Automobile headlamp core module structure

A technology of automobile headlights and module structure, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of non-integrated design, difficult design, and inability to achieve market popularization, and achieves a suitable size ratio. , low cost, sophisticated design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

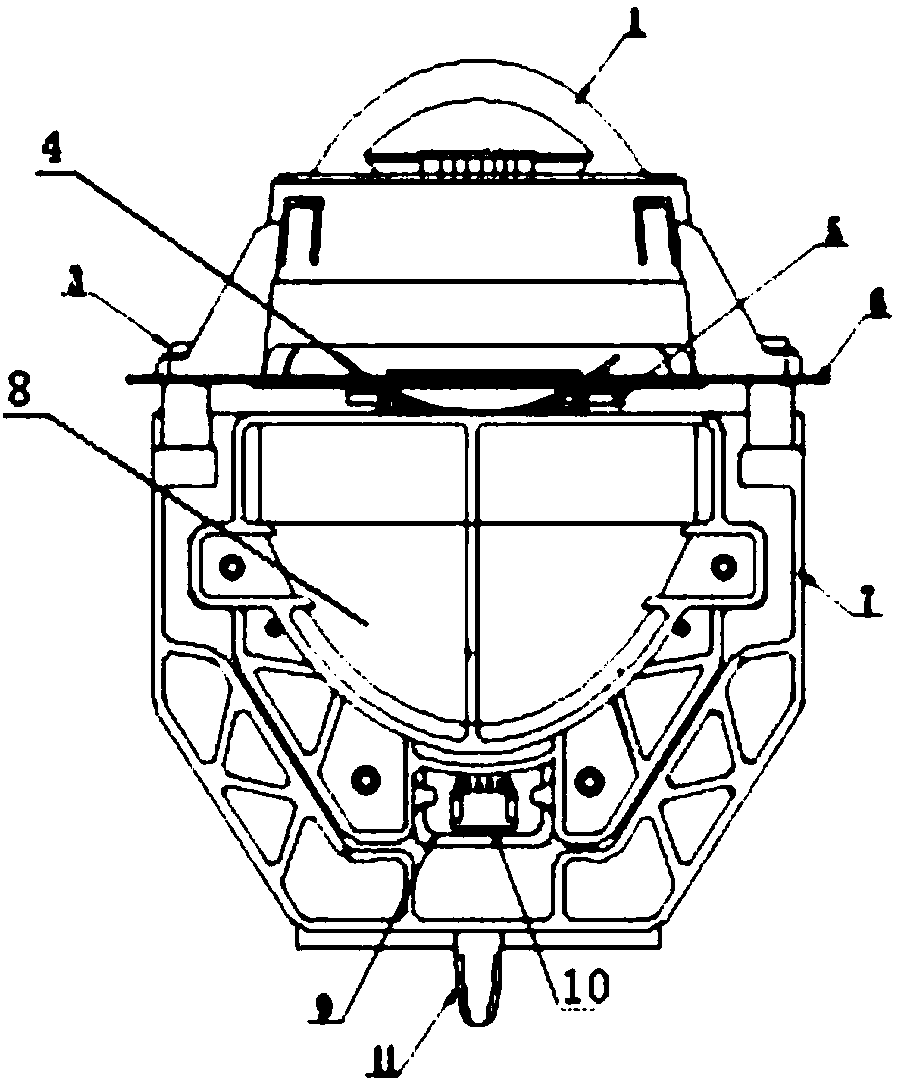

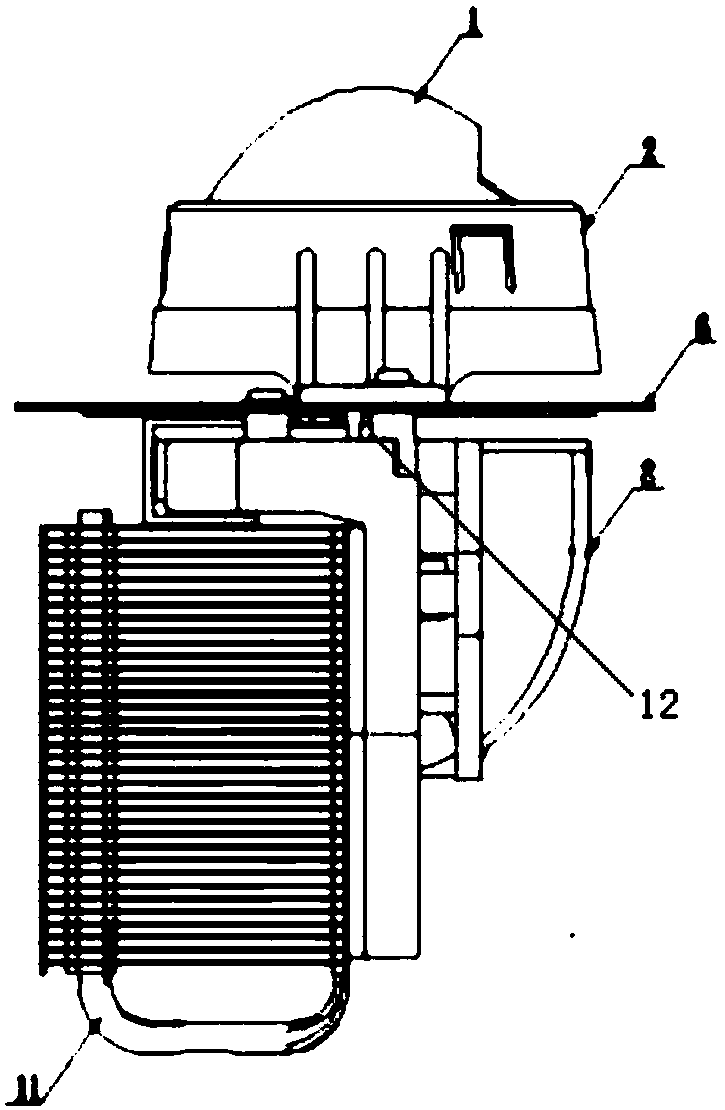

[0020] The application scheme of the present invention provides a core module structure of an automobile headlamp, including a fixing, 6, a transmission rod 5 is arranged on the fixing plate 6, and a far and near light switching baffle is arranged on the transmission rod 5, and the transmission rod 5 drives the far and near light switching baffle to rotate, the electric rod 5 is controlled by a solenoid valve 12, the lens 1 is arranged on one side of the fixed plate 6, and the rear reflector 8 is arranged on the other side of the fixed plate 6. A light board 9 is arranged in the rear reflector 8, a light source is arranged on the light board 9, a connector 10 is arranged on the light board 9, and a radiator assembly 11 is installed on the light source side of the light board 9, the radiator assembly 11 It includes an array of heat sinks, and a heat dissipation copper tube is arranged inside the heat sink, and the heat dissipation copper tube is U-shaped.

[0021] In addition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com