Bracket structure for plastic coiling block

A support structure and reel technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of practicality and applicability limitations, affecting the efficiency of replacement, heavy plastic film weight, etc. Good practicability, reasonable structure setting, quick replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

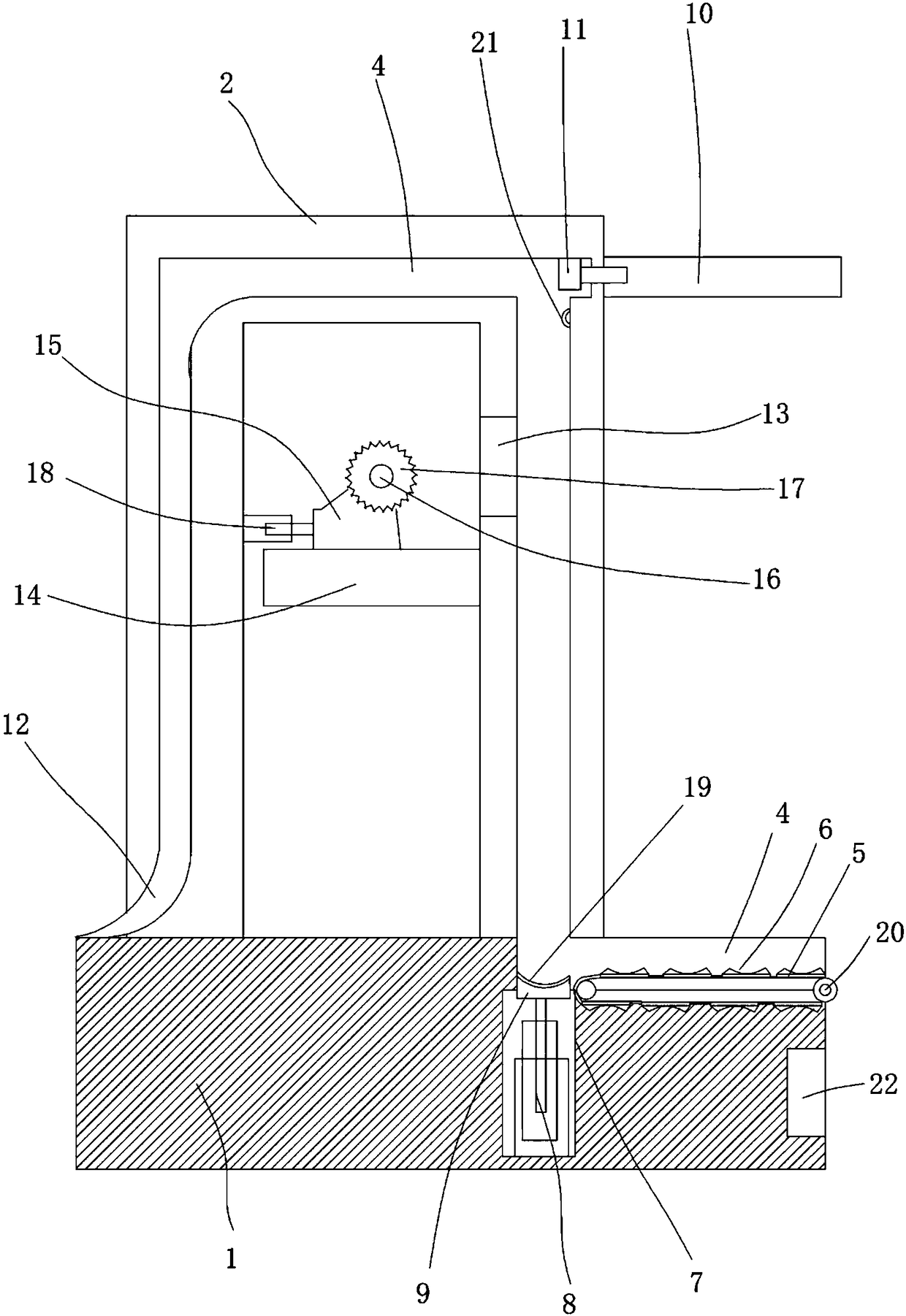

[0014] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0015] See figure 1 , a support structure for a plastic reel, comprising a base 1, two n-shaped frame bodies 2 with the same structure are arranged on the base 1, and the shaft rods at both ends of the reel are respectively in the n-shaped frame body when in use On the base 1, a lateral movement groove 3 with an open top surface is provided, an n-shaped guide groove 4 is arranged on the n-shaped frame body 2, and a transmission chain 5 is arranged in the lateral movement groove 3, U-shaped slots 6 are evenly arranged on the transmission chain 5, the end of the lateral movement slot 3 extends to the entry end of the n-shaped guide slot 4, and a vertical pressing hole 7 is arranged in the base 1 , the vertical pressure hole 7 is located directly below the entry end of the n-shaped guide groove 4, a top pressure cylinder 8 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com