A gas booster system without gas consumption

A technology of gas pressurization and gas consumption, which is applied in the direction of liquid variable displacement machinery, piston pumps, pump components, etc., can solve the problems of large energy loss, low efficiency, and inability to realize large flow gas boosting, etc., and achieves a wide range of applications , high efficiency and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

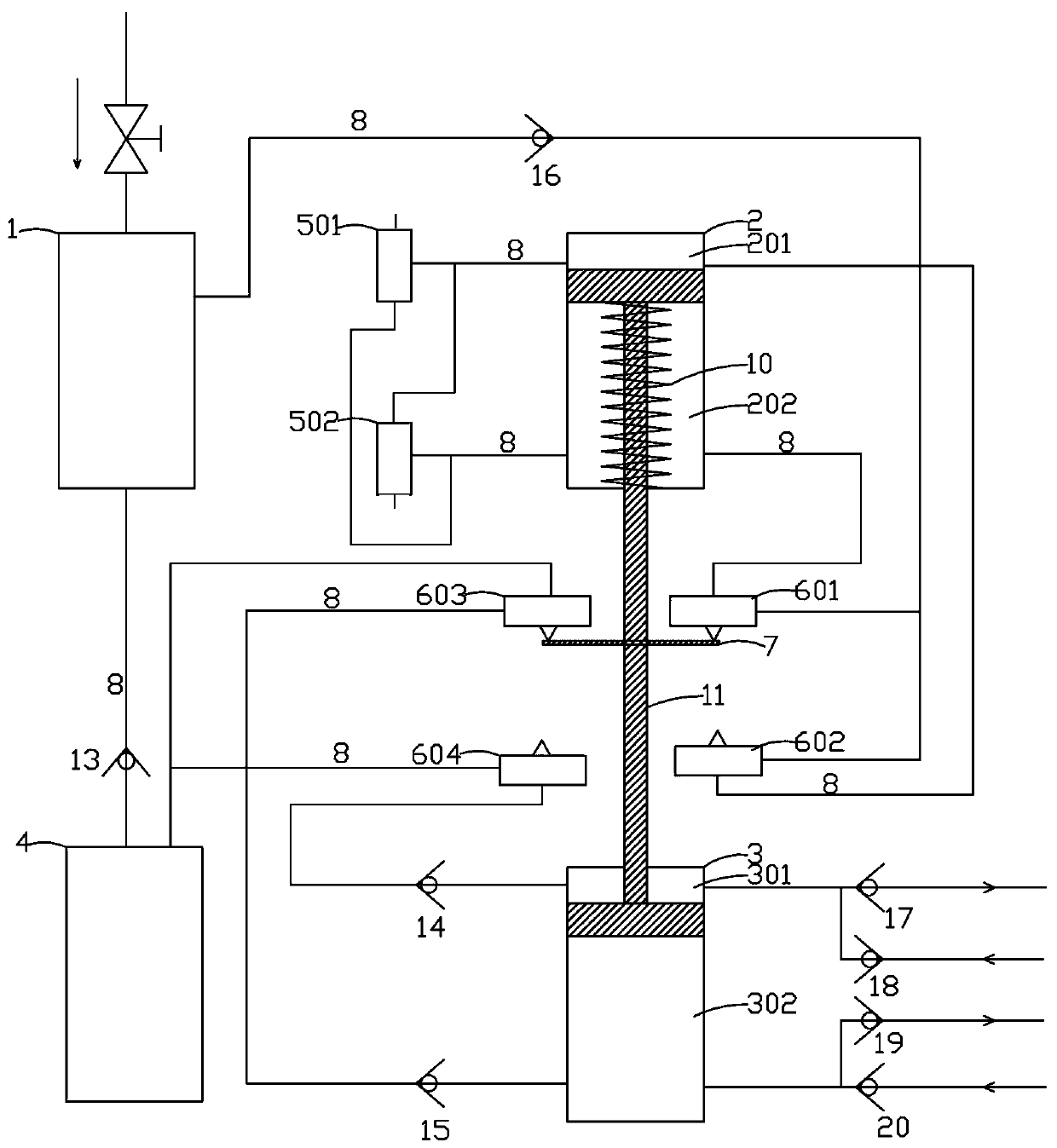

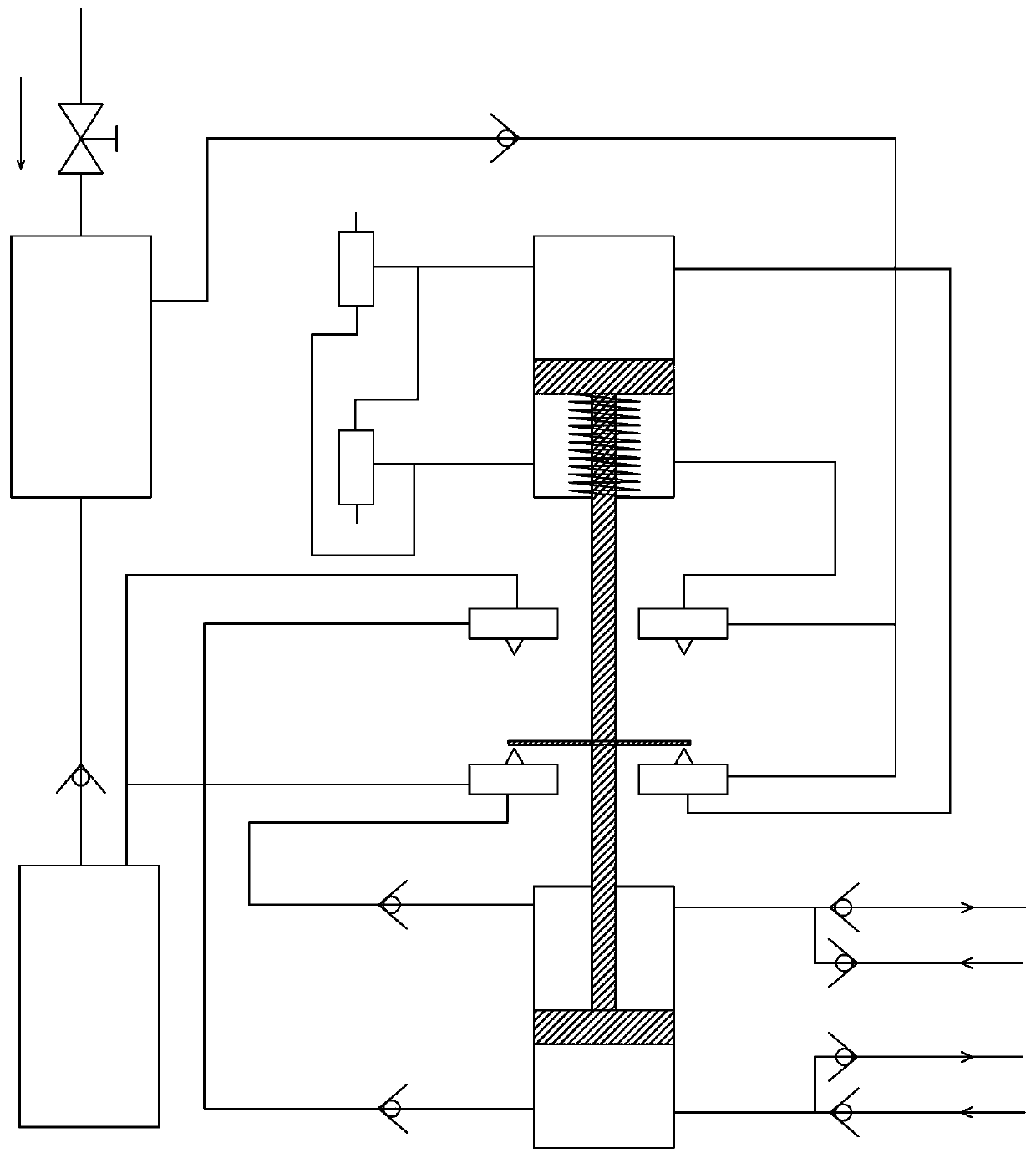

