A process for eliminating recrystallization of single crystal superalloy castings

A technology of superalloys and process methods, which is applied in the field of superalloys and can solve problems such as the generation of transverse grain boundaries and damage to high-temperature creep properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

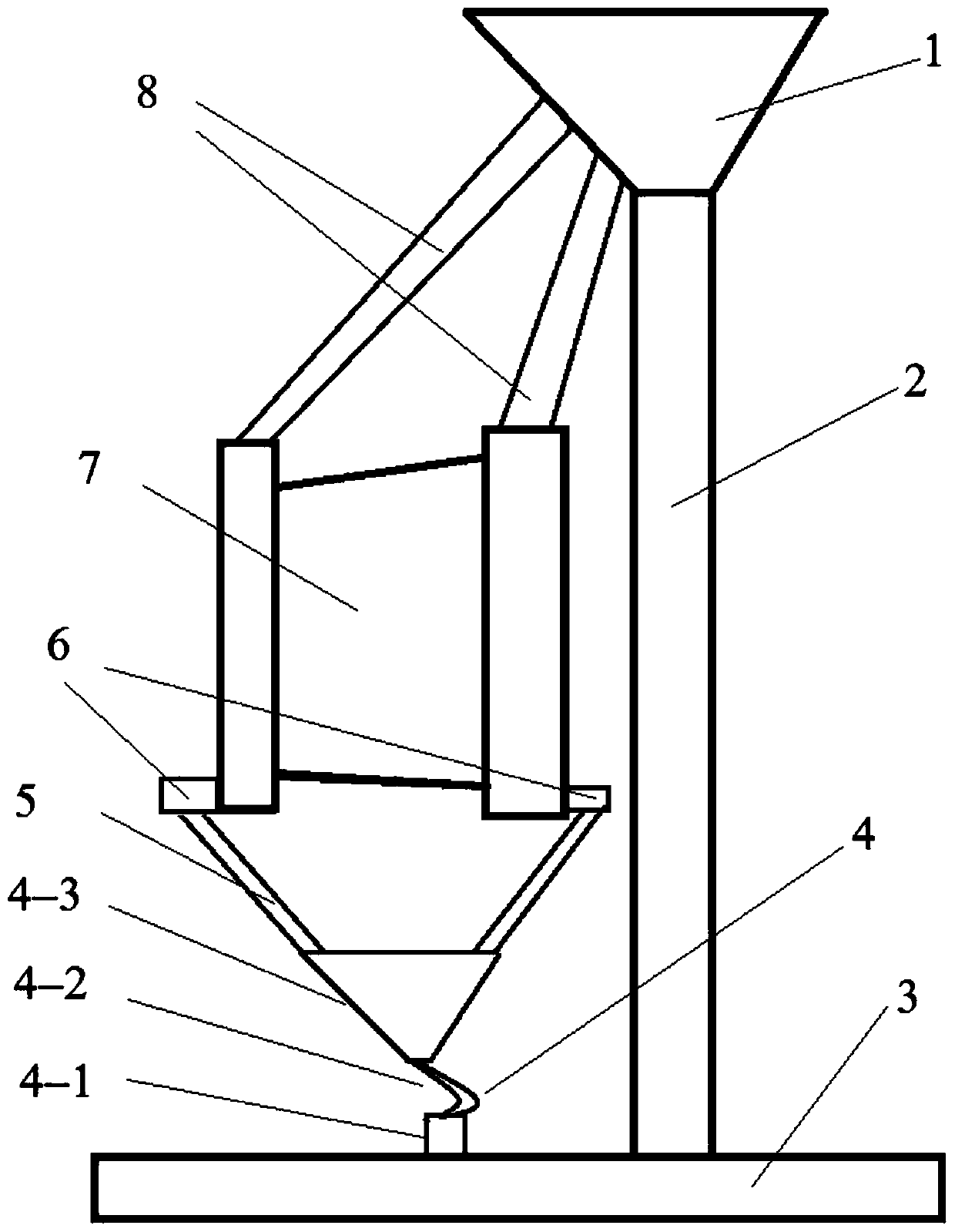

[0021] The auxiliary process part 6 and the single crystal casting 7 are integrally injection molded by the mold; the injection molding pressure is 0.5 MPa, the injection time is 20 seconds, and the pressure holding time is 30 seconds.

[0022] The crystal selector 4 is a spiral crystal selector, and the height of the crystal section 4-1 part is 10mm, and the diameter is 10mm; the crystal selection section 4-2 is spiral, and its diameter is 2mm; the thickness of the transition section 4-3 is 5mm;

[0023] The cross-sectional shape of the seeding bar 5 is circular, the diameter is 2mm, and the length of the seeding bar 5 is 20mm;

[0024] The cross-sectional shape of the process auxiliary part 6 is a square, and the side length of the square is 3 mm; the length of the process auxiliary part 6 is 10 mm;

[0025] The single crystal casting 7 mold shell is prepared by alumina coating and alumina shell material; the mold shell is dewaxed by steam dewaxing, the dewaxing pressure is...

Embodiment 2

[0027] The auxiliary process part 6 and the single crystal casting 7 are integrally injection molded by the mold; the injection molding pressure is 0.3 MPa, the injection time is 20 seconds, and the pressure holding time is 10 seconds.

[0028] The crystal selector 4 is a spiral crystal selector, and the height of the crystal section 4-1 part is 20mm, and the diameter is 15mm; the crystal selection section 4-2 is spiral, and its diameter is 3mm; the thickness of the transition section 4-3 is 3mm;

[0029] The cross-sectional shape of the seeding bar 5 is a rectangle, the side length of the rectangle is 5×3 mm, and the length of the seeding bar 5 is 20 mm;

[0030] The cross-section of the process auxiliary part 6 is a rectangle, and the side length of the rectangle is 6×4mm; the length of the process auxiliary part 6 is 20mm;

[0031] The single crystal casting 7 mold shell is prepared by alumina coating and alumina shell material; the mold shell is dewaxed by steam dewaxing,...

Embodiment 3

[0033] The process is the same as in Example 1, except that the cross-sectional shape of the process auxiliary part 6 is circular, and the diameter of the circle is 2 mm; the length of the process auxiliary part 6 is 15 mm;

[0034] Standard heat treatment is carried out after the single crystal casting 7 is prepared, and then the process auxiliary part 6 is cut off, and finally a complete single crystal casting without recrystallization is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com