A stamping device for circular fittings

A technology for stamping devices and accessories, applied in the field of stamping devices for round accessories, can solve the problems of easy to leave curling or burrs, affecting the processing quality of round accessories, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

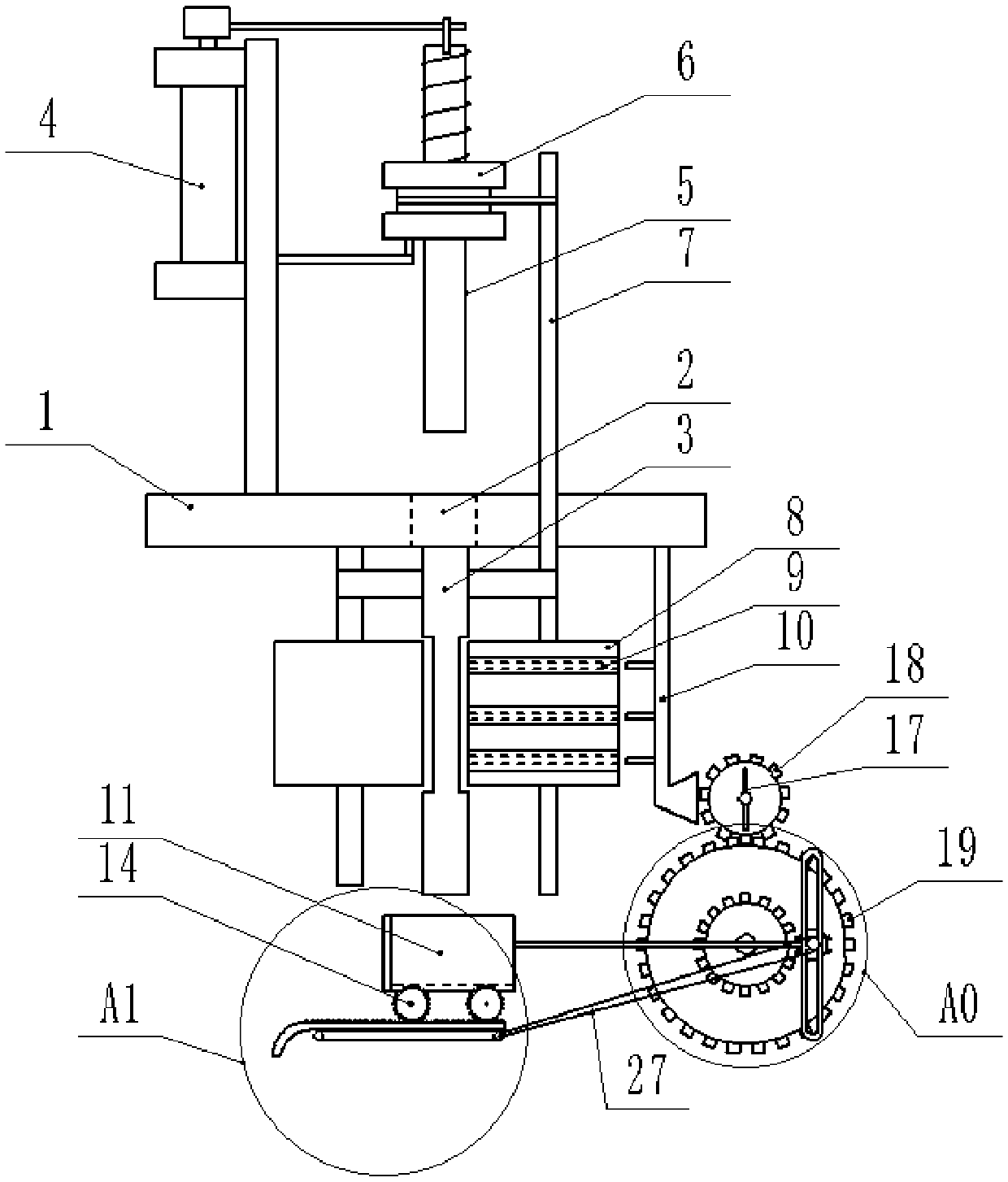

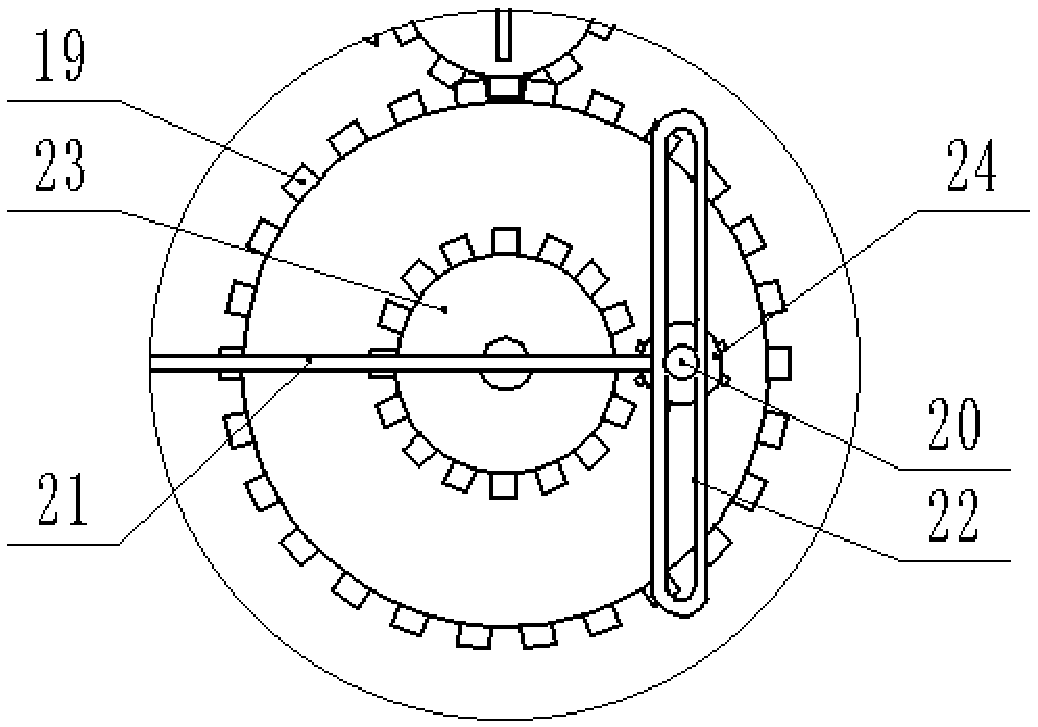

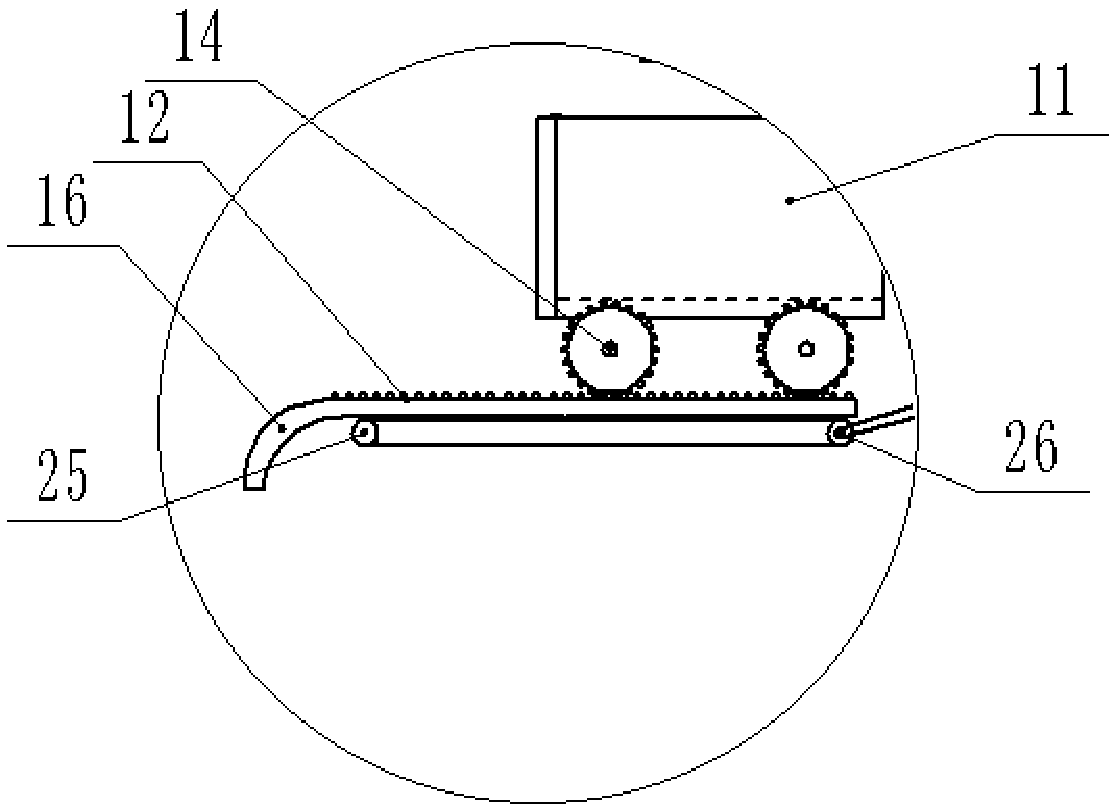

[0021] The reference signs in the drawings of the description include: machine 1, pressure hole 2, discharge pipe 3, cylinder 4, lead screw 5, sliding sleeve 6, shaft 7, friction roller 8, blowing pipe 9, air guide pipe 10 , transport cart 11, rack 12, movable wall 13, rotating gear 14, screen hole 15, bending part 16, fan 17, first gear 18, second gear 19, card shaft 20, push-pull rod 21, strip frame 22 , large gear 23, pinion 24, first shaft roller 25, second shaft roller 26, elastic belt 27.

[0022] The embodiment is basically as figure 1 Shown: a stamping device for round accessories, including a machine 1, on which a press hole 2 and a stamping mechanism are arranged, the lower end of the press hole 2 is welded with a discharge pipe 3, and the left and right sides of the discharge pipe 3 Openings are provided on the walls, and the stamping mechanism includes a ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com