Series power water pump and heat pump system comprising same

A water pump and power technology, which is applied in the field of gas power generation and air conditioning, can solve the problems of frosting, low efficiency and poor effect of the surface cooler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

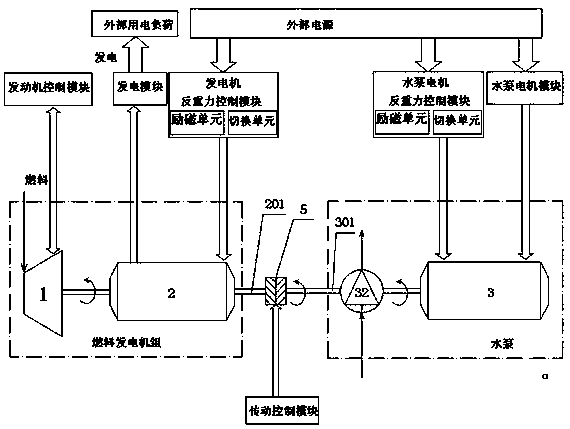

[0096] Embodiment 1: as figure 1 , the series power water pump includes a gas generator set, a heat pump unit and an electric control system, wherein the fuel generator set includes an engine 1 and a generator 2, wherein the generator 2 has a drive shaft 201 for power output; wherein the water pump includes a water pump motor 3 and Water pump body 32, water pump body 32 adopts double shaft extension structure, one end transmission shaft is connected with water pump motor 3, and the other end is connected with transmission shaft 201 of engine 1 through coupling device 5.

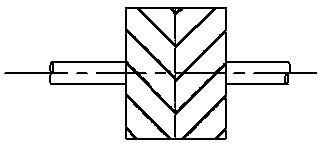

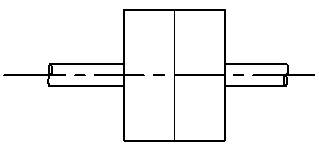

[0097] refer to figure 2 and image 3 They are schematic diagrams of connection and separation of the coupling device 5, respectively.

[0098] refer to Figure 4 , The electronic control system includes an engine control module, an air source heat pump control module, a water pump motor module, a power generation module, an anti-gravity control module, and a transmission control module. Wherein the engi...

Embodiment 2

[0114] The difference from Embodiment 1 is that the water pump motor module uses a frequency-adjustable power supply, which can automatically adjust the speed of the water pump motor 3 according to the load of the water pump.

Embodiment 3

[0116] refer to Figure 15 and Figure 16 , the difference from Embodiment 1 is that the coupling device 5 adopts a flange coupling without a transmission control module, including a driving disc 501, two sets of flexible connecting pieces 502, an intermediate connecting section 503, a driven disc 504, and connecting bolts 505 and nut 506. The driving disk 501, the flexible connecting piece 502, the intermediate connecting section 503 and the driven disk 504 all have a number of through holes through which bolts can pass. One set of flexible connecting pieces 502 are alternately fixed to the driving disk 501 and the intermediate connecting section 503 by bolts 505 and nuts 506; the other set of flexible connecting pieces 502 are alternately fixed to the driven disk 504 and the intermediate connecting section by bolts 505 and nuts 506 503 fixed. When the driving disc 501, the flexible connecting piece 502, the intermediate connecting section 503 and the driven disc 504 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com