresponden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com