Paint spraying device

A paint bucket and support table technology, which is applied to spray devices, devices for coating liquid on surfaces, pre-treatment surfaces, etc., can solve the problems of inconvenient operation, small spraying range, etc., to speed up drying speed, increase spraying range, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

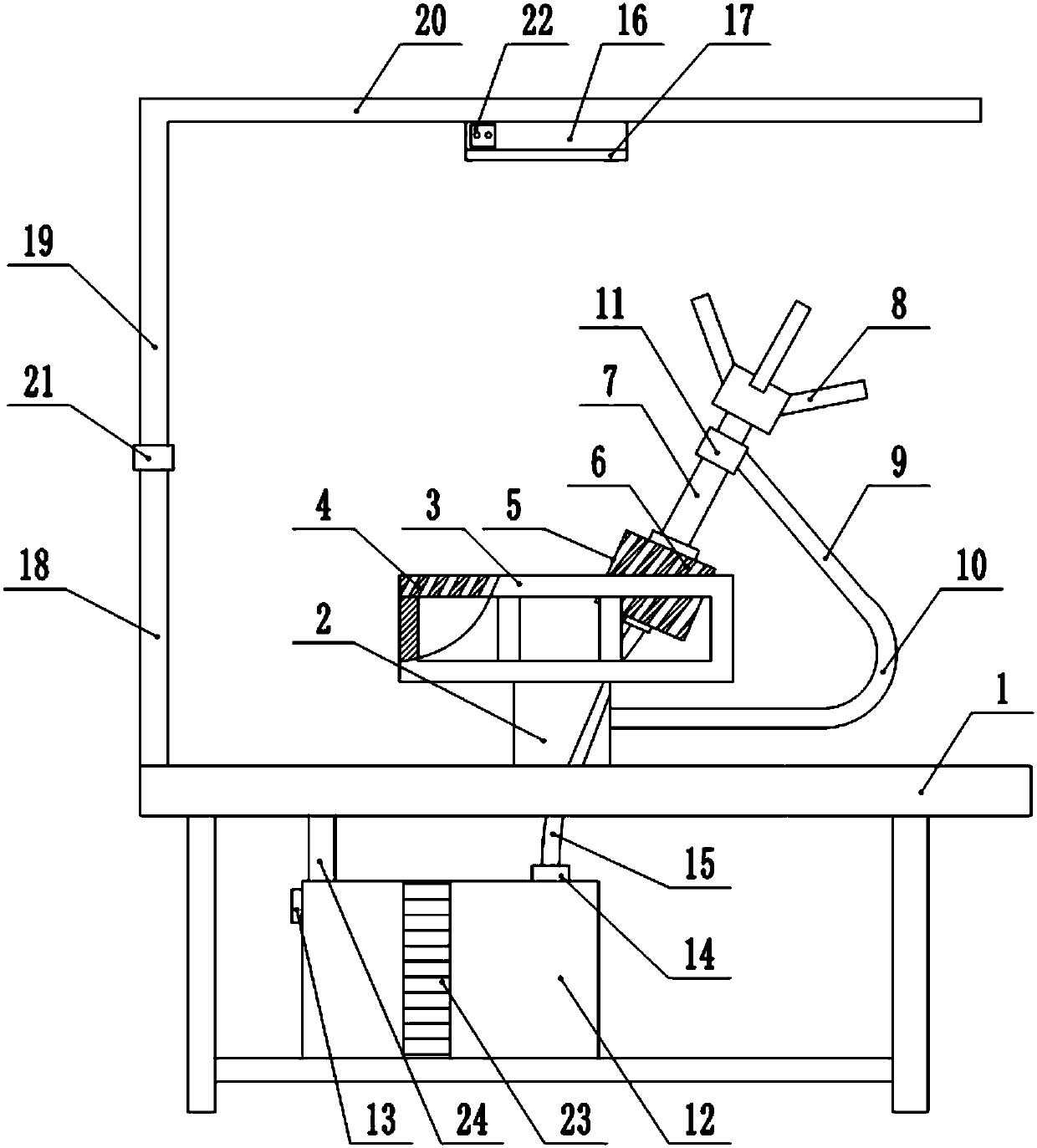

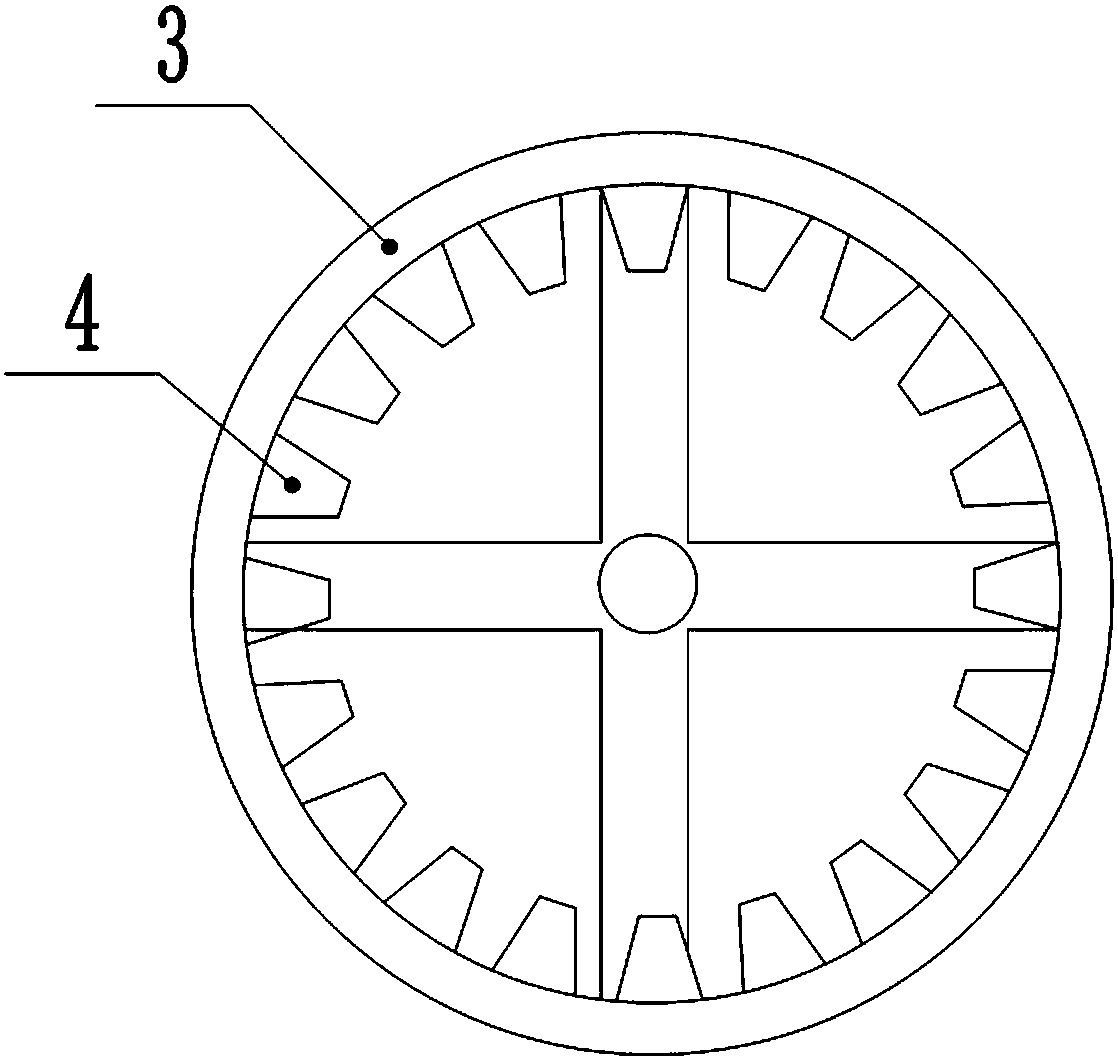

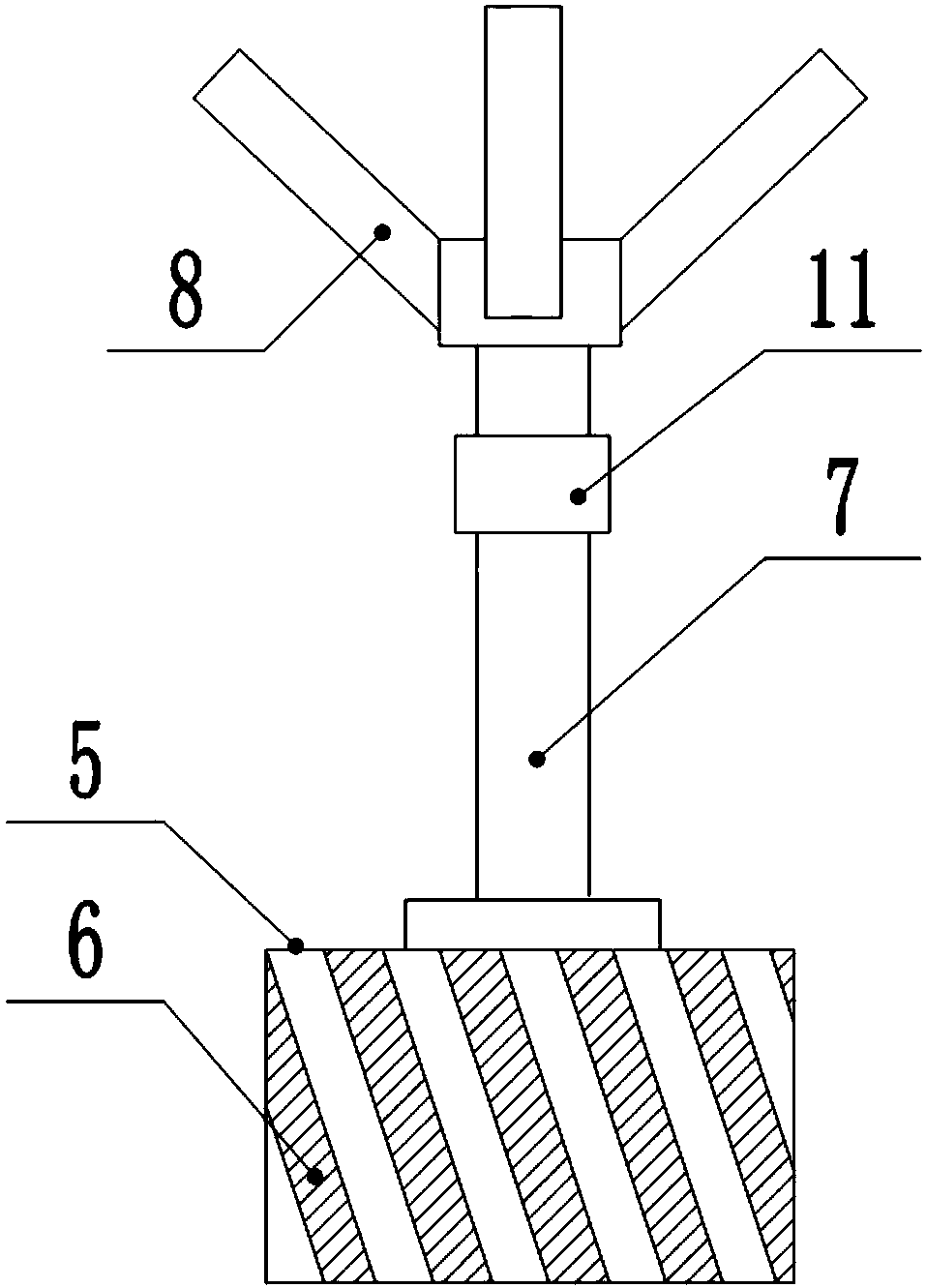

[0022] The reference signs in the accompanying drawings of the description include: support table 1, drive shaft 2, ring gear 3, first gear 4, paint bucket 5, second gear 6, paint spraying rod 7, paint spraying blade 8, connecting rod 9, bending part 10. Collar 11, material storage box 12, feed port 13, discharge port 14, discharge pipe 15, rotating shaft 16, magnet 17, first support rod 18, second support rod 19, cross bar 20, buckle 21, switch 22, visible window 23, return pipe 24.

[0023] Such as figure 1 Shown: a painting device, including a support platform 1, the support platform 1 is fixedly connected with a pole, the support platform 1 is provided with a painting mechanism, the painting mechanism includes a drive shaft 2 that is rotatably connected to the support platform 1, and the drive shaft 2 is connected to There is a first motor, a ring gear 3 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com