PVD (physical vapor deposition)-based surface gradient film preparation device

A technology of thin film preparation and surface gradient, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem that the flux of the source cannot be changed arbitrarily, and achieve the effect of enhancing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

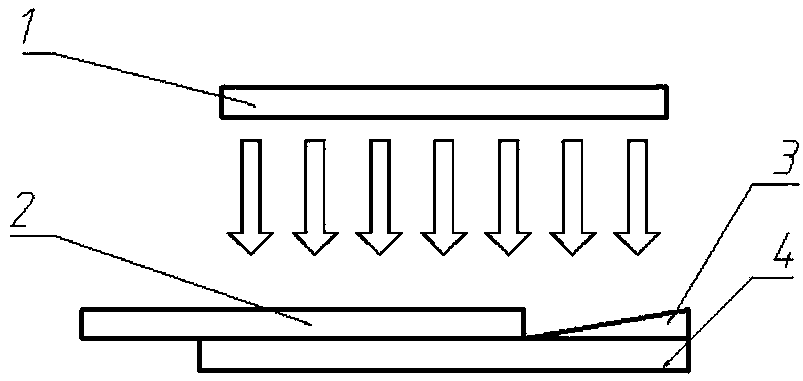

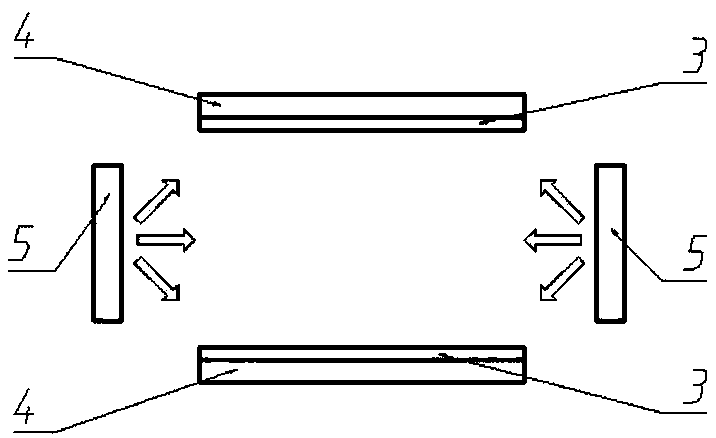

[0023] refer to Figure 2 ~ Figure 6 , a surface gradient film preparation device based on PVD, comprising a vacuum chamber 20, a substrate 19, a main chamber 18 and a source component, the substrate 19 and the main chamber 18 are respectively arranged on the upper and lower sides of the vacuum chamber 20 On both sides, said source component is arranged in said main chamber 18;

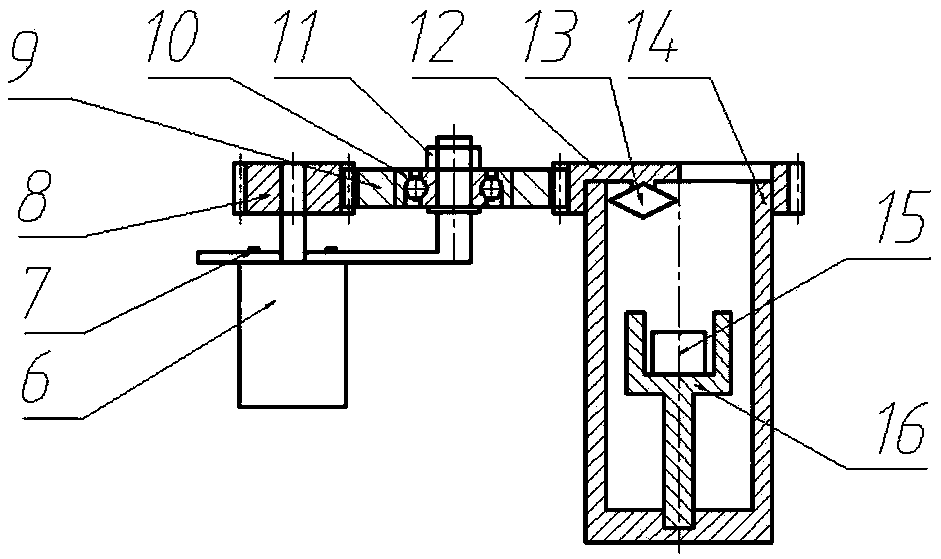

[0024] The source components include a stepper motor 6, a pinion 8, a bull gear 9, a sub-chamber 14, a source material 15 for coating the substrate, a crucible 16, a semicircle shield for shielding the microscopic particles of a part of the source that escapes. Plate 12 and a crystal oscillator plate 13 for real-time measurement of the flux of the source, the stepper motor 6 is fixed on the inner wall of the main chamber 18 through a bracket, and the pinion is fixed on the motor shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com