Crushing and grinding device for discarded brick

A technology of discarded bricks and grinding powder, applied in grain processing, etc., can solve the problems of affecting the appearance of the city, occupying land, and labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

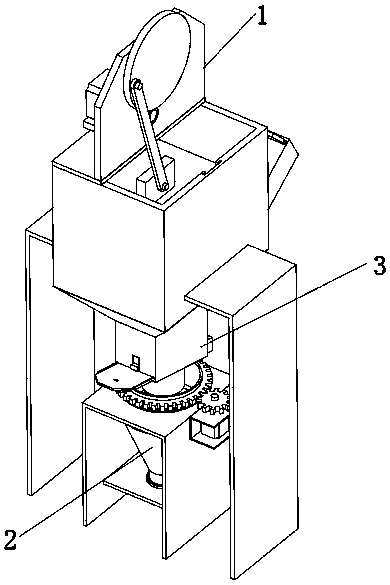

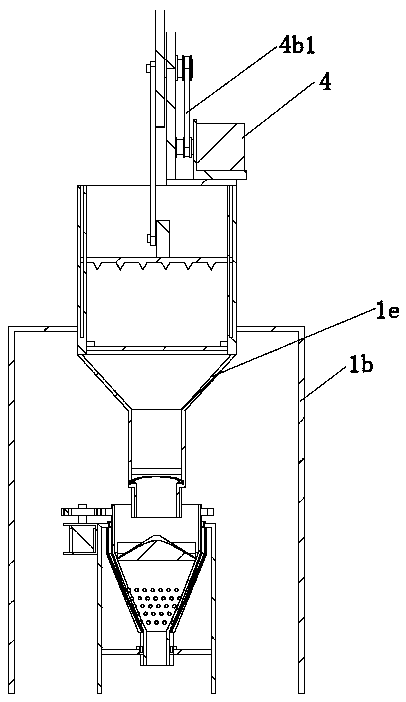

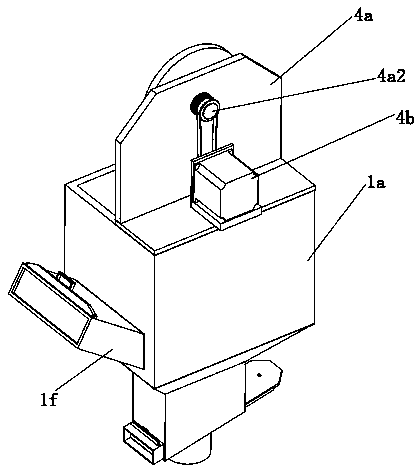

[0027] refer to Figure 1 to Figure 8 The shown crushing and grinding device for waste bricks includes a crushing mechanism 1, a grinding mechanism 2 and a material distribution mechanism 3, the crushing mechanism 1 is located directly above the grinding mechanism 2, and the material distribution mechanism 3 is located Between the mechanism 1 and the milling mechanism 2, the crushing mechanism 1 includes a storage cabinet 1a, a crushing assembly and a drive assembly 4 for driving the crushing assembly to move in the vertical direction, and both sides of the storage cabinet 1a are provided with There is an L-shaped support plate 1b for supporting the storage cabinet 1a, the crushing assembly is located in the storage cabinet 1a, the drive assembly 4 is located directly above the crushing assembly, and the grinding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com