High-altitude two-stage turbocharger cooling system and control method thereof

A turbocharger and cooling system technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of large resistance loss, knocking, and inaccessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

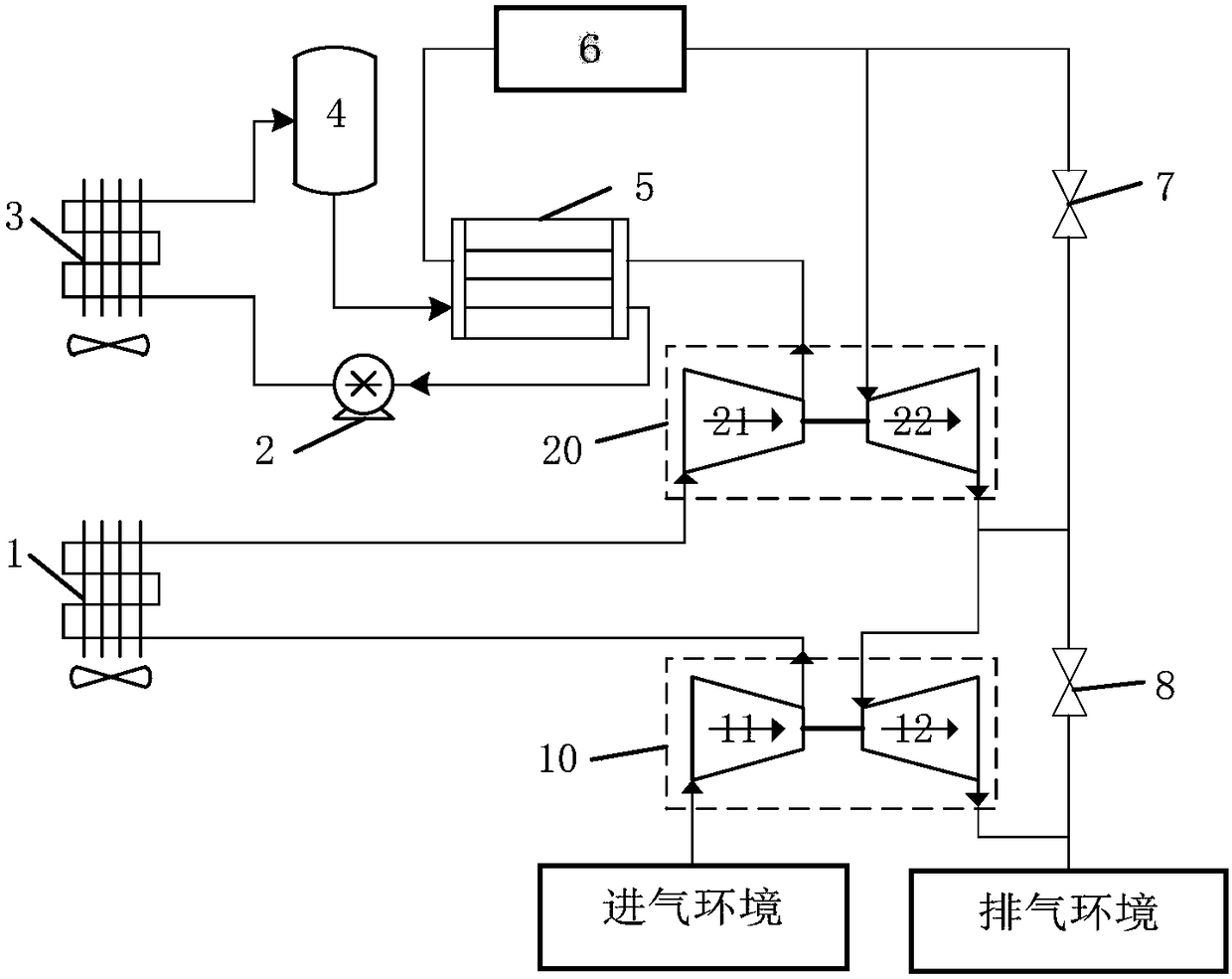

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be noted that the following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0054] The charge air cooling system described in this embodiment is suitable for a two-stage turbocharger in a high-altitude environment, and its composition and control method will be described below with reference to the accompanying drawings.

[0055] as attached figure 1 As shown, the high-altitude two-stage turbocharger cooling system of the present invention includes a first-stage turbocharger 10, a second-stage turbocharger 20, an engine cylinder 6, an interstage air-to-air cooler 1, a supercharging Rear water-air cooler 5, circulating cooling liquid tank 4, circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com