Production technology of slurry type compound fertilizer

A production process and compound fertilizer technology, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problem of limiting the nitrogen content in compound fertilizer, and achieve the effects of easy storage, good broad-spectrum, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

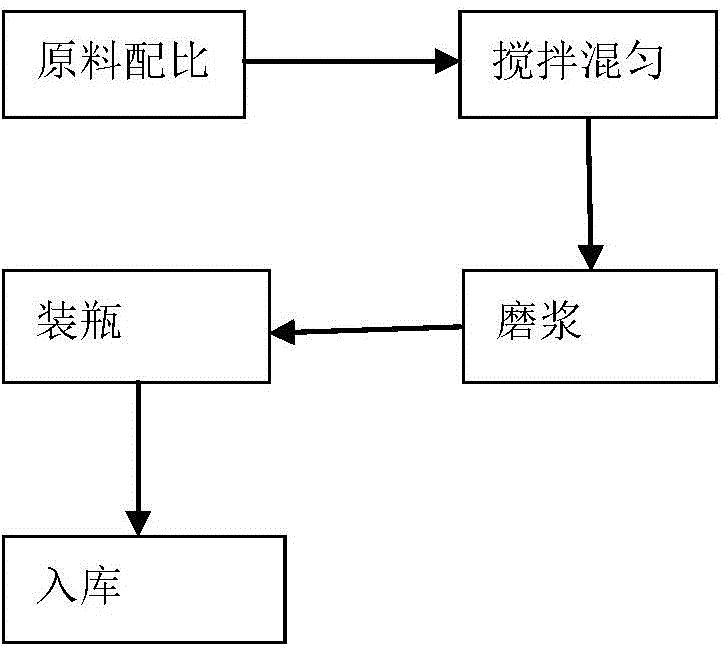

Method used

Image

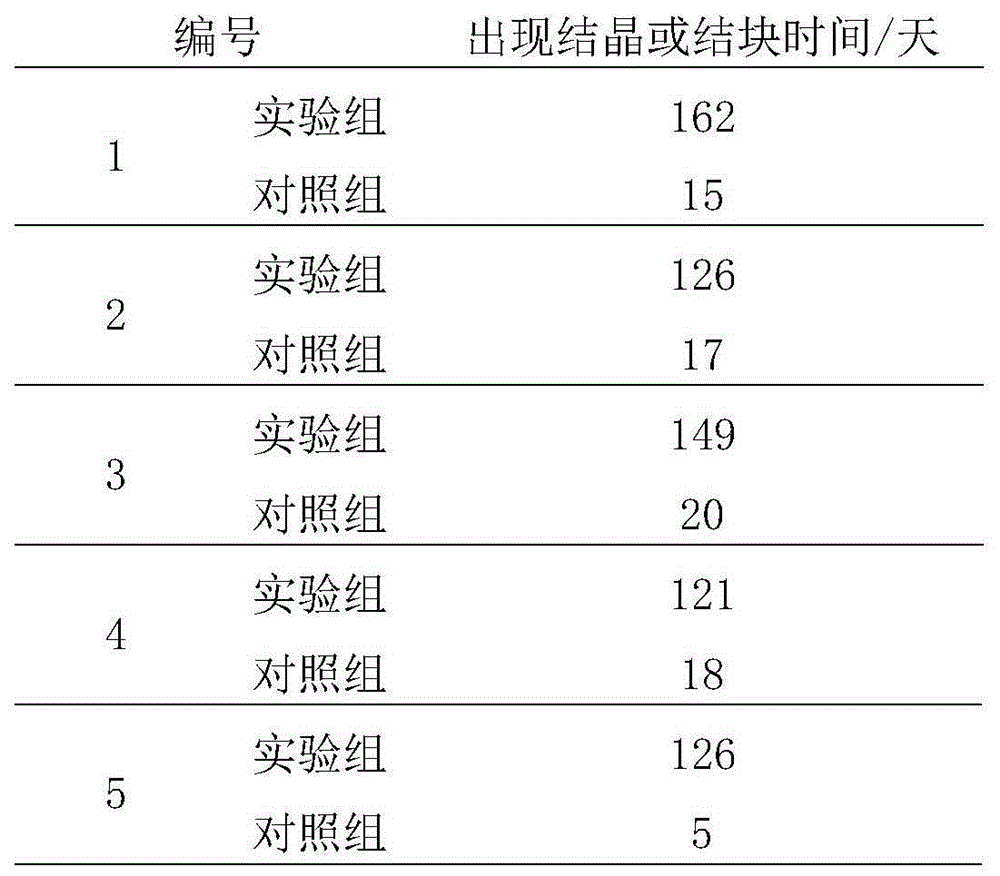

Examples

Embodiment 1

[0022] A kind of production technology of mud type compound fertilizer, comprises the following steps:

[0023] (1) According to the nutrient ratio required by the plant, allocate the ratio of each raw material of nitrogen source, phosphorus source, potassium source and trace element, add 1% starch and 10% water in terms of the total mass of fertilizer, stir and mix, The mixture is obtained; the fertilizer to be added is selected from urea, potassium sulfate, potassium dihydrogen phosphate, magnesium sulfate and zinc sulfate, and its specific ratio is prepared according to different plant physiological characteristics, wherein the nitrogen source, phosphorus source, potassium source and trace elements The mass ratio is nitrogen source: phosphorus source: potassium source: trace element=10:10:20:5;

[0024] (2) adding the mixture obtained in step (1) to a refiner for refining; refining to a particle size of less than 0.15mm to obtain a slurry-type compound fertilizer liquid;

...

Embodiment 2

[0027] A kind of production technology of mud type compound fertilizer, comprises the following steps:

[0028] (1) according to the nutrient ratio required by the plant, allocate the ratio of each fertilizer of nitrogen source, phosphorus source, potassium source and trace element, add 2% gelatinized starch and 25% water in terms of the total mass of fertilizer, stir and mix Evenly, the mixture is obtained; the added fertilizer is ammonium nitrate, ammonium chloride, potassium dihydrogen phosphate, potassium sulfate and magnesium sulfate, and the specific ratio is adjusted according to the needs of plant growth, wherein the nitrogen source, phosphorus source, potassium source and trace elements The mass ratio is, nitrogen source: phosphorus source: potassium source: trace element=25:20:35:10;

[0029] (2) adding the mixture obtained in step (1) to a refiner for refining; refining until the particle size is less than 0.15mm to obtain a slurry-type compound fertilizer;

[0030...

Embodiment 3

[0032] A kind of production technology of mud type compound fertilizer, comprises the following steps:

[0033] (1) According to the nutrient ratio required by the plant, allocate the ratio of each raw material of nitrogen source, phosphorus source, potassium source and trace elements, add 3% gelatinized starch and 40% water in terms of the total mass of fertilizer, stir and mix Uniform; add fertilizer and choose urea, liquid ammonia, diammonium phosphate, potassium chloride and zinc sulfate; the specific ratio is adjusted according to the needs of plant growth, wherein the mass ratio of nitrogen source, phosphorus source, potassium source and trace elements is , nitrogen source: phosphorus source: potassium source: trace element=40:30:50:15;

[0034] (2) The mixture obtained in step (1) is added into a refiner for refining; refining for 8 minutes to obtain a slurry-type compound fertilizer liquid;

[0035] (3) Bottling the slurry-type compound fertilizer liquid processed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com