Main shaft annular water spraying device

A water spray device and ring-shaped technology, which is applied in the field of machining spindle, tool cooling, and machining machine tool spindle, can solve the problems of low efficiency in the debugging stage, uneven tool cooling, cumbersome manual adjustment, etc., and achieve convenient and accurate automatic adjustment , Improve the degree of automation and processing efficiency, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following non-limiting examples illustrate the invention.

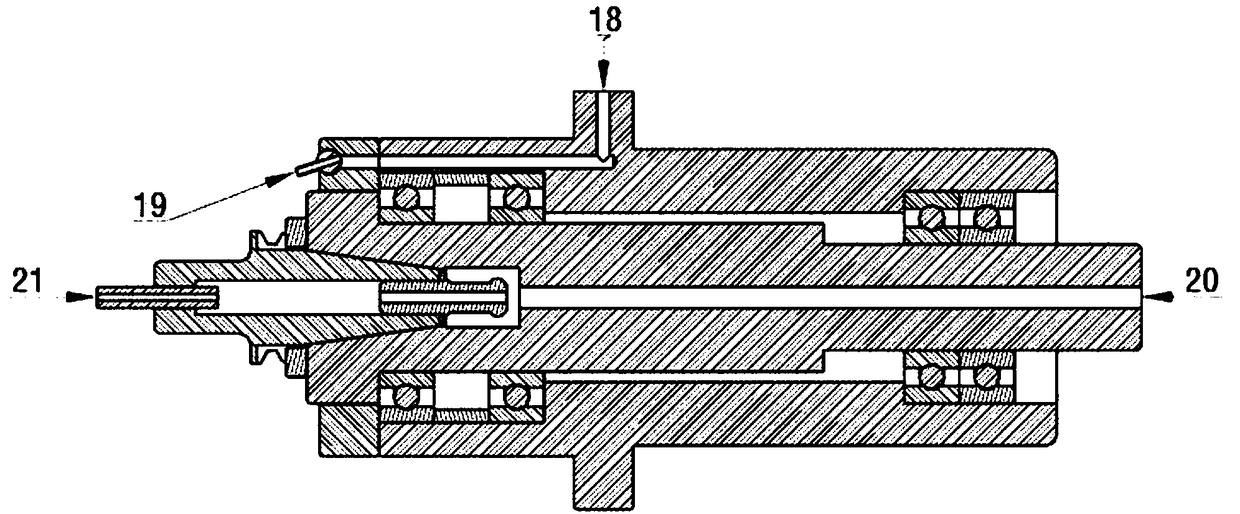

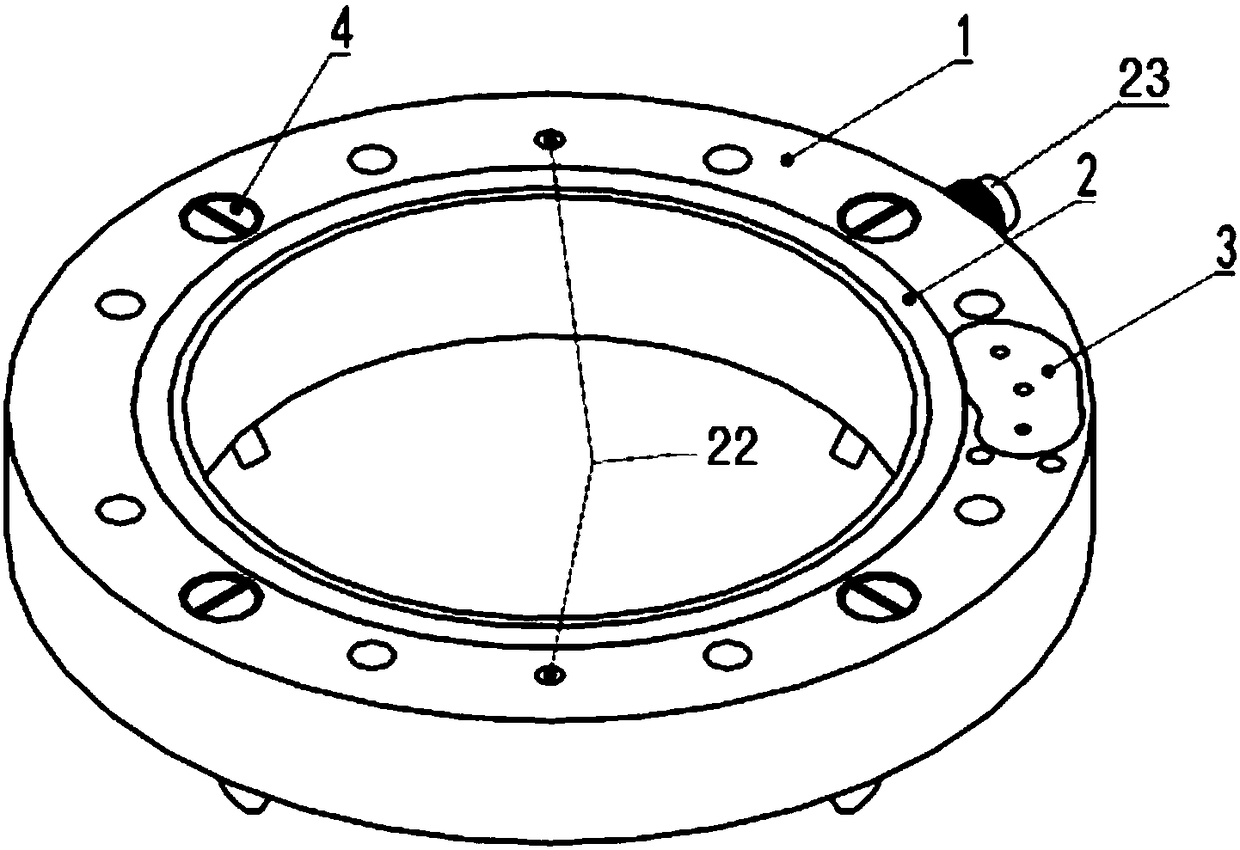

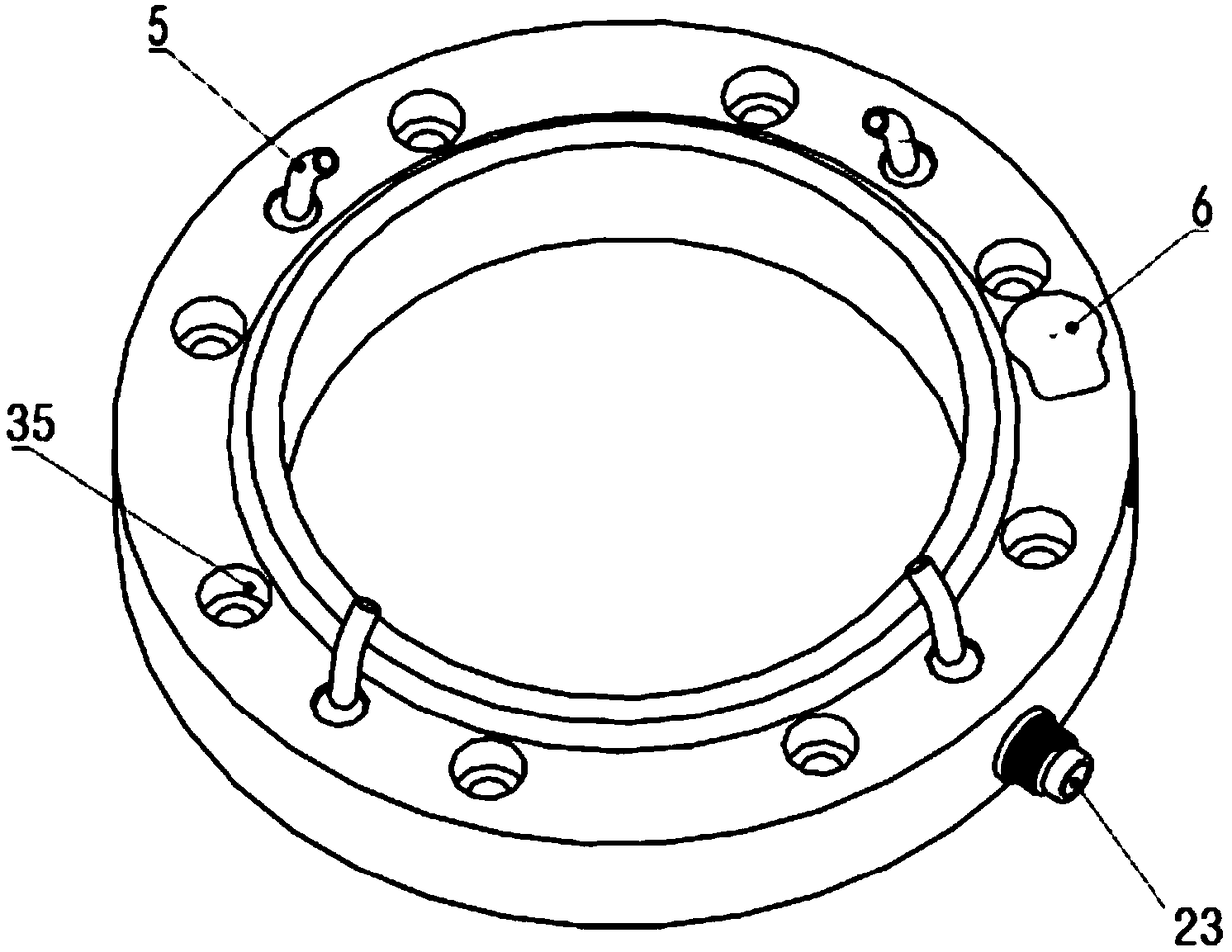

[0044] refer to Figure 1-17 as shown, figure 2 , 3 It mainly embodies the overall structure of the appearance of the present invention; Figure 4-6 It mainly reflects the structure of the overall internal waterway, the gear box installation groove 24, the nozzle group installation hole 27, the position of the cutting fluid inlet, and the limit card groove structure; Figure 7-9 It embodies the cooperative structural relationship between each part of the water spray device and the main body 1 of the annular end cover; Figure 10 It further embodies the distribution and shape of the internal water tank 28, the communication mode with each water spray device, and the transmission mode and installation position of the ring gear 7 and the gear set 13; Figure 11 It embodies the transmission relationship and transmission principle of all components from the drive motor 12 to the final nozzle 5; Figure 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com