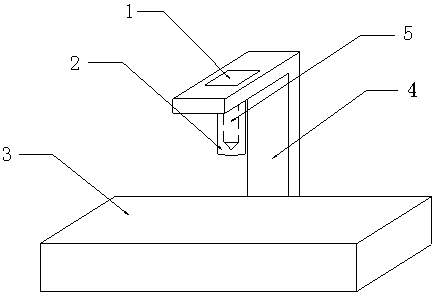

Laser head fixing device of laser cutting machine

A technology of laser cutting machine and fixing device, which is applied to laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of increasing labor intensity of operators, difficult disassembly, complicated fixing structure, etc. Good fixing effect and easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

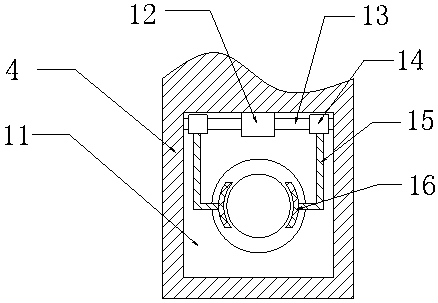

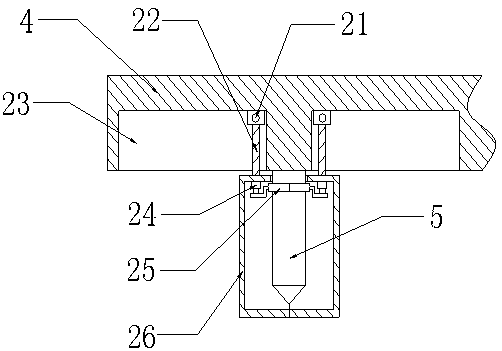

[0024] Specific embodiments: The operator first holds the laser head 5, puts the upper end of the laser head 5 in the through hole, keeps it still, and then runs the bidirectional motor 12, the bidirectional motor 12 drives the screw 13 to rotate, and the screw 13 rotates to drive the nut seat 14 moves to the left, the nut base 14 drives the L-shaped support rod 15 to move to the left, and the L-shaped support rod 15 drives the fixed plate 16 to move to the left. When the fixed plate 16 is attached to the laser head 5, the bidirectional motor 12 continues to rotate, and then Make the fixing plate 16 continue to move to the left to fix the laser head 5. When it is necessary to disassemble, the operator runs the bidirectional motor 12, the bidirectional motor 12 drives the screw 13 to rotate, and the screw 13 rotates to drive the nut base 14 to move to the right. The nut seat 14 drives the L-shaped support rod 15 to move to the right, and the L-shaped support rod 15 drives the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com