X-ray tube perspective filament current upper and lower limit value self-calibration method

A filament current and X-ray tube technology, applied in X-ray equipment, electrical components, etc., can solve the problems of high requirements for operators and inconsistent manufacturing process of X-ray tubes, and achieve the effect of improving work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

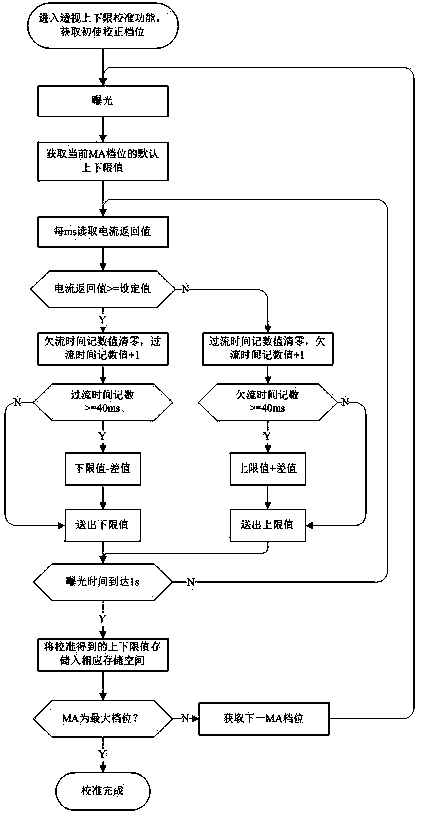

[0028] Such as figure 1 As shown, a method for self-calibrating the upper and lower limits of the X-ray tube fluoroscopy filament current comprises the following steps:

[0029] Step 1, pre-setting the upper limit value and lower limit value of the filament current for each fluoroscopy position;

[0030] Step 2, enter the fluoroscopy filament current upper and lower limit correction function system, and select the initial correction fluoroscopy gear;

[0031] Step 3: Depress the foot switch to perform exposure and obtain the upper limit setting value and lower limit setting value of the filament current of the current fluoroscopy gear; the correction exposure time of each fluoroscopy gear is 1s; the initial correction fluoroscopy gear is set to 0.5mA ;

[0032] Step 4, the system reads the current of the X-ray tube every 1 ms to obtain the current return value, and compares the current return value with the upper limit setting value and the lower limit setting value of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com