Steam and heat supply system for depth thermoelectric decoupling

A heating system and thermal system technology, applied in the field of deep thermo-electrolytic coupling steam supply heating system, can solve the problem of low flow and pressure of reheater, easy burnout of reheater, and increase of flow deviation of superheater and reheater. Large and other problems, to achieve the effect of less emissions, reduced material requirements, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

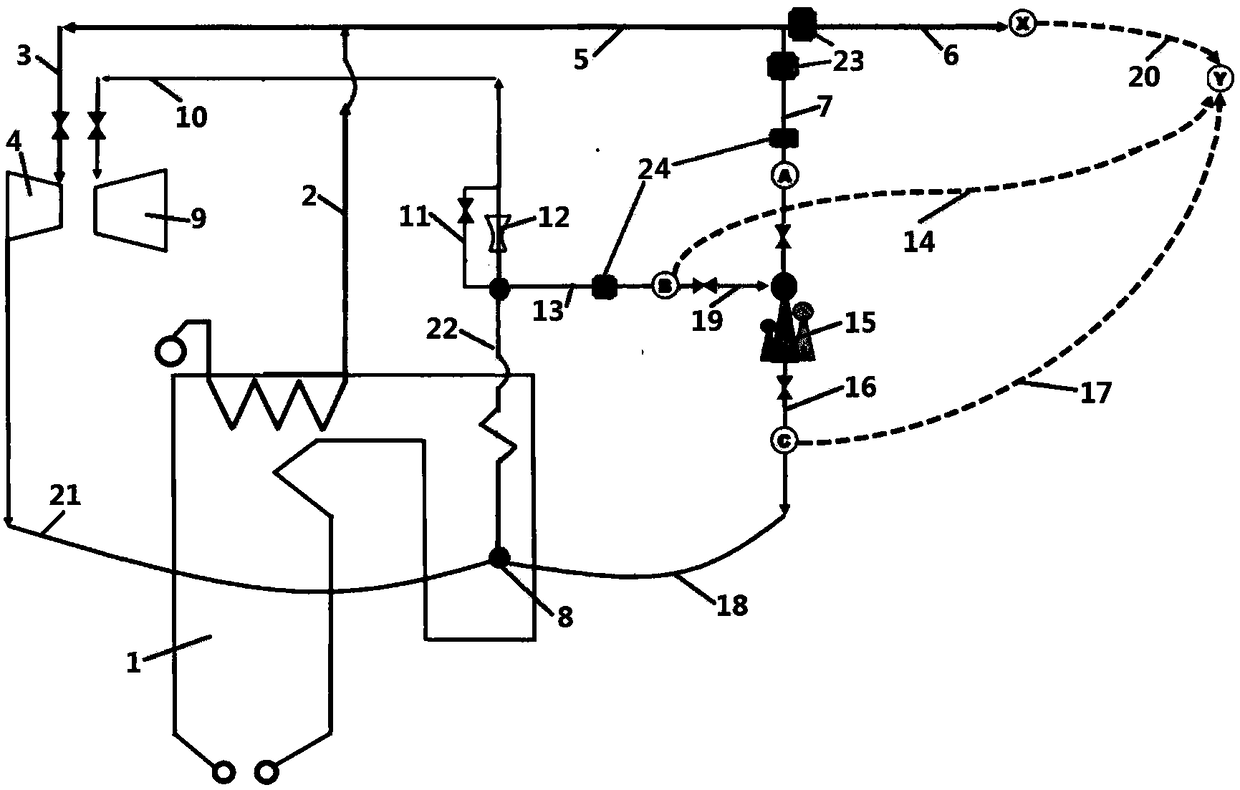

[0025] A thermal power plant has two 300MW water-cooled units installed, and each unit participates in flexible peak shaving and industrial steam and heat supply operations.

[0026] Part of the main steam is diverted and water is sprayed to reduce the temperature, which is used for industrial steam supply; at the same time, it is also used as the power steam of the steam booster to suck part of the exhaust steam at the hot end of the reheater; the exhaust steam of the steam booster is returned to the cold end of the reheater, and at the same time Provide the corresponding parameters of industrial steam supply or central heating steam. The exhaust steam at the hot end of the reheater can also be used for steam intake, heat supply and industrial steam supply of the medium pressure cylinder respectively.

[0027] Such as figure 1 , The design of the boiler body and the steam turbine body will not be changed, and the design of the auxiliary boiler and steam turbine recovery syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com