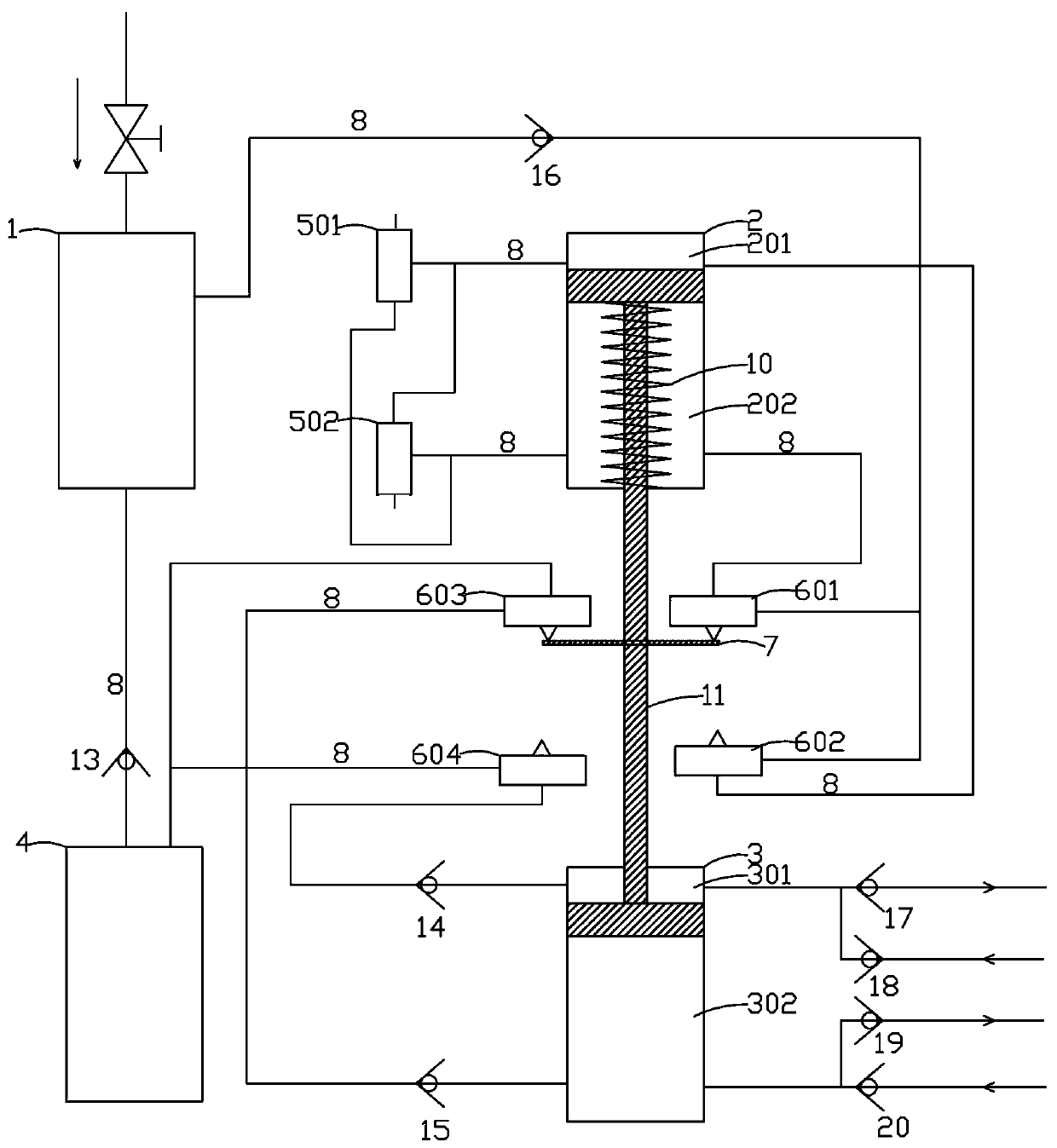

[0021] Such as Figures 1 to 2 As shown, the non-gas consumption gas pressurization system of the present invention is mainly composed of a vacuum generator 1, a vacuum cylinder 2, a piston type compression cylinder 3, a buffer gas tank 4, a vacuum valve, a trigger valve, a trigger 7 and a gas pipe 8. The vacuum generator 1 is connected to the upper vacuum chamber 201 of the vacuum cylinder 2 through the air pipe 8 one way, and the other way is connected to the lower vacuum chamber 202 of the vacuum cylinder 2, and a return spring 10 is arranged in the lower vacuum chamber 202 of the vacuum cylinder 2 . In the above, the upper vacuum chamber 201, that is, the vacuum cylinder 2, corresponds to the cavity above the piston, and the lower vacuum chamber 202, that is, the vacuum cylinder 2, corresponds to the cavity below the piston. The vacuum generator is a vacuum component that uses a positive pressure gas source to generate negative pressure. The vacuum generator is widely used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